Last Updated on November 20, 2023 by Packoi Team

While there are many types of boxes to choose from, you’ll notice that the most common option is cardboard shipping boxes.

In this article, you’ll learn about the basics of corrugated cardboard boxes and the qualities you need to look for in choosing the best shipping boxes.

What Is a Shipping Box?

A shipping box is a type of cardboard box that the packaging industry manufactures in millions of tons a year. Sometimes called a corrugated box, these containers are versatile and cost-efficient, so they have become a favorite packaging solution for most businesses.

Shipping boxes come in different forms.

1. RSC

RSC or regular slotted container boxes, have flaps at the top and bottom that meet in the middle to close. It’s also known as a corrugated box because that’s the standard material to make it sturdy and durable.

Use corrugated boxes as shipping boxes meant for fragile products. Use double-corrugated material to provide more protection. There are many types of corrugated paper, most of which are strong and suitable for storage boxes to transport.

2. Tuck-top Boxes

This type of box has a flap that covers the top of the box and extends to the side so it can be tucked to secure and close. The best example is mailer boxes. These shipping boxes are sometimes called cardboard boxes. It has a preference for using cardboard as opposed to corrugated material.

3. Custom Boxes

The thing about corrugated boxes is that you can create them in any shape or form. This is where all the other types of boxes are categorized. But this isn’t just for corrugated boxes.

You can use other materials aside from corrugated cardboard. There’s kraft paper and even wood. These can also be used to create custom-made boxes for shipping packages.

2 Types of Shipping Box Materials

There are two prominent shipping boxes used by businesses today.

Corrugated boxes are made of 3-layer corrugated cardboard material, while cardboard boxes are made of flat paperboard material.

That may seem like two similar things: corrugated cardboard and cardboard, but there are differences that you should know so you can choose the right material to use.

1. Cardboard Boxes

Corrugated cardboard is not the same material used to make cardboard boxes.

Cardboard boxes use a paperboard made of firm paper-pulp material to create the walls and flaps of the box. It’s quite sturdy, even if it’s lightweight.

But cardboard shipping boxes are best for small and lightweight packages only.

If you need to ship out heavier objects, this might not be the right material to use.

2. Corrugated Boxes

Corrugated cardboard boxes use a material called corrugated fiberboard. This material has 3 layers: 2 flat and 1 rippled paperboard. These three are glued together, with the rippled paperboard in the middle being sandwiched by the flat boards.

This is what makes corrugated boxes very durable. The three layers of a corrugated box provide triple the protection compared to that of a cardboard box.

So if you want to ship out heavier or fragile objects, use corrugated boxes. You can learn more about corrugated packaging on our website.

2 Measurements of Strength in Shipping Boxes

When you’re choosing shipping boxes, it’s important to note the strength of each box. These boxes are handled and stacked on top of each other during transit. You want to ensure your box won’t easily be damaged in the process.

Corrugated cardboard is the stronger material. So if you’re shipping out bigger objects requiring extra protection, your best option is to use a corrugated shipping box.

But even so, you need to ensure the box you’ll use passes 2 different types of strength tests.

1. Burst Strength

The burst strength uses the Mullen test, where hydraulic pressure is applied to boxes until their board gives away. The most common rating for burst strength is #200. Shipping boxes with this rating mean they can withstand 200 psi before rupturing.

That means even with the typical rough treatment in high-speed sorting areas, the box won’t rupture.

2. ECT (Edge Crush Test)

On the other hand, the ECT, or edge crush test, tests a box’s compression strength. Another term for this is stacking strength. It measures the stiffness of a board when it stands. It rates the board based on how much downward force it’ll require to crush it.

The most common rating is 32 ECT. It means shipping boxes can withstand 32 psi of vertical compression. The higher the ECT, the heavier the boxes that can be stacked on it.

What Size Shipping Box Do You Need?

Once you’ve figured out the box’s strength, it’s time to consider the different box dimensions you can use.

While shipping boxes can be created in all shapes and sizes, you still have to consider the standard dimensions set by shipping companies. If you don’t comply, you’ll pay higher shipping costs.

So do your research before you finalize your choice for the box style. In the meantime, here are the different box sizes and shapes that you can use.

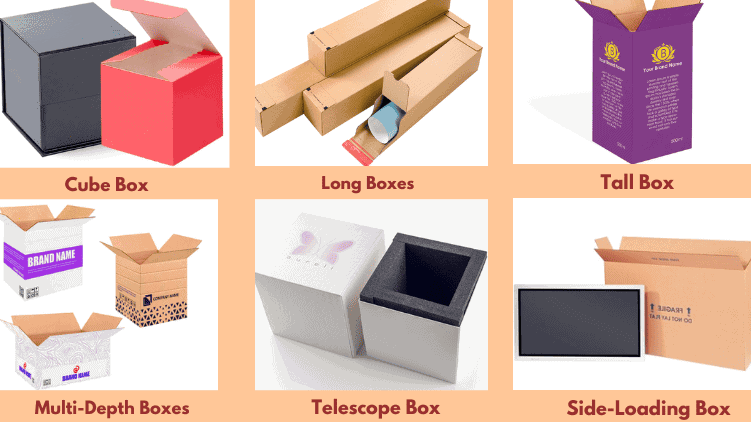

- Cube boxes are square-shaped traveling boxes. They have the same measurement on all edges.

- Long boxes are traveling boxes that are longer horizontally. Their length is greater than the measurement of their width and height.

- Tall boxes are traveling boxes that have to be kept in a vertical position. The height is greater in measurement compared to the length and width.

- Multi-depth boxes are traveling boxes that are designed for flexibility. It allows you to change the height of the box. The width and length stay the same.

- Telescope boxes are traveling boxes that have separate top and bottom parts. This allows the box to be adjusted according to the length of the item being shipped.

- Side-loading boxes are thin traveling boxes with an opening at the side instead of the top. This makes it look like the box is lying down.

5 Benefits of Using Eco-Friendly Boxes for Shipping Packages

Boxes are the most common choice for shipping packages. This is the most practical and economical way to ensure that goods arrive at their destination in perfect condition.

But of all the box styles and materials you can choose from, why would you choose an eco-friendly shipping box?

There are five reasons why this is a beneficial choice.

1. Provides Protection

Shipping boxes, specifically corrugated boxes, are very sturdy. Corrugated boxes with three layers of design ensure that whatever is inside the box is fully protected from the typical handling and jostling that happens during shipment.

You can trust that shipping storage boxes are enough to protect your product. Of course, if the product is fragile, you have to add cushioning materials to keep it from moving around inside the box.

2. Carries Multiple Packages

Shipping packages together is more economical than doing it individually. The good thing about shipping boxes is that you can put several items in them. You can stack them together so they don’t move around.

Just remember to ensure that the boxes inside won’t move or hit each other. Put fillers inside to keep boxes from hitting each other.

3. Creates Brand Awareness

Since the material used to create shipping boxes is versatile, you can easily print brand elements in it so people will recognize your brand.

Print your brand logo and name on it. You can print some of that on the box surface if you have a specific design. That way, people will know that your item is inside the box.

4. Eco-Friendly Qualities

Corrugated boxes are eco-friendly because they are made of paper from a renewable source.

But when it comes to being eco-friendly, make sure you’re thorough about it. If you have to print something on the box, use eco-friendly ink. The same is true for the packing tape and labels. These have to be eco-friendly as well.

5. Costs Less Than Alternatives

Compared to other options, a shipping box will cost you less. You can order them in bulk, lowering the price per piece.

Since the material is lightweight, you don’t have to worry about high shipping costs. Do your research about the standard rules of the shipping company so you can choose the right shape, size, and style of the box.

Discover the Perfect Solution for Your Business with Packoi

Using shipping boxes is a great way to protect your items and make sure they get to their destination without damage. But it’s important to choose the right box to fit the package’s needs. Whether it is corrugated boxes, cardboard boxes, or other materials, we can customize them for you.

If you want to know your options, Packoi Printing is here to help. We can show you the different possibilities regarding box dimensions and designs.

Give us a call so we can discuss your ideas. We’ll get back to you with a fair quote immediately.