Last Updated on September 12, 2025 by Packoi Team

Spot UV printing is a versatile technique that adds a touch of elegance and sophistication to printed materials by creating a glossy and raised effect. This method enhances the visual and tactile appeal of business cards, brochures, luxury packaging, and more. However, it is not an easy technique to master.

In this complete guide, we’ll explore the basics of the Spot UV printing process, its benefits, applications, and tips for effective implementation.

What is Spot UV Printing?

Spot UV printing is the process of screen printing a glossy coating over select parts of an existing design and curing it using ultraviolet (UV) light. The glossy coating is a polymer resin in liquid form that solidifies when exposed to natural (sunlight) or artificial (UV) light.

Like any other finishing technique, UV coating is the final part of the printing process. Once your design is finalized, color-printed onto a surface, and allowed to dry, you can move on to the spot UV coating process.

Spot UV technique precisely covers the selected areas with the UV varnish, creating a distinct visual boundary between the coated and uncoated areas. This unique process creates a contrast between the matte areas and the glossy areas, allowing businesses to highlight important details and branding.

UV coating can also make the colors pop a bit more, giving the final printed product a brighter and higher-saturation appearance.

Standard UV Printing vs Spot UV Printing Press

Standard UV covers the entire printed sheet with the resin coating. This process often suppresses fine details in the print. If your entire surface is glossy and reflects light, it could make text a little harder to read.

For example, if you use standard UV coating on a business card, the resin will coat the entire card surface, giving it a glossy finish.

In stark contrast, Spot UV coating only covers select areas of the print surface. It is a great way to add glossy design elements to your prints without compromising readability.

For example, if you use spot UV printing on a business card, you can choose to cover only the logo area with resin, leaving the rest of the card intact. This will result in a shiny, reflective logo that makes your card stand out from the competition.

What is Blind Spot UV Coating?

Blind Spot UV printing is a special application of UV coating. In this technique, the spot UV layer is printed on a blank surface. The texture and reflection of the resin provide the definition.

This method of UV coating gives your prints an invisible ink look. The design elements stay hidden until they are exposed to a light source. It is a minimalist technique that gives the appearance of luxury and exclusivity.

While the blind spot UV technique has merits, it’s not suited for all applications. Businesses with distinct, colorful branding will not be able to fully utilize their benefits.

How Does Spot UV Printing Work?

As mentioned above, the spot UV process is a finishing technique that adds a high-gloss shine to your print surface or substrate. The UV coating process uses the same design files, with certain areas blacked out.

We can break this complicated process into four phases.

Phase 1 – Design Preparation

- Step 1 – The first step in spot UV printing is to map out design elements that require coating. You can use your existing vector files to create a separate design layer for the UV elements.

- Step 2 – Print a black-and-white copy of the UV map. The black elements represent all the areas where you will apply the spot UV varnish.

Phase 2 – Prepare UV Silk Screen

- Step 3 – Next, we must prepare our UV coating station. First, paint the silk screen (a mesh surface) with a UV-reactive paint layer. Be sure to perform this step in a dark room so you don’t accidentally cure the paint.

- Step 4 – Now, place your black-and-white UV map on the mesh layer. It’s recommended that the UV map and the mesh screen be the same size to ensure proper alignment.

- Step 5 – Expose your mesh layer to a UV light source. The light will cure all parts of the mesh screen except the areas covered by the UV map.

- Step 6 – Wash your mesh layer to remove the uncured paint. You now have a silkscreen blank.

Phase 3 – Base Printing

- Step 7 – Print your designs on the base layer using traditional methods (e.g., offset, digital printing, silk screening). Ensure your printed piece has the same dimensions as your silk screen and UV map.

- Step 7.5 (Optional) – Place your base print under the silkscreen to check the alignment. Readjust and reprint if necessary.

Phase 4 – UV Coating Application

- Step 8—Install your mesh screen on your spot UV coating machine and place your base print under the mesh (silk) screen.

- Step 9 – Now mix your UV resin coating in a clean container and pour a small amount on top of the silk screen. Use a squeegee to push the resin through the mesh screen onto the printed piece. This step will deposit a thin resin layer onto select areas of your design.

Phase 5 – UV Light Curing:

- Step 10 – Lift the mesh screen and gently remove the printed piece. The resin is still wet, so don’t touch the spot UV layer.

- Step 11 – Place your base print with the spot UV layer under ultraviolet light and wait until it hardens. You may also place the print under sunlight to achieve a similar result.

Benefits of Spot UV Printing

High gloss spot UV coating is one of the easiest ways to make your designs stand out. UV printing offers numerous advantages, making it a popular choice for enhancing printed materials.

Here are some of the benefits of using spot UV coating.

1. Visual Appeal

The high-gloss UV coating adds depth to your designs. Light reflections off the printed materials are an excellent eye-catching element to any design. The UV coating makes colors appear more saturated and shiny, something that traditional digital printing cannot accomplish.

2. Tactile Feel

The additional resin layer sits higher than the flat design, giving the final prints a unique tactile feel. As you move your fingers across the printed surface, you can feel a noticeable change in texture as you come across the thin film of resin.

Spot UV printing provides visual and tactile enhancements that set your designs apart.

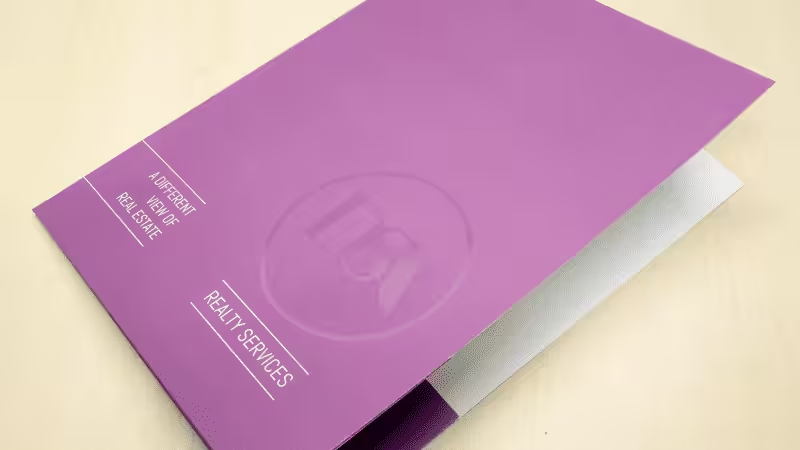

3. Professional Look

While the definition of professional varies from industry to industry, one thing is clear: professional means something that conveys attention to detail and enhances brand credibility.

UV coating adds texture and visual appeal to your designs. It’s a creative way to show that your business puts in the extra effort and instantly elevates the perceived quality of printed materials.

4. Durability

At its core, the UV coating is a layer of hard resin. Resign is more durable than paper and resists scratches, fingerprints, and general wear and tear. It’s a great way to protect your prints and increase their longevity.

Durability is particularly important for bulk-order packaging materials such as paper bags. Various parties will handle such items during packaging, shipping, and last-mile delivery, where scratches and minor damage are expected.

5. Customizability

Of course, we have to highlight the ability to customize design elements like logos, text, and images. UV printing presses can accommodate different material types and thicknesses.

Spot UV coating is suitable for every type of printed item, from business cards to shopping bags to packaging materials.

6. Cost-Effective Luxury

Luxury is defined as a feeling of comfort or elegance, something that isn’t readily available to everyone. In that regard, luxury is exclusivity and rarity.

Brands that don’t opt for additional finishing options, like engraving, embossing, or spot UV coating, are perceived as low-quality. UV coating provides a premium aesthetic to your prints without a considerable increase in cost.

Common Applications of Spot UV Printing

Spot UV printing can enhance any flat-printed design. Here are our top use cases for this unique finishing technique.

1. Business Cards

The spot UV technique is ideal for business cards. It is typically used to add shine and emphasis to logos, names, or other key design elements. Embossed spot UV coatings are particularly popular for business cards; they combine the excellent tactile feel of embossing with the glossy finish of UV.

2. Brochures

Printed marketing materials are particularly well-suited for spot UV coating. Brochures and pamphlets contain lots of text and images that can overwhelm the reader. Use spot UV to highlight key visuals or headlines and draw attention to specific elements such as pricing and dates.

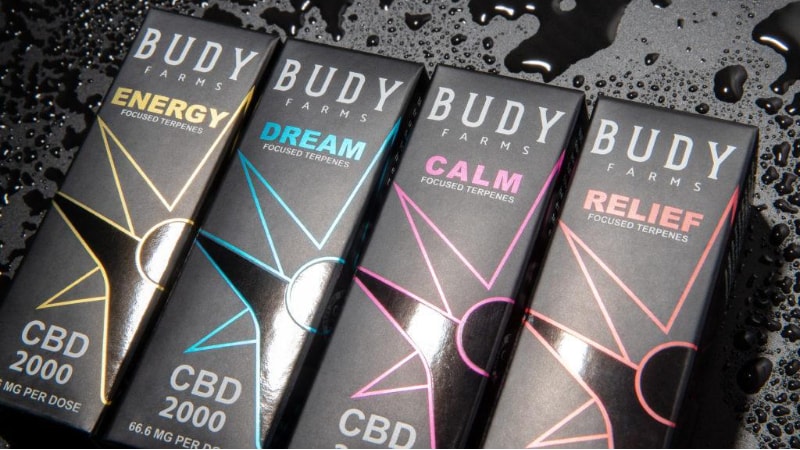

3. Packaging

The packaging industry has grown significantly in the last few years and is expected to reach a trillion dollars by 2027. In this competitive industry, unique and innovative designs have become a necessity.

Generic packaging is no longer attracting customers, which means new businesses are investing in custom packaging materials to stand out in the market.

A spot UV layer on your packaging material will elevate its design, giving it a premium appearance. The spot gloss design is also eye-catching, helping products stand out on grocery shelves.

4. Book Covers

Despite the popular idiom, people do, in fact, judge a book by its cover. A higher-quality cover represents the written materials. Spot UV is commonly used to accentuate titles and author names.

This practice helps fans quickly identify the author’s similar work. Additionally, the protective layer formed by UV book printing helps maintain the beautiful artwork on book covers.

5. Invitations

Wedding invites are personal and represent the excitement of a lifelong union. More and more couples are looking for unique ideas to set their weddings apart from others.

Spot gloss UV wedding invites are gaining popularity among soon-to-be newlyweds. They add a unique texture to the cards and are great for highlighting the names of the bride and groom.

Limitations of Spot UV Printing

Like any other printing technology, spot UV printing has its fair share of drawbacks. Here are three factors you need to consider before making a decision.

- Cost: The overall cost of spot UV printing sits between the incredibly low cost of digital printing and the high costs of embossing and engraving.

- Suitability: UV printing of any type is best suited to flat surfaces with a matte finish.

- Time: The finishing process adds additional production steps, which can result in a longer turnaround period.

5 Tips to Help You Design for Spot UV Printing

Spot UV printing is a complex process with several steps. To achieve the best results, it’s important to carefully plan your design.

Here are some helpful tips to guide your design process.

Tip # 1 – Always Keep Your Designs Clean and Simple

Simplicity is the key to an effective spot UV coating. Excessive use of glossy elements can dilute the overall impact of the design, leading to a cheap-looking feel.

The spot UV layer should stand out against the matte finish of the base material. Limit the use of spot UV to logos, titles, and other important information.

Tip# 2 – Focus on High-Impact Areas

Spot UV will yield the best results when applied strategically. The high-impact areas of any design will be the logos, titles, promotional messages, limited-time offers, discounts, and pricing. This will draw attention to the most important parts of your design and enhance their visibility.

Tip # 3 – Ensure Precise Alignment

Misalignment between the digital print and the UV layer can ruin a design. To ensure the precise application of the UV layer, add alignment markers to the corners of your design.

High-quality printing equipment helps reduce alignment errors.

Tip # 4 – Consider the Surface of the Substrate

The spot UV process enhances everything on the printed surface. Ideally, it should only highlight the design and colors. However, it can also bring surface imperfections to the forefront. Any minor dents and defects will become even more apparent after UV printing.

This process is best suited to smooth surfaces such as coated/laminated paper, plastic sheets, or cardboard. While spot UV can be used on cloth, foams, wood, metals, and other materials, the finished results will vary drastically.

By following these simple tips, you can elevate your designs and maximize their impact.

FAQs

Q1: What is the Difference Between Spot UV and Full UV Coating?

Full UV coating covers the entire printed surface, giving it a glossy finish. Meanwhile, the spot UV technique only covers select parts of the printed surface, such as logos or titles, helping those design elements stand out.

Q2: Is Spot UV Printing Eco-Friendly?

Spot UV printing is more eco-friendly than full UV coating. Full UV-coated materials are more difficult to recycle. However, simple digital printing is the most eco-friendly option.

Q3: Can Spot UV be Applied to Any Material?

Yes. Spot UV can be used on paper, foam, cardboard, plastic, cloth, and metal surfaces. However, the final results will vary based on the smoothness of the material surface.

Q4: How Much Does Spot UV Printing Cost on Average?

The actual cost of printing is determined by the volume of the prints, the quality of the printer, and the design complexity. On average, spot UV printing costs 2-4 times more than standard digital printing.

Q5: What types of products benefit most from Spot UV printing?

Business cards, brochures, packaging, book covers, and invitations gain the most value from Spot UV.

Conclusion

Spot UV printing is an incredibly effective technique that enhances the quality of your printed items. The best part is that it is an optional process that doesn’t affect your existing workflow. In the case of blind spot UV coating, it yields better results than any traditional printing press. However, like with any other printing process, there is an art to maximizing its impact.

Get Custom-Printed Packaging from Packoi!

Packoi is one of the best packaging and printing companies in the world, specializing in high-quality custom packaging and printing. Contact us now to get a quote for your bulk packaging solutions.