From the moment the customer sees your package to the opening and removal of the fillers or cushioning materials, the box insert is the platform on which your product will be revealed to the customer.

That role makes it important enough to choose the proper setup for your custom box insert.

In this article, you’ll get a deeper insight into box inserts and how you can find the right one for your product and custom packaging. You’ll get a list of typical products that require these inserts, plus suggestions on what insert would be perfect for each of them.

Defining Box Inserts

Box inserts keep items in place and even allow you to ship multiple products at once. This packaging insert is a useful tool that presents your product in the best possible light to your customers.

When done correctly, it allows you to impress customers with the unboxing of your products. It gives you the chance to display your creativity and elevate the value of your brand.

These inserts come in different forms and materials – but they shouldn’t be confused with another type of packaging insert.

Promotional Inserts

Promotional inserts, as the name suggests, are marketing materials or tools that promote your brand and other product lines. Examples of these packaging inserts include discount cards, thank-you notes, and even product samples.

These promotional inserts are placed inside the product box along with the purchased product. Sometimes, these are meant to offer information to help the customer use the product better.

Other times, these promotional inserts are given to push a different product in hopes of increasing its sales.

Unlike box inserts that are meant to be functional, promotional inserts are there to improve a customer’s perception of your business.

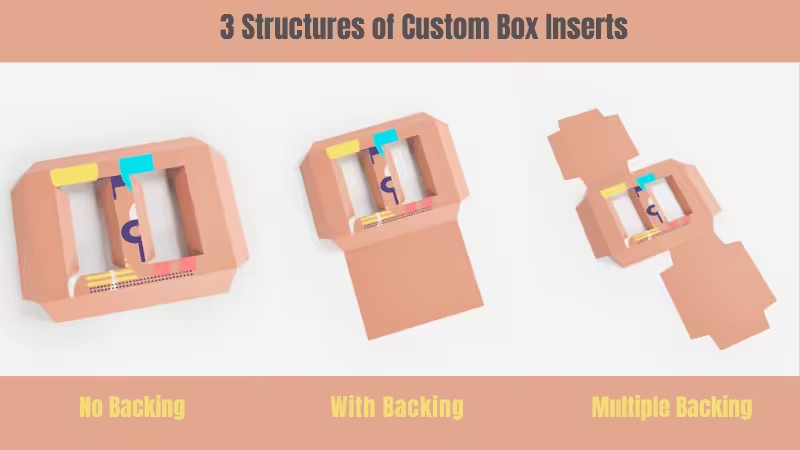

3 Structures of Custom Box Inserts

The structure of your custom box inserts influences their ability to protect and keep your products in place. You need to choose the correct insert options based on the size, weight, and shape of the product.

Here are 3 structures that you can use as custom inserts.

1. No Backing

These are box inserts that allow the product to touch the bottom of the custom boxes. It’s a tray with holes for the products and nothing at the bottom.

There’s no elevation provided, so it’s important to use this for products of the same size that are big enough to rest on the box without falling off.

2. With Backing

These custom box inserts are ideal for smaller items that require elevation to avoid movement while the box is in transit. The product tray has holes but is provided with extra material that folds under the product for a snug fit.

3. Multiple Backing

This is an option when your custom boxes are carrying multiple products in different sizes. The extra materials attached to the product tray provide different levels of elevation to give the items a more organized look.

It also allows you to fix the elevation so each product gets a snug fit.

These can easily be recyclable materials, making them a sustainable option that’s both versatile and functional.

2 Common Materials for Custom Box Insert

The insert material is crucial in making sure that a product reaches the customer in good condition. According to reports, 11% of shipped products reach the distribution center with some form of damage.

Primarily, the task of protecting a product lies in the outer packaging. However, it’s proven that custom inserts significantly increase the odds in favor of the product during shipment.

This is why you have to be careful when choosing the material for your custom box inserts. Here are the 2 common materials that you can choose from.

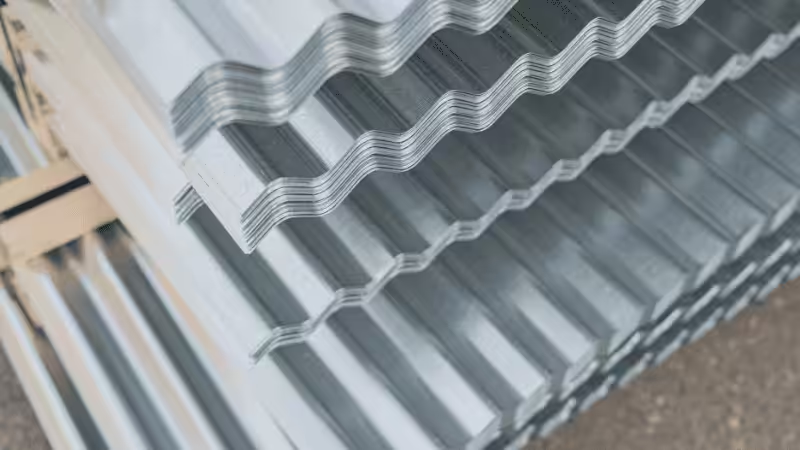

1. Corrugated Cardboard Material

This is a popular option, specifically for delicate products. Corrugated cardboard inserts have 2 layers or more of paperboard material.

This material is usually a combination of a flat board and a fluted (curved) board. Depending on the fragile nature of a product, corrugated boxes can be as thick as 7 layers (triple wall board).

While there are many types used for product boxes, corrugated box inserts only come in 2 types:

- E-flute corrugated cardboard inserts are the most common option. These have a flute thickness of 1.2mm to 2mm.

- B-flute corrugated cardboard inserts are ideal for more extensive and heavier products because they are thicker. The flute ranges from 2.55mm to 3mm.

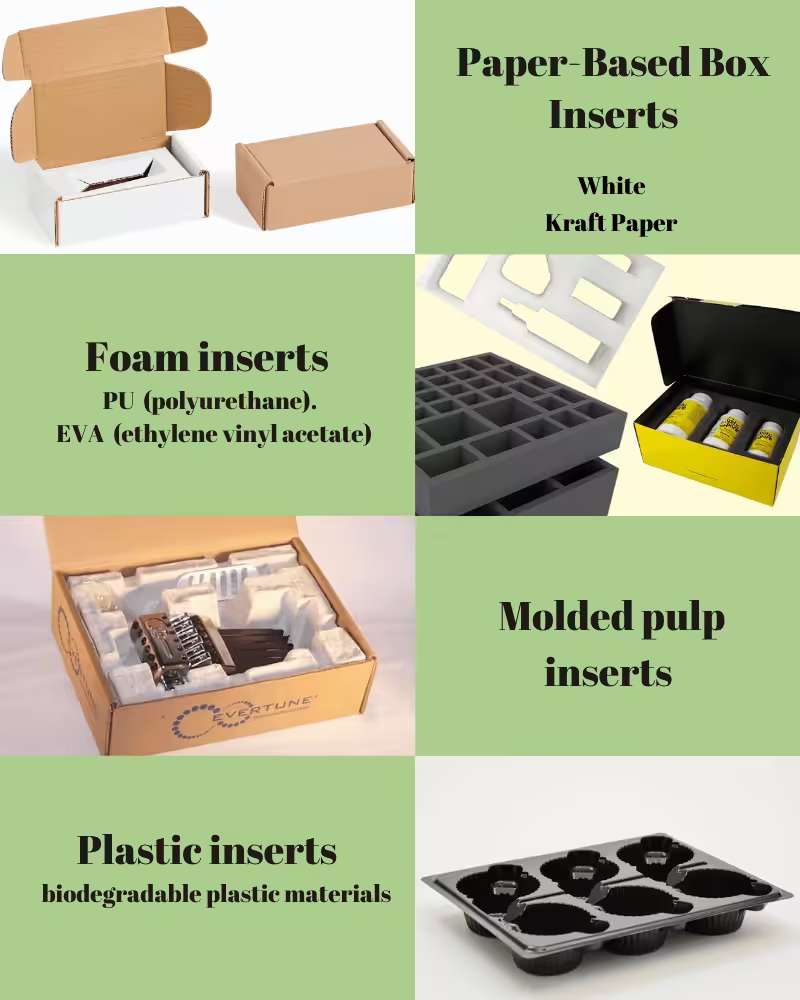

2. Non-Corrugated Material

Everything else that’s not corrugated is grouped into one category: the non-corrugated. These are ideal for lightweight products. This includes the following:

- Paper-based materials like white and kraft paper can be used as cavities, die-cut trays, or molded inserts. These white or kraft paper inserts should have a standard thickness of 300 to 400 gsm to make them sturdy enough to hold products.

- Foam inserts come in various forms. One is PU foam inserts (polyurethane). It’s cost-efficient and great for thermal insulation. It’s also sustainable because it doesn’t need a lot of energy to produce. Another option is EVA foam inserts (ethylene vinyl acetate). These are sturdier and denser materials, like yoga mats. They’re not biodegradable, but they can be recycled, so they pass as a sustainable option for foam inserts.

- Molded pulp inserts are made of recycled materials and formed to fit the shape of the products. These are often a combination of paper and cardboard materials.

- Plastic inserts can be molded into any shape that the product requires. It can be a very thin tray or a more rigid one. You have to be careful with the design because it might make the package heavier if the plastic is dense. If you worry about sustainability, there are biodegradable plastic materials that you can use.

Other Considerations for Custom Box Inserts

When you’re planning the custom packaging inserts, there are other things that you need to consider before you finalize your design.

These are essential factors that can affect the overall look of your product packaging. These will also help you identify the right material that suits your packaging needs.

1. Color Printing

Most custom box inserts come in plain, solid colors. But there’s no rule preventing you from being creative about it. Plain outer packaging can be combined with colorful and creatively designed inner packaging.

When you’re discussing colors with the packaging supplier, there are two ways that you can go about it.

- CMYK refers to the widely used color system that combines cyan, magenta, yellow, and black. You can use this option if you’re not very particular with the color accuracy of your inserts.

- Pantone represents more accurate colors and can be more costly than CMYK. But if you’re particular with your brand colors, this is the right option for you to use.

2. Coating

The coating of the packaging insert is not as important as the outer packaging. But to create an impression with your packaging, think about the coating as well.

If you prefer to add promotional inserts, you should consider the coating to ensure that the information you provide is visually appealing.

There are two options for the coating.

- Varnish refers to the water-based coating applied to paper-based materials. While it’s more eco-friendly, it doesn’t offer as much protection.

- Lamination refers to the layer of plastic coating that protects your designs from damage. It’s not as environmentally friendly as varnish, but some companies offer bio-based lamination.

3. Finish

Again, this is ideal for promotional inserts more than box inserts. It shows customers that you pay attention to the details. A finish gives your custom box inserts an excellent finish. You have 4 options to choose from.

- A matte finish gives a smooth and softer look.

- The gloss finish looks shiny and tends to leave fingerprint marks, which could make the insert look dirty.

- The satin finish is like a hybrid of the matte and gloss finishes. It’s not too shiny and looks smoother.

- The Soft Touch finish looks like a matte finish but feels like velvet when you touch it.

3 Vital Qualities of Custom Box Inserts

To enjoy the full benefits of custom box inserts, you need to ensure that they possess the right qualities. While there’s no restriction when it comes to being creative with your custom inserts, there are 3 must-haves that you cannot go without.

1. Protection

Did you know that return shipments cost a total of $32 billion in just one holiday season? 20% to 30% of that is caused by product damage. While that seems like a massive loss for businesses, that’s not the worst part.

Every time a customer receives a damaged product, it puts a dent in your brand’s reputation. It negatively affects their customer satisfaction and can even dissuade them from ordering from you again.

They might also badmouth you and tell their family and friends not to order from you.

How can you avoid this? Through custom packaging inserts. While the packaging industry puts a lot of importance on the outer packaging, the inner packaging also plays a role in protecting a product from damage. Packaging inserts are a part of this inner protection.

2. Aesthetic Appeal

The insert plays a role in the product reveal. It allows you to be creative in the way you present your products to customers. This is why you need to pay attention to the aesthetic appeal that the custom inserts will provide.

If your target market sees how creative you can be, even with the inserts, they’ll appreciate how much thought and effort you put into making them happy. That’s one way to strengthen customer loyalty.

3. Brand Promotion

The brand image is another thing that packaging inserts can help with. As mentioned, it can help with brand loyalty. But it can do more.

Choose the right design that will represent your brand. This is how you strengthen brand recognition.

10 Product Types and the Ideal Custom Inserts for Each

Now that you have a better understanding of custom box inserts, it’s time to get inspiration so you can apply what you know. The application of custom box inserts will depend on the product that they’ll carry.

Here are 10 product types and our suggested box inserts that fit their specific needs.

1. Fragile Products

If you’re selling and shipping fragile products like glass figurines, glasses, light fixtures, and other breakable decor, you need soft box inserts that are shock-absorbent.

You also need the insert to have a snug fit so it doesn’t move while in transit. This would require you to use molded pulp or foam inserts.

2. Small Items (e.g. Jewelry)

For small products like jewelry, you want the box inserts to have compartments or slots instead. Due to the small size, it’ll be harder to mold the insert into the exact shape of the product.

You’re better off providing compartments that are wrapped in fabric so the delicate products will be protected even from each other. Using luxurious fabric materials like velvet would fit jewelry products because of the elegance and sophistication that it brings.

3. Electronic Devices

Custom box inserts for electronic devices need to be crafted to fit the product and all the accessories that are packaged with it. This means you’ll need different types of compartments. You might need a mold for the actual product and slots to fit the other accessories.

Use corrugated inserts to provide protection for the items and give them a snug fit. Present all the items in such a way that they’re all visible once the customer opens the box.

4. Cosmetics and Grooming Kits

This is another product type that requires different box inserts. For cosmetics and grooming kits, you want to give all the products their own space.

You also want to ensure they fit snugly so they won’t dislodge while in transit. Using paperboard inserts with die-cuts could work. Or you can use foam inserts.

5. Bottled Products (e.g. Perfume)

These can also be considered fragile products, but the bottles are usually thicker and more robust. But still, you need box inserts that provide a snug fit so the bottles won’t break. Among the options you can use are corrugated inserts with custom cavities.

Or inserts with partitions so the bottles are upright. For luxurious perfumes and colognes, you can use a velvet fabric insert that’s molded to fit the product.

6. Stationery and Books

These are not fragile, but you still need box inserts that can keep the items organized. If you’re shipping books and other stationery items, make sure the inserts have slots or compartments to keep everything upright.

A cardboard insert might do the trick. Add your branding for marketing purposes.

7. Food and Consumable Goods

Since these products are consumables, they require a bit of thought so the integrity of the food items won’t be compromised. Get to know the specific needs of the product.

If there’s a lot, you might need layers to fit all the assortment of products. You can use cardboard box inserts or even plastic inserts as your options.

8. Shoes and Bags

Most shoes and bags are shipped without box inserts. But if you want to stay ahead of the competition, do something that others aren’t. For instance, use corrugated material that’s shaped like a shoe.

A fabric insert can be used for the bags. Doing this might seem unnecessary, but if it elevates the value of your product and your brand, it’ll be worth it.

9. Fashion and Accessories

Using box inserts for clothes is a practice that luxurious brands use. But you can also do it if you wish to elevate the value of your brand.

Use inserts with foldable sections that’ll allow you to put the fashion item without wrinkling or creasing it. Use recyclable materials for added appeal.

10. Gift Sets

These box inserts would have to accommodate different types of products; sometimes, they’re not even in the same category.

It’s probably best to use accordion inserts here so the slots and compartments are adjustable. Make sure each product in the gift set is visible to create a great unboxing experience for the customer.

Conclusion

Custom box inserts play a crucial role in protecting products, enhancing presentation, and reinforcing brand identity. By choosing the right insert structure and material, you can ensure a secure and visually appealing unboxing experience for your customers.

Whether your product is fragile, compact, or part of a premium gift set, selecting the right insert will elevate your packaging and boost customer satisfaction.

If you’re ready to create high-quality, sustainable box inserts, Packoi Printing is here to guide you through the process.

Are You Ready to Custom Box Insert for Your Product? Packoi Printing Is Ready to Assist.

Using the correct insert for your product gives you a chance to impress your customers and bring growth and higher sales to your brand. Make sure you do thorough research on your options so you can choose the perfect insert for the specific needs of your product.

If you need help finding sustainable box inserts, Packoi Printing is here to help you. We can guide you and inform you of the options that you can explore.

Contact us today so we can talk about your specific product packaging requirements. You’ll get a fair quote from us in no time.