Last Updated on April 30, 2025 by Packoi Team

What material will you use to create your carton packaging?

If you have no idea what your options are, keep reading this article. You’ll learn about the different materials commonly used to make folding cartons.

You’ll also get sustainable tips plus a crash course on paperboard substrates to help you choose the right material for your packaging requirements.

Common Folding Carton Packaging Materials

One of the defining qualities of carton packaging is that it can be stored and shipped flat. That means it requires assembly before you can use it.

Whether it’s a straight tuck box, reverse tuck box, or an auto-lock bottom box, these can all be shipped flat and assembled when needed.

Because of this, the materials that you’ll use should be sturdy and durable enough to allow assembly and disassembly.

Given these requirements, it’s not surprising that the two popular materials for folding cartons are paperboard and corrugated cardboard.

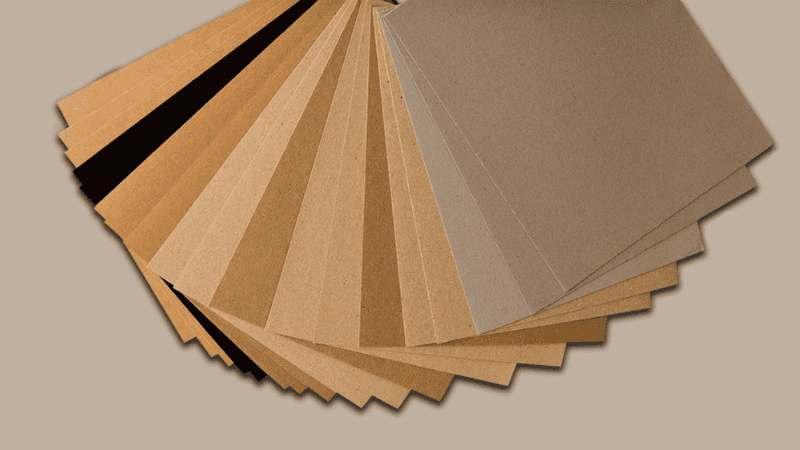

Paperboard

This is a fiberboard that’s made of cellulose material. New paperboard comes from virgin stock from trees. If you’re going to use this, make sure the paperboard comes from responsibly managed forests.

This is thicker than paper, around 10-point or 12-point in caliper. This translates to 10 thousandths or 12 thousandths of an inch.

This is a common material used to create folding cartons because it’s manufactured to minimize cracking even if it’s bent or folded. It’s also made with a special coating to keep it smooth and printable.

Later on, you’ll learn about the different substrates that define the various paperboards that you can use for your folding carton.

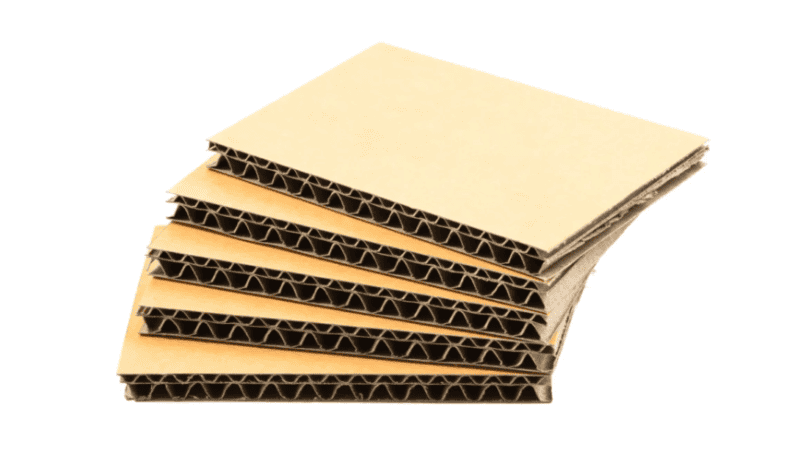

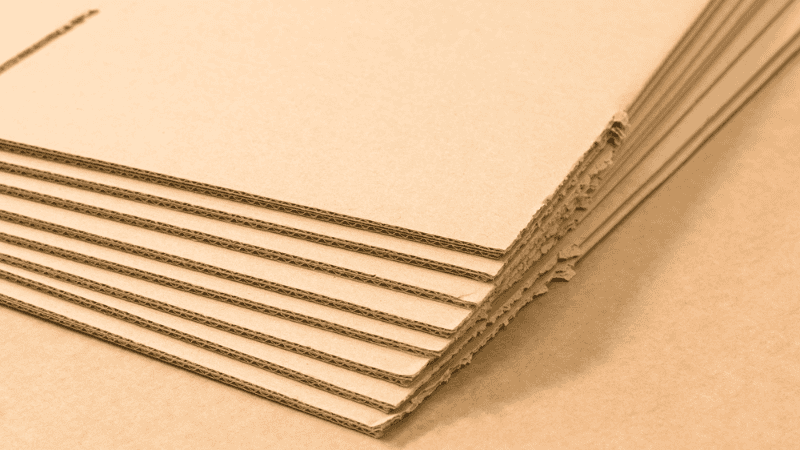

Corrugated Cardboard

Although paperboard is thicker than paper, it’s just one layer of fiberboard. Corrugated cardboard is composed of 3 layers of paperboard. There are 2 flat liner boards and 1 medium board that’s fluted to look ruffled.

Because of this composition, corrugated cardboard is thicker and deemed to be more durable than paperboard. Despite having three layers, it’s still quite lightweight.

This is ideal for folding cartons that are intended for heavier or more fragile products. The corrugated containers provide more protection compared to a single layer of paperboard.

Since paperboard and corrugated cardboard come from trees, they are considered to be sustainable and eco-friendly packaging materials. But being sustainable doesn’t limit your options between these two alone.

3 Sustainable Materials for Folding Cartons

Over the years, the call for more sustainable packaging became greater. The problem with packaging waste was too great, so relying solely on paperboard and corrugated cardboard wasn’t enough.

This is why you’ll start to see folding cartons made of new ,environmentally-friendly materials.

Here are some of the options that you can consider.

Hemp-Based Board

Hemp is a plant with more cellulose and less lignin, making it a more suitable raw material for paper compared to wood. The first paper produced was partly hemp-based.

This is why it’s not surprising that hemp can be used to create folding cartons. What’s even better is that hemp grows a lot faster than trees, even without proper irrigation. You also don’t need to bleach hemp pulp, making it even more eco-friendly than wood pulp.

While some hemp-based boards require a bit of paper stock, it’s still a great alternative.

A downside to this is that hemp leaves a rough surface on the folding carton. This might become a problem if you want a smooth print effect.

Sugarcane Board

This folding carton material comes from a sugarcane plant. When the juice is extracted from a sugar cane, it leaves a dry pulp called bagasse. This is the main material used to create packaging.

Because of the natural components of this board, it’s a popular option for food packaging. It’s not just lightweight, it’s also resistant to grease.

Sugarcane board is also durable enough to be used to create folding cartons. It can also be recycled, making it a very sustainable material to use for packaging.

100% Recycled Paperboard

Recycled paperboard is created from waste paper materials. It’s collected from recycling facilities and repurposed into new folding cartons.

When paperboard waste is sent to the recycling facility, it goes through a process that breaks down and turns the post-consumer waste into recycled fibers. This is then used to create new recycled paperboard.

There are specific substrates that indicate if a paperboard is recycled. Later on in this article, that will be discussed.

This is why, apart from choosing the style, you have to understand the substrate of the paperboard that you’re using. For instance, you can use straight-tuck boxes using URB or Uncoated Recycled Paperboard.

Other options will be discussed in the next section of this article.

7 Substrates for Folding Cartons

Now that you have an idea of what materials you can use, don’t go looking for folding carton styles just yet.

It’s time to talk about paperboard substrates before you choose between auto-lock bottom boxes or reverse tuck boxes.

In the world of folding cartons, it’s important to scrutinize the raw materials and processes used to create the box. Sometimes, the label would say that it’s bleached and coated with specific materials.

However, in truth, substitutions are made that leave the box unsuitable for your packaging requirements.

By scrutinizing the substrates of your paperboard, you can be certain that it suits your print, protection, design, and sustainability requirements.

1. SBS

This is short for Solid Bleached Sulfate. This is the most popular packaging material used in North America, even if it’s one of the higher-priced options.

The composition of this paperboard is pulp fibers from hardwood that are bleached and refined into one-ply paperboards. The fibers are bleached, coated, and polished so they turn white on both sides.

This gives folding cartons a smooth surface that makes them very accommodating to ink. It leads to high-quality print designs by offsetting, among others. You can even use hot foil stamping and embossing on Solid Bleached Sulfate paperboard.

In terms of strength, SBS boards aren’t tear-proof, but they’re very stiff and have good compression strength. It’s great for flavor-sensitive products because the finished paperboard is tasteless and odorless.

2. SUS, CNK, or CUK

This is short for Solid Unbleached Sulfate, Clay Natural Kraft, and Coated Unbleached Kraft, respectively. This has two to three layers that are mostly from long, softwood fibers.

It also has a thin layer of hardwood fibers on the top layer to enhance the smoothness of the surface.

As the name suggests, Solid Unbleached Sulfate is a paperboard that uses unbleached virgin wood pulp – at least 80% of its composition is.

The color of this folding carton is white on top, especially if the Solid Unbleached Sulfate uses a coating that’s titanium-based and opaque. This helps improve the quality of print that it can accommodate.

This is naturally resistant to moisture, so it’s a great option for folding cartons meant for frozen products or those that require refrigeration.

3. FBB or TMP

This is short for Folding Box Board and Thermal Mechanical Pulp, respectively. A folding carton classified under this substrate is composed of a chemical pulp in the outer layers and a mechanical pulp sandwiched in the middle.

The topmost layer of the chemical pulp is usually bleached and then coated with pigment. The layer at the back looks cream. This is the color of the mechanical pulp in the middle, which can be seen through the translucent chemical pulp layer.

Because of the different layers, this creates a folding carton that’s strong and stiff. The coating also allows vivid prints to maximize the design’s visual appeal.

4. CRB, CCNB, or CCWB

This is short for Coated Recycled Board, Clay-Coated News Back, and Clay-Coated White Back, respectively. With the call for more sustainable folding cartons, businesses have started to prefer this paperboard substrate.

It’s made of different post-consumer waste like old corrugated packaging, newsprint, and other secondary paper materials. It’s usually 100% recycled, and 35% of that is post-consumer.

A Coated Recycled Board is made of 8 layers – sometimes even more. The topmost layer is either bleached or semi-bleached. It’s more absorbent, so it requires stronger ink to achieve the desired print quality.

This is the preferred substrate for cost-efficient and sustainable folding cartons. It has adequate tear strength and print quality features, although it’s not the best compared to other substrates.

5. URB

This is short for Uncoated Recycled Board. Like the previous substrate, this one uses 100% recycled fibers. Another term for this material is Chipboard. It’s characterized by the uncoated surface on both sides that’s smooth to the touch.

Folding cartons that use this substrate vary in color. It all depends on the specific recycled material used to create it. So, make sure you get the details from your packaging supplier.

6. CKB

This is short for Coated Kraft Back. It’s a type of paper substrate that’s gaining popularity in North America. It allows businesses to reduce the cost of packaging, specifically folding cartons.

Despite the structure having a 15% to 20% lower weight, it’s still high-quality with enough stiffness to be an effective packaging material.

This paperboard has five layers, and the stiffness comes from the middle layers. The top layer has a double-blade coating to ensure high-quality print designs.

Since this board is kept pure both chemically and microbiologically, it’s a great option for food packaging.

7. UNK or UKB

This is short for Uncoated Natural Kraft and Uncoated Kraft Boxboard, respectively. It’s a paperboard with 2 layers. The top layer is mostly hardwood fiber that gives the folding cartons a smooth touch.

The material and the lack of coating and bleach give this a strong and clean packaging performance, even if it has fewer fibers.

Since it’s uncoated, it doesn’t match the printing quality provided by the coated alternatives. But if you incorporate the natural color of the kraft, you can still have beautifully designed packaging.

Conclusion

Now that you have a better idea of the available materials for your folding cartons, it’s time to choose the best one according to the needs of your product.

The most important job of a folding carton is still to protect your product. You want to ensure that it won’t be compromised in any way.

Other considerations include the folding carton styles. Think about the best material that’ll help the box function effectively.

Understand the strengths of auto-lock bottom boxes or straight tuck boxes compared to reverse tuck boxes. See how the board materials can enhance them, or compensate for any of their weaknesses.

Of course, your brand image should also be considered. If you’re building a reputation for being sustainable, choose eco-friendly materials.

Find the Right Folding Carton Material With Packoi Now!

The technicalities of creating the perfect folding carton for your business may seem confusing, especially if this is your first time encountering the terms. But don’t worry, with the right guidance, you can find the right material that suits your packaging requirements.

If you need assistance, Packoi Printing is here to help. We have extensive knowledge of folding cartons, and we can show you the possibilities that you can use to create your own.

Contact us today, and we can talk about your ideas. We’ll make sure to get back to you with a fair quotation immediately.