Last Updated on March 13, 2025 by Packoi Team

Corrugated boxes are sturdy, which makes them perfect for heavier objects. But will this packaging material suit your product and shipping preferences? If you’re unsure about it, we hear you!

In this guide, we will explain everything you need to know about corrugated boxes and how to personalize them for your brand. We’ll cover the different types of corrugated, as well as how to choose the right size and protect your items in transit.

To create your brand’s lasting impression and make it the best one out there, read on!

A Guide to Corrugated Boxes and What Are They Used for?

Corrugated packaging is a cardboard box with ruffled layers called flutes. These flutes are made of kraft paper, and the corrugated box is glued to them. The most common type of corrugate is a 3-ply, which has an outer layer, a middle layer, and an inner layer.

The middle layer is the corrugate, and the other two layers are liner boards. Liner boards can be made of recycled paper or new fiber. These boxes are globally used for packaging because they are strong and lightweight. And since these stackable boxes suit fragile and heavy items, they’re preferred over most packaging materials.

You might not give much thought to the humble corrugated box, but this essential piece of packaging plays a vital role in getting goods from point A to point B. Corrugated cardboard boxes are made from a fluted paper board sandwiched between two outer layers of liner board for extra resilience.

This combination gives the box strength while still being lightweight and easy to transport. Let’s take a closer look at how corrugated boxes are made.

- The first step in making corrugated fiberboard boxes is to create the fluted paper board, also known as the corrugating medium. This paper is made from recycled materials, such as cardboard and newsprint. To make the fluting, the recycled paper is fed into a machine, where it is then compressed and heated. Once heated, the paper is passed through rollers that give it its distinctive wavy shape.

- Once the fluting has been created, it is glued to the liner board using an industrial adhesive. Liner is a flat cardboard that is made from virgin wood pulp. It provides rigidity and support to the box and is available in two types: inner and outer. The inner liner is glued to the fluting, while the exterior liner board covers the outside of the box.

- After the inner and outer liner boards have been glued to the fluting, they are fed into a machine that will cut them to size and fold them into the desired shape. The last step is to seal the seams with tape or glue to reinforce the box’s structure. And that’s it!

This is the basic process of making corrugated boxes for packaging and shipping, but manufacturers can also customize it. For instance, if a brand wants its packaging to be extra durable, it can opt for triple-wall corrugated boxes, and the remaining process will be the same.

Likewise, one can customize these boxes with glossy finishes and different colors to suit the said specialty and retail packaging personalities.

What Materials Are Used in Making Corrugated Boxes?

Cardboard boxes are a necessary part of life; we use them to move, ship, and store things. With the popularity of online shopping and eCommerce, these boxes are produced and used more than ever. But have you ever wondered what those boxes are made of? If not, let’s look at the corrugated cardboard boxes’ materials.

- As we said, corrugated cardboard comprises three layers: an outer layer of liner board, a middle layer of fluting, and an inner layer of this board. The fluting is made up of slightly compressed paper that forms tiny air pockets; this is what gives corrugated cardboard its characteristic ribbing.

- The liner boards are made of a flat sheet called kraft paper– a type made from wood pulp known for its durability. The outer layer of the liner protects the box from moisture and provides a smooth surface for printing. Likewise, the inner layer serves as a cushion for the box’s contents and helps absorb impact.

Together, these three layers make up a sturdy yet lightweight material perfect for box-making. When it comes time to choose a material for your next project, keep corrugated cardboard in mind.

Things to Consider When Choosing a Corrugated Box Design

When shipping your products, you want to ensure they arrive safely and securely at their destination. That’s where custom-corrugated boxes come in. Corrugated boxes are strong and durable, making them ideal for protecting your products during transit.

But with so many different box designs available, how do you know which one is right for your business? Here are a few things to consider when choosing a corrugated box design:

- Box dimensions

- Construction material

- Weight and resilience

- Your budget

- Shipping regulations

- Reusability

- Brand voice/personality

Here’s a quick look at these factors:

1. Size and Dimension Requirements

One of the first things you’ll need to consider when choosing a corrugated box design is the size and dimensions of your product. You’ll want to ensure that your box is large enough to accommodate your product without being too big or bulky.

Additionally, take into account any special shipping requirements, such as if your product needs to be shipped refrigerated or frozen.

2. The Fragility of Your Product

Another thing to consider when choosing a corrugated box design is the fragility of your product. If your product is fragile and needs extra protection, you’ll want to choose a box design that includes additional padding or reinforcement. On the other hand, if your product is not fragile, you may be able to get away with a more basic box design.

3. Your Shipping Budget

When choosing a corrugated box design, you’ll also need to consider your shipping budget. Choosing a reinforced or padded box will inevitably cost more than a basic design.

However, it’s important to remember that investing in a higher-quality box now could save you money in the long run by preventing damage to your products during transit.

6 Types of Corrugated Box Designs

If you go to your storage closet right now, you’ll find several types of corrugated boxes. Depending on their brand, they can be stackable, elongated, round, or square. But how many exact types are there of corrugated boxes? Let’s find out!

The main types of corrugated box designs are:

- Telescopic boxes

- Slotted boxes

- Die-cut boxes

- RSC boxes

- One-piece folder boxes

- BC flute boxes

At its core, a corrugated box is designed to protect your product during shipping. But that doesn’t mean your box has to be boring. There are dozens of different types of corrugated box designs, like single-walled corrugated boxes or liner board facings, each with advantages.

Not sure which type of box is right for your product? Here are six of the most popular types of corrugated boxes:

1. Telescoping Boxes

Telescope half-slotted container boxes are two-piece boxes that nest inside each other. A telescope-design-style container is perfect for products that need to be shipped frequently, as they’re easily bundled or unbundled boxes and take up less storage space than other boxes.

2. Slotted Boxes

Slotted boxes are similar to telescoping boxes but have one piece that fits into the other, like a puzzle. They’re also easy to assemble and take up less storage space, making them ideal for products that need to be shipped frequently.

3. Die-Cut Boxes

Die-cut boxes are custom-made using thick corrugated fiberboard to hold a specific product. They offer a snug fit and can be designed with features like handles or windows to make them even more user-friendly.

4. RSC Boxes

RSC stands for “regular slotted container.” These are the most common corrugated boxes and can be used for various products. RSC boxes are also easy to store and ship, as they can be nested inside each other when not in use.

5. One-Piece Folder Boxes

As the name suggests, one-piece folder boxes fold into place—no tape or glue required. They’re perfect for products that need to be shipped flat, such as documents or artwork.

6. BC Flute Boxes

BC flute is a type of cardboard that’s thick and durable, making it ideal for heavy or delicate items. BC flute boxes can be customized with foam inserts or other cushioning materials to provide extra protection for your product. Also, these corrugated packaging boxes stand the edge crush test because of their triple-walled construction.

6 Particular Types of Corrugated Used in Packaging Boxes

When scrolling through online retailers or visiting your local store, have you ever wondered what kind of box your product came in and why that specific type was chosen?

Underneath a box’s design is a pattern that holds it together and determines how resilient it is for retail packaging. Since this pattern or symmetry is a crucial factor in corrugated boxes, here’s what you must know about it:

1. Single-Phase Corrugated Box

A single-phase corrugated box consists of one layer of fluting sandwiched between two liner boards. This corrugated box is typically used for light products such as clothes, small electronics, or packing material.

2. Single-wall Corrugated Box

A single-wall corrugated box is similar to a single-phase corrugated box, except it has an additional layer of fluting. This additional layer provides more rigidity and protection, making it better suited for retail packaging of heavier products such as books, small appliances, or dishes.

3. Double-Wall Corrugated Box

A double-wall corrugated box has two layers of fluting sandwiched between three liners. This type of box is stronger than single- and double-wall boxes and is typically used for heavier products such as furniture, electronics, or machinery.

4. Triple-Wall Corrugated Box

Triple-walled, stacked corrugated sheets have three layers of fluting sandwiched between four liners. These three stacked corrugated sheets provide maximum protection and are often used for hefty products or products that require extra protection, such as glassware or high-end electronic equipment.

Thanks to the triple-walled construction, such a shipping box can bear the edge crush test.

5. Foil-Coated (MET) Tape

Foil-coated (MET) tape is a double-sided tape with a conductive acrylic adhesive on one side and aluminum foil on the other. The tape creates electrical and thermal conductivity paths between surfaces that would not normally be conductive.

This tape can be used in various applications, such as EMI/RFI shielding, grounding, or double-walled thermal management.

6. Adhesive Transfer Tape

Adhesive transfer tape is a pressure-sensitive adhesive that comes on a release liner. The release liner protects the adhesive until it is ready to be used. Once the release liner is removed, the adhesive can be applied to surfaces such as paper, plastic, metal, or double-wall foam.

When shopping online or in stores, take note of the different box products and consider why that particular type was chosen for the contents inside. Also, an edge crush test will help you decide whether you need a triple-wall corrugated board or a thicker version.

14 Tips to Choose a Corrugated Box Design to Suit Your Brand’s Voice

In today’s competitive marketplace, businesses must have a consistent brand voice across all their marketing materials. Your corrugated packaging is no exception! The design of your boxes can say a lot about your company, so it’s crucial to choose a style that suits your brand voice.

Here are a few things to consider when choosing a box design for your business:

1. The Purpose of the Box

First and foremost, you need to think about the box’s purpose. What will it be used for? Will it be storing fragile items? Shipping products across the country? Displaying items in a retail setting The answers to these questions will help guide the rest of your decisions about the box design.

2. Your Target Audience

Who is your target audience? What age group are they in? What are their interests? What other brands do they love? Answering these questions will help you choose a design that appeals to your target market.

3. The Overall Look and Feel of Your Brand

What is the overall look and feel of your brand? Is it modern and sleek? Rustic and earthy? Classic and timeless? Fun and playful? Again, the answers to these questions will help guide your decision about the design of your corrugated box.

4. The Colors You Want to Use

What colors are associated with your brand? Do you want to use those same colors on your boxes, or are you looking for something different? If you’re going for something different, what color scheme will complement your brand’s colors without clashing with them?

5. The Product itself

When choosing a corrugated box design, you must first consider the product itself. What are the dimensions of the product? Is it fragile and in need of extra protection? Does it have any special packaging requirements? Answering these questions will help you narrow your choices and find a box that best protects your product.

6. The Recipient

The recipient is the second factor to consider when choosing a corrugated box design. Who will be receiving the product? A business? An individual? A family? This question will help you determine what type of box to use.

Say you are shipping a product to a business; you may want to choose a more plain and professional-looking box. On the other hand, if you are shipping a gift to an individual or family, you may want to select a decorated box or special features like handles or ribbons.

Knowing who will receive your shipment will help you choose a functional and aesthetically pleasing package.

7. The Brand’s Message

Your product’s packaging is an extension of your brand. It should reflect your company’s values and communicate the message you want to send to your customers. For example, if you want to communicate that your brand is luxurious, you might choose sleek and elegant packaging.

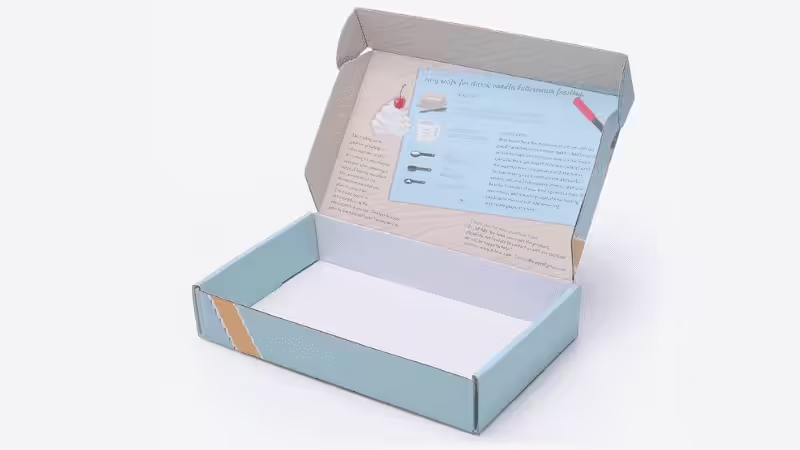

8. Unboxing Experience

In today’s digital age, the unboxing experience is more important than ever. Customers increasingly rely on retailers to provide a positive unboxing experience, with many products being ordered online. This means that the first impression of your corrugated packaging matters now more than ever before.

For example, if you want customers to feel like they’re opening a special present, you might choose festive and fun packaging. Or, if you want customers to feel like they’re opening a high-end product, you might select sleek and minimalist packaging.

9. Sustainability

When choosing a corrugated box design, consider the environmental impact of the materials used. Corrugated boxes are made from paper, which is a renewable resource.

However, the production of paper does require water and energy. To minimize the environmental impact of your packaging, look for corrugated boxes made with recycled paper or recyclable materials.

10. Branding Considerations

Another thing to emphasize when choosing a corrugated packaging design is how it will impact your brand. The packaging you use is an extension of your brand and can influence perceptions of your company. Choose a box design consistent with your brand identity and make a good first impression.

For example, if you sell luxury items, you will want to use packaging that conveys luxury (e.g., clean lines, minimal graphics, etc.).

11. Packaging Cost

Packaging is a crucial aspect of any business, and when you’re targeting a broad customer base, you must crack the best deal. You should ensure that the packaging costs align with your budget and that you are not overspending on packaging materials.

There are a few ways to keep costs down regarding corrugated boxes. One way is to choose a smaller box size and a less expensive printing method, such as digital printing, instead of foil stamping or embossing.

12. Custom Sizes

Using high-quality, custom packaging is a clever move to make your products stand out. Sure, custom box sizes can be more expensive than standard sizes, but they’re worth it if you have an unusual product shape or size.

If you need custom corrugated boxes, make sure to work with a manufacturer that offers this service to get the perfect fit for your product.

13. Printing Options

Luckily, we have many printing options in corrugated packaging to personalize them. When shortlisting box designs for your business, make sure the design is visible and eye-catching.

You also want to ensure that the printing option you choose will be durable. Some printing options include digital printing, Flexo printing, and screen printing.

Digital printing is popular for corrugated boxes because it is versatile and can produce high-quality images. Flexo printing is another popular choice because it is a cost-effective way to print large quantities of boxes. Screen printing is a good choice for simple designs or boxes that will be used for storage.

14. Box Closure Type

The type of closure you choose for your corrugated box should be based on how the box will be used. If the box is used for shipping, you will want to choose a closure that will keep the contents secure during transit. Some common closure types are tuck flaps, glued trays, folding cartons, and RSCs.

Tuck flaps are commonly used for small boxes that do not need to hold much weight. Glued trays are good for packages holding more weight or for shipping fragile items.

Folding cartons are usually used for larger items, such as appliances. RSCs (Regular Slotted Containers) are the most common type of closure and can be used for various purposes.

Choosing the right corrugated box design is vital for any business owner. There are many factors to consider, but if you keep your brand voice in mind, you’ll be sure to choose a design that suits your company perfectly!

7 Top Benefits of Using Corrugated Boxes in Your Business

At first glance, corrugated boxes may not seem like they would offer many benefits for your business. However, these boxes are versatile, affordable, and eco-friendly, making them an excellent choice for businesses of all sizes.

Keep reading to learn about the benefits of using corrugated packaging for your business.

1. Versatility

Corrugated boxes come in various sizes, shapes, and designs to suit any need. No matter what you’re looking to ship, there’s a corrugated box that’s perfect for the job. Furthermore, these boxes can be customized with your company’s logo or other branding elements to give your products a professional look.

2. Affordability

One of the best things about corrugated boxes is that they’re affordable, especially when you compare them to other shipping options like wood crates or metal containers. You can find these boxes at any office supply or packaging store, which makes them easy to get your hands on when you need them.

3. Eco-Friendliness

Corrugated boxes are made from recycled materials, making them an eco-friendly option for businesses looking to reduce their environmental impact. These boxes can be recycled again after they’ve been used, which further reduces their environmental footprint.

Furthermore, using recycled materials helps to save trees and other resources that would otherwise be used to create new packaging materials.

4. Ability to Protect Your Products

When you use corrugated packaging to ship your products, you can rest assured that they will arrive safely and soundly at their destination. These boxes are designed to protect your items from damage during transit, meaning you won’t have to deal with angry customers or replacement costs.

5. Lightweight and Stackable

Another great benefit of using corrugated packaging is that it’s very lightweight, which keeps shipping costs down. This is especially beneficial for businesses that ship large quantities of products regularly. The lighter weight also makes these boxes easier to handle and less likely to cause injuries while loaded or unloaded.

6. Easy Assembly

Corrugated boxes are straightforward to put together—all you need is a bit of tape, and voila! This makes them ideal for businesses that don’t have much time or manpower to spend packaging their products.

Furthermore, these boxes can be easily disassembled and stored flat until they’re needed again, saving you time and effort in the long run.

7. Professional Look

When you use corkboard shipping boxes, you give off an air of professionalism. Your potential clients will subliminally notice this, making them want to do business with you even more than if you were using plain old cardboard boxes.

As we mentioned, you can add branding elements like logos or company colors to make them stand out.

7 Tips for Designing Personalized Corrugated Boxes

A few weeks ago, we wrote a blog post about the importance of using personalized corrugated boxes for your business. We discussed how they can help you build brand recognition and customer loyalty. Today, we want to follow up with a post about how to design personalized corrugated boxes that will make your brand shine.

1. Keep it Simple

When it comes to designing your box, less is more. You want your package to be eye-catching, but you don’t want to overwhelm your customers with too much information or too many graphics. Stick to a simple color scheme and a handful of well-placed graphics for your shipping boxes to make them stand out!

2. Make it Memorable

Your goal is to make sure your box is memorable—in a good way! That means choosing a color scheme and design that represents your brand. If your brand is fun and playful, go for bright colors and fun graphics. If your brand is more serious, opt for a more subdued color palette and clean lines.

3. Use High-Quality Imagery

Your customers should be able to tell, at a glance, what’s inside your box. That’s why it’s important to use high-quality images in your box design. Product photos are always a good choice, but you can use lifestyle photos or simple graphics. Just make sure that the imagery is clear and easy to see.

4. Keep Your Text Readable

In addition to using high-quality visuals, you must ensure that your text is easy to read. Use a simple font that will be easy for customers to scan. And don’t forget to leave plenty of white space around your text so that it’s easy on the eyes.

5. Make an Impact with Color

Color is one of the most powerful tools in your box design toolkit. The right colors can make your box pop, so choose wisely! If you’re not sure where to start, try using 2-3 colors that complement each other well. And remember, less is usually more when it comes to color usage.

6. Consider Die Cuts

If you want your box design to stand out from the crowd, consider die cuts! Die cuts are special shapes that are cut into the cardboard itself.

They can be used for everything from windows (so customers can see what’s inside the box) to handles (for easy carrying). Die cuts are a great way to add extra interest and intrigue to your design.

7. Think Outside the Box…Literally

Don’t be afraid to think outside the literal box when it comes to your design! There are no rules for the design of shipping boxes, so let your creativity shine through.

You might even consider using something other than cardboard for your boxes, like wood or plastic, for an extra-unique look. Whatever you do, make sure your final design reflects your brand identity memorably.

Conclusion

Corrugated shipping boxes are an essential part of the packaging industry, and their popularity is well-deserved. They are strong and lightweight, and they can be customized to fit any product. Thanks to their resilience, corrugated boxes are an excellent choice for businesses and consumers.

From protecting your products to promoting your brand, corrugated boxes can do it all. So when you’re looking for a way to package your products, remember that corrugated boxes offer strength, durability, and flexibility—everything you need to ensure safe delivery.

Want the Most Eye-Catching Product Packaging? Granted!

Welcome to Packoi Printing, where your custom packaging needs are met the best!

If you need corrugated boxes for your business, we’ll make custom boxes that promote your brand’s personality and are eco-friendly.

We use recycled materials and build each box with sustainability in mind. Plus, our team of skilled craftsmen will work with you to create a one-of-a-kind design that perfectly reflects your brand.

We believe every business deserves a unique packaging solution that meets their needs. So whether you’re looking for durability, style, or eco-friendly options, we’ve got you covered.

Take a look around our shop and see for yourself how we can help your business stand out from the rest. Contact us today!