Last Updated on August 29, 2025 by Packoi Team

Your product is ready for market, but you’re faced with a critical choice: how do you package it to protect it, enhance its appeal, and communicate your brand’s values, all while keeping costs low? Traditional shipping boxes are bulky, and plastic is no longer a viable option.

For lightweight items, from cosmetics to gourmet foods, custom folding cartons offer a powerful solution. They’re not just a box; they’re a brand experience. This guide will walk you through everything you need to know about choosing and designing the perfect folding carton to elevate your brand.

The Anatomy of a Folding Carton: Types & Features

Paperboard cartons, folding cartons, and paperboard boxes are all common synonyms for carton packaging. Throughout history, folding cartons have been the most popular brand packaging option and remain one of the most popular today, as they have many benefits compared to corrugated boxes.

As a result of increased eco-awareness, businesses have chosen paper carton packaging to represent themselves as an ethical brand, as they are a more sustainable means of meeting consumer demands.

When you choose folding carton packaging, the design possibilities are vast. Understanding the most popular styles and their key features is the first step to finding the perfect fit for your product.

Standard Tuck End Boxes

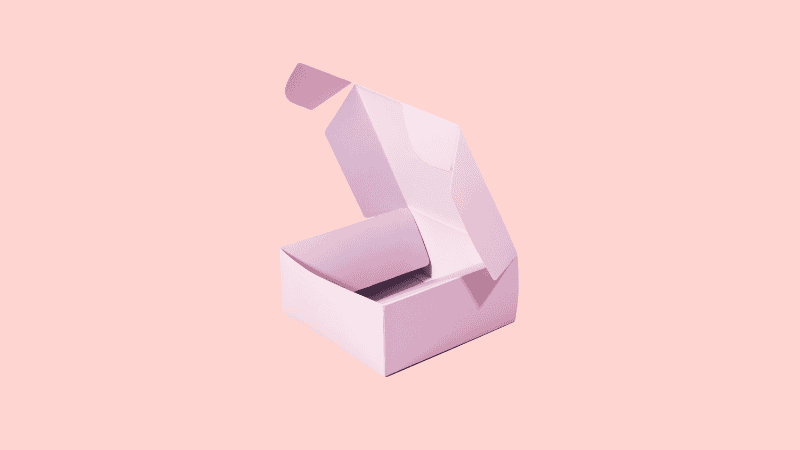

These are the most common and versatile folding cartons. They arrive flat and are easy to assemble.

- Reverse Tuck End (RTE): This design has tuck flaps that close on opposite sides of the box. They are cost-effective and are great for lightweight items.

- Straight Tuck End (STE): This style has both tuck flaps on the same side of the box, giving it a cleaner, more premium look. They are often used for cosmetics and retail products.

Auto-Bottom & Crash-Bottom Boxes

These styles are built for efficiency and durability, especially for heavier items.

- Lock-Bottom Boxes: Also known as “1-2-3 bottom boxes,” these have a secure, interlocking bottom that can be assembled quickly for heavier products.

- Crash-Bottom Boxes: These come with the bottom pre-glued, allowing them to snap into place instantly. This is the fastest option for high-speed automated packing.

Specialty Carton Styles

For products that need to be displayed or have unique shapes, these options stand out.

- Top-Tuck Boxes: Similar to a traditional cake box, these are perfect for displaying apparel or multiple small items.

- Five-Panel Hanger Tab Boxes: These feature an extended panel with a hanger tab, making them ideal for displaying lightweight products on a retail hook.

Boxes come in different varieties, but they also share some common customization features. You can add extra features to any folding carton to improve function and aesthetics.

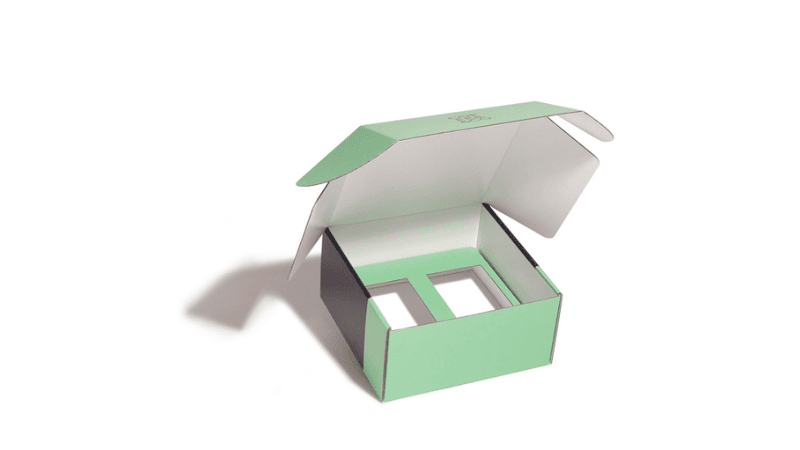

- Adding Inserts: Inserts are custom-fit paperboard pieces that hold products in place, protecting fragile items and organizing multiple components within the box.

- Custom Cutouts: A cutout is a window or a custom-shaped opening that reveals the product inside, giving customers a direct view of what they are buying.

- Thumb Tabs: These small, semi-circular cuts make opening the box easy and intuitive for the customer.

After knowing this basic information about folding carton boxes, let’s delve into the world of folding cartons. Explore how to choose the right carton packaging for your product, the various types of carton packaging boxes, and their applications!

The Most Popular Designs for Folding Carton Packaging Boxes

Here are a few of the most prevalent tuck-top boxes on the market:

1. Boxes with a Reverse Tuck End (RTE)

Boxes with a reverse tuck end (RTE) have panels that close the box on opposite sides. One panel on the front section and the other on the back of the box close it. These customizable folding carton boxes are easy to put together, cheap, and shipping-friendly.

Most of the time, a slit-lock tab is there on the carton packaging to close the ends of reverse tuck end boxes. They are ideal for lightweight items, but they cannot transport heavy objects.

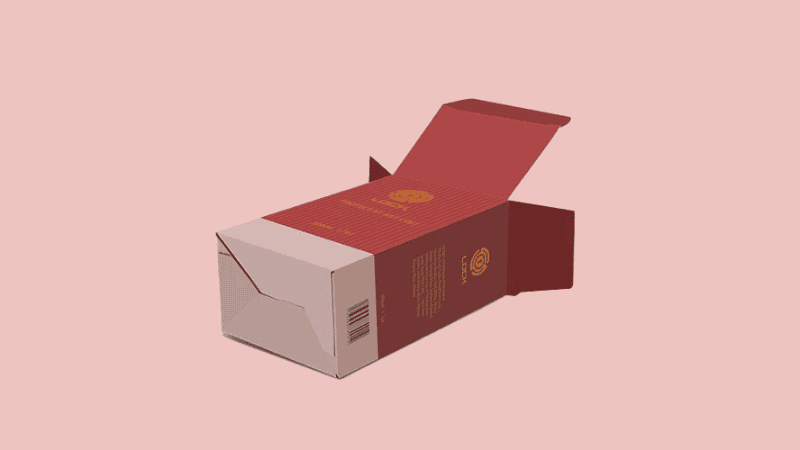

2. A straight Tuck End (STE)

A straight tuck end (STE) gives the entire box a more sophisticated and cleaner look, as there are no raw edges. These folding carton boxes are simple to assemble, flat-packable, and ideal for lightweight objects. In addition, they often utilize a slit-lock for safe closure.

Most of the time, straight-tuck-end boxes cost more than reverse-tuck-end boxes because there are fewer boxes per sheet of paperboard.

3. Lock the Bottom Boxes

Lock-bottom boxes, which are also sometimes called “1-2-3 bottom boxes”, are made for heavier items. Typically, this type of carton packaging has a tuck-top closure. Like the preceding types, these box cartons can be stored flat since they feature a flat bottom, flat-bottomed lock-bottom boxes that stack, and look nicer on shelves.

Numerous food products are packaged in various types of box cartons. One of the drawbacks is that the cost of purchasing them is typically higher than the cost of purchasing other carton box options.

4. Crash-Bottom Boxes

Crash-bottom boxes come pre-glued on the bottom for increased durability. Other names for these boxes are auto-lock bottom boxes. They come with a bottom that can be secured in place with a single click.

Auto-locking bottom boxes can also be stored flat and loaded rapidly. Crash-bottom boxes are typically more expensive because of the folding carton manufacturer‘s additional step of gluing the bottom.

5. Top-Tuck Boxes

Top-tuck boxes are what you might consider a cake box, although they aren’t limited to pastries. These boxes are an innovative way to display apparel or several small goods.

The longer hanger panel that extends from the back panel is the single feature that distinguishes the five-panel hanger tab boxes from the reverse tuck end boxes. This is one of the obvious differences between the two types of containers.

These provide a straightforward method for displaying lightweight products in retail settings. To provide customers with a better idea of your product. Five-panel hanger tab boxes can be easily modified to include cutouts.

Your head may be spinning, but keep going. Let’s shift gears and consider a few popular characteristics you might wish to include in your folding carton boxes.

A Few Popular Characteristics of Folding Carton Boxes

- Adding Inserts: An insert is a folded or sometimes bonded piece of paperboard that fits inside your box to secure loose things. This is a great tool if you are shipping fragile things. Or many items that you wish to keep from moving around inside the carton. Custom inserts are compatible with any form of folding carton. They are easily modifiable to accommodate any randomly shaped item you wish to secure.

- Custom Cutouts: This involves removing a portion of the paperboard to reveal the contents. Custom cuts can easily be made in any shape, allowing them to represent your business.

- Thumb Tabs: Tiny circular cuts are made in the main panel of the carton packaging to make it as easy as pie to open the box. Such boxes are commonly known as “Thumb Tabs.”

Now that the types of folding carton packaging boxes are explained, let’s move on to the next step.

Considerations for the Design of Carton Packaging Boxes

When you consider carton packaging box design, you probably think of the fun aspects first.

Which hues should I use? What place should I use for my logo? But first, you must address a few practical design considerations. The choice of folding carton material, the thickness of the paperboard, and the associated cost are three of the most important aspects to take into consideration. Let’s hop in.

Materials Selection for Carton Boxes

When it comes to the construction of your carton boxes, one of the first considerations you’ll need to make is the material to use. You should make this choice before getting in touch with a carton maker.

The most typical materials used to make carton boxes are listed below:

1. Solid-bleached sulfate (SBS)

SBS is made from chemically bleached pulp. It is a medium-density board with a coated top surface and, occasionally, a coated reverse side as well. Internally and externally, it has great printing properties. Graphics of the highest quality will appear crisp on this material.

SBS is also hygienic, has no odor or flavor, and is appropriate for food contact. Because of this, SBS is a popular carton packaging option for products like chocolates, cigarettes, and perfumes. Additionally, it is recyclable and reasonably priced.

2. The Clay Coated News Board (CCNB)

Compared to the SBS board, the Clay Coated News Back (CCNB) board is less rigid. This carton box has a grayish-brown tint on one side and a glossy finish on the other. Although CCNB is less expensive than SBS, it has a lot of disadvantages due to the fact that it is not a pure white hue like an SBS board. You must forgo some graphic quality because it doesn’t print as well.

When it comes to color, remember to talk to your manufacturer about the differences between RGB, CMYK, and Pantone. CCNB can take in water. So, the carton packaging needs to be in a dry place at all times. But CCNB could be a good option if you want to make cheap folded cartons with recycled materials in mind.

3. Coated Unbleached Kraft (SUS or CUK) or Natural Kraft

This product is made completely of recyclable materials. A food-safe polyethylene resin is included with the CUK. Kraft paper box is appropriate for carton packing of heavy beverages since it is strong, durable, and rip-resistant.

Thickness of Folding Carton Paperboard

Next, examine the thickness of the board (the caliper).

Paperboard is available in a variety of thicknesses, so you will need to choose which is optimal for your product.

It must be capable of supporting the weight of your product, but you must also consider the assembly procedure. You do not wish to squander money and time on an excessively thick board.

So that you may get a sense of how thick a standard paperboard box is, typical caliper ranges for items like cereal boxes and macaroni and cheese boxes are between 016 and 018. A counter display may employ a more durable 0.024″ thick board.

Price Considerations Regarding Carton Boxes

Obviously, don’t neglect the bottom line while constructing your carton boxes.

Custom boxes typically cost less than you might expect. However, this is not always the case. Take into account both the materials’ cost and the production process’s effectiveness. And sometimes, spending a little extra is worthwhile.

Think about whether you want to use offset or digital printing. Offset printing is pretty common as the go-to option for bulk and wholesale custom packaging. But it is not ideal for all businesses.

Your option may be slightly more costly, but if it fits within your budget, it may be worthwhile to splurge. There are more graphic and color options, resulting in a more upscale appearance.

Consider the scalability of any options you select as a further consideration. The printing process often becomes less expensive as you place more orders. Consequently, you could want to make one huge order as opposed to multiple smaller ones.

Also, keep in mind the adage that time is money. You should ensure that your cartons are easy to fill with your product. An intricate carton may look cool. But if it is difficult to place the product inside, it is likely not worth it.

10 Advantages of Carton Packaging

Here are some reasons why using cartons is a good idea. The most popular type of paperboard packaging today is corrugated cardboard. Also used to make the corrugated boxes we all know and love.

There is no shortage of eye-catching product packaging with high shelf appeal on store shelves, along with a pretty decent shelf life. The majority of these items are sold in carton packaging, the most eco-friendly packaging option available.

1. Light But Solid

Since corrugated cardboard boxes are hollow and can therefore be packed with fewer, heavier materials, it makes for a lightweight and rigid box. As a volume comparison, it weighs only a fifth to a quarter as much as a wooden box of the same size.

This lighter product packaging is commonly a part of retail packaging, cereal boxes, telescope boxes, iPhone boxes, and various other boxes.

2. Small in Size

The corrugated packaging box may be flattened when not in use, making it easy to transport; when needed, it can be unfolded into cardboard boxes, and its volume is significantly smaller than that of hardwood boxes or plywood boxes of the same volume.

3. Remarkable Buffering Performance

Folding cartons have excellent buffering performance, which is one of their many benefits. Because of its unique structure, which leaves 60–70% of the cardboard’s volume empty, it is able to absorb shock, shield its contents from damage, keep its contents from spilling out during transport, and seal tightly to ensure its contents make it to their destination unscathed.

This means the contents of the package are protected to the greatest extent possible from any potential collisions or impacts that may occur along the way.

4. Convenient

It works well with assembly line techniques. Corrugated boxes have a considerably higher production efficiency than other packaging containers because a fully automated corrugated box production line has been built to make them in huge quantities.

5. Low-Cost

Corrugated cartons simplify automated packaging, which lessens labor requirements and saves money on shipping supplies.

6. Affordable Prices and an Abundance of Raw Materials

Since corrugated paper can be made from a wide variety of raw materials (including corn cobs, bamboo, scrap paper, wheat straw, reed, etc.), it is much more affordable than hardwood boxes of the same volume.

7. Capable of Carrying Numerous Goods

Corrugated cardboard boxes have a wide variety of uses as packing materials on their own. Still, when paired with other materials, such as covers and moisture-proofing sprays. Their potential decreases substantially.

For example, plastic film bushings are used to make a sealed package in the box to pack liquid, semi-fluid, etc., products. Moisture-proof corrugated boxes are ideal for packing fruits and vegetables.

8. Superior Printing Quality

It’s simple to print advertisements on corrugated cardboard because the material absorbs ink well. There are a variety of designs on corrugated boxes, and whatever kind of design you want can be met. One can easily add different design elements or go through a bleaching process to create eco-friendly packaging with high shelf appeal.

9. Minimal Metal

When compared to the production of wooden boxes, the number of box nails needed for the formation of corrugated boxes is negligible.

10. Recyclable

Since corrugated boxes are made of all-natural, biodegradable materials, they quickly and readily return to the earth after being away. It is illustrative because it is reusable and recyclable, which cuts down on packaging costs and pollution.

Not only corrugated paper but also a lot of packaging materials are recyclable, which are very environmentally friendly materials.

The current global carton recycling rate is over 90%, playing a significant role in efficient resource management. Numerous sectors rely heavily on carton boxes because of the many advantages these folding cartons provide.

FAQs

Q1: What products are best suited for folding cartons?

Folding cartons are ideal for lightweight items like cosmetics, pharmaceuticals, electronics, and gourmet foods.

Q2: What is the difference between folding cartons and corrugated boxes?

Folding cartons are made of paperboard for retail display, while corrugated boxes are thicker and stronger for shipping.

Q3: How thick should folding carton paperboard be?

The right thickness depends on product weight, with typical retail cartons ranging from 0.016″ to 0.024″.

Q4: Do folding cartons protect fragile items well?

Yes, with inserts and structural designs, folding cartons can securely hold and protect delicate products.

Q5: Are folding cartons cost-effective for small businesses?

Yes, they are affordable, scalable, and often more budget-friendly than plastic or rigid packaging.

Conclusion

There is a reason for the prevalence of carton packaging. By choosing a folding carton, you’re not just protecting your product; you’re investing in your brand’s image, efficiency, and environmental values. The right carton design can reduce costs, improve customer satisfaction, and give your product a clear edge on the shelf.

Personalize Your Carton Boxes with Packoi Now!

Packoi has years of experience packaging for both small enterprises and Fortune 500 corporations. No matter if it is folding cartons, paperboard boxes, custom packaging, or rigid boxes, there are different product packaging options. You can choose the packaging material of your own choice, from paperboard sheets and recycled newsprint to kraft paper and SBS paperboard.

Contact us immediately for a free estimate on your packaging project. We’ll put you in touch with a live customer service agent who can answer any queries about your folding carton packaging that you may have.