Last Updated on March 11, 2025 by Packoi Team

Have you ever received a damaged package or its contents in disarray? We’ve all been there, and it’s not a fun experience. That’s why, in the world of shipping and logistics, packaging is everything!

But did you know that the secret to ensuring your package arrives intact and your customers are delighted is in the packaging fillers, and good void filler protects fill materials? Yep, you heard that right! These unsung heroes not only protect your products but also contribute to the overall customer experience.

So, whether you’re a business owner or just sending a gift, stick around as we take a deep dive into everything you need to know about packaging fillers and good void fillers and fills.

What Is Packaging Filler?

Packaging filler is also called Voil Fill, shipping padding, and box cushioning. The purpose is all the same: to keep your mailer box safe in the hands of customers.

Packaging filler refers to materials strategically used in empty spaces within the packaging to safeguard and secure products during transit. These materials serve a critical role in minimizing movement, preventing damage, and ensuring that items reach their destination in optimal condition.

The primary purpose of packaging fillers is to fill voids or empty spaces within the packaging stand of a package, providing a protective layer around the contents. Various other types of packaging fillers exist, each offering distinct advantages based on the nature of the products being shipped.

Common examples include bubble wrap, packing peanuts, air pillows, paper fillers, custom box inserts, foam inserts, and corrugated inserts. These materials are chosen based on factors such as fragility, shape, and environmental considerations.

Ready to Get Custom Packaging for Your Business?

start with a low minimum order quantity

Bubble wrap, with its air-filled bubbles, acts as a cushion against shocks, while packing peanuts, made from expanded polystyrene foam, provide lightweight yet effective protection.

Air pillows offer extra space with customizable on-demand inflation, while cardboard and paper fillers present an eco-friendly option. Foam inserts, foam-in-place inserts, and corrugated inserts cater to specific-shaped boxes, offering tailored protection.

What Is the Purpose of Packaging Fillers?

The primary purpose of packaging fillers is to safeguard products during the shipping and transportation process. These materials serve as a protective layer within the packaging, minimizing the risk of damage to the external space inside the packaging or the contents of the external packaging.

The key objectives of packaging fillers include shock absorption, preventing movement, and providing a customized solution for various product types.

During transit, packages may be subjected to various shocks, vibrations, and external pressures. Packaging fillers, such as bubble wrap, packing peanuts, tissue paper, and foam inserts, absorb these shocks as a buffer between the product and potential impacts.

By preventing movement within the package, fillers ensure that items remain securely in place, reducing the likelihood of breakage.

Customization is another crucial aspect of packaging fillers. Different products have varying fragility levels, shapes, and sizes, requiring tailored protection.

Packaging fillers offer the flexibility to customize the packaging and add protection solutions based on the specific needs of each item, contributing to a comprehensive and effective shipping strategy.

Overall, the purpose of packaging fillers is to enhance the safety, security, and integrity of products throughout the logistics chain, ensuring they reach their destination in optimal condition.

Exploring the Diversity: 6 Types of Void-Fill Packaging

When it comes to shipping and packaging, protecting the contents of a package is paramount. Void-fill packaging materials play a crucial role in securing items during transit and preventing damage caused by shocks, bumps, and vibrations.

In this blog, we’ll delve into six different types of void-fill packaging, exploring their characteristics, applications, and benefits.

1. Void Filler Wraps

Void filler wraps are versatile and flexible materials designed to fill empty spaces within a package. These wraps conform to the shape of the product, providing enough space with a snug fit that prevents movement during transportation.

Whether it’s a delicate item or a product with irregular dimensions, void filler wraps offer a tailored solution for added protection.

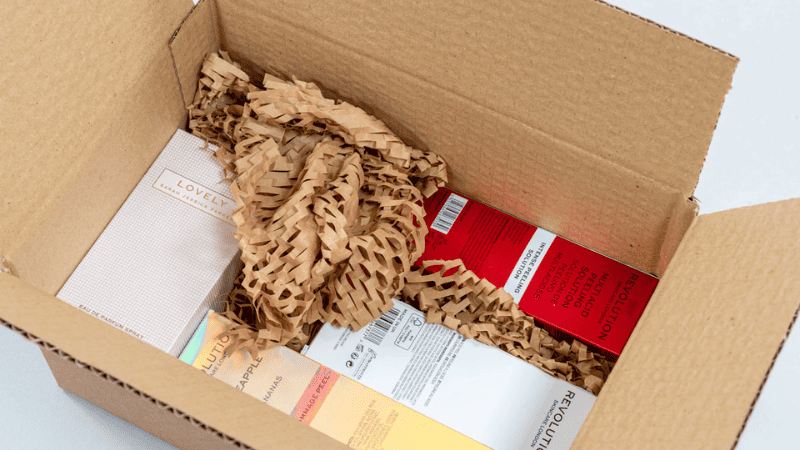

2. Paper Void Fillers

Eco-conscious businesses often turn to paper void fillers as a sustainable alternative. These filters, made from recyclable materials, come in the form of crumpled or shredded newspaper and packing paper only.

They effectively fill voids, offering both cushioning and support for a wide range of products. Paper void fillers are particularly suitable for items with irregular shapes.

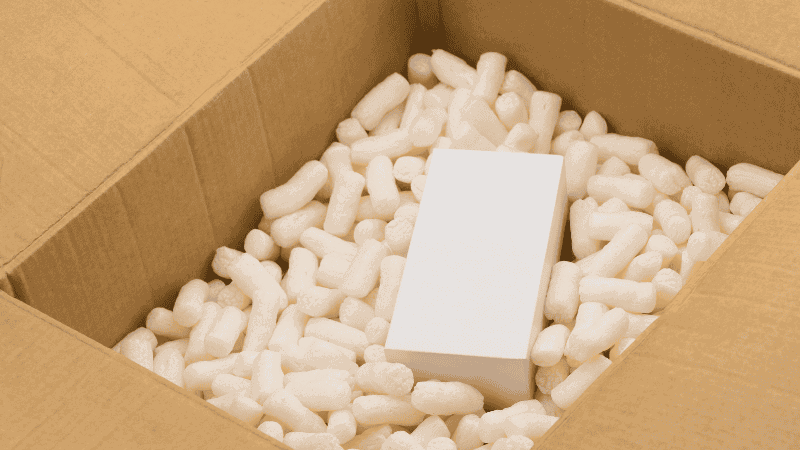

3. Packing Peanuts

Packing peanuts, made from expanded polystyrene foam, are lightweight yet highly effective at providing an extra layer of cushioning. These small, resilient particles fill empty spaces, preventing the contents of the shipping box from shifting.

Packing peanuts are ideal for delicate items and are available in various shapes to accommodate many different types of packaging needs.

4. Foam Sheets

For a more structured approach to the plastic void fill, foam sheets come into play. These plastic sheets provide a protective layer around products, preventing scratches and minimizing the risk of breakage.

Customizable and adaptable, foam sheets are a material often used for items with specific shape requirements.

5. Foam-in-Place

Foam-in-place is a dynamic void-fill solution involving the injection of expanding foam into a bag or box. The foam conforms precisely to the contours of the product, offering a high level of protection. This method is especially useful for securing very fragile objects and high-value items during shipping.

6. Air Pillows

Inflatable and lightweight, air pillows are a popular void-fill choice for larger spaces. These plastic cushions can be inflated on demand, reducing storage space requirements. Air pillows are not only effective at filling voids but also environmentally friendly, often made from recyclable materials.

Choosing the Right Void Fillers: 5 Tips for Your Business

When you’re dealing with e-commerce, transport, and logistics, ensuring that products reach their destination in perfect condition is a top priority. Packing materials, the unsung heroes of packaging, play a vital role in securing and protecting fragile items during transit.

Let’s explore some crucial tips to help your business choose the correct void fillers and enhance the protection of your shipments.

1. Size Matters

Consider the size of your products and their packaging. Void fillers should snugly fill empty spaces without being overly compressive. For smaller items, opt for finer materials like void filler, bubble wrap, or air pillows, while larger items may benefit from more substantial options such as foam sheets or packing peanuts.

2. Shape Matters Too

The shape and form of your products are equally important. Irregularly shaped items and heavy objects may require void fillers with adaptive properties like foam-in-place or custom-cut foam inserts. Ensure that the void fillers can conform to the contours of your products, providing a secure fit that minimizes movement.

3. Assess Fragility

Different products have varying fragility levels. Fragile items demand extra cushioning, making options like bubble wrap, foam sheets, or foam-in-place suitable choices.

For sturdier items packed on paper, eco-friendly solutions like paper void fillers or air pillows might be sufficient, contributing to a more sustainable packaging approach.

4. Consider the Shipping Method

The shipping method plays a crucial role in the selection of void fillers. If your products will endure long-distance ship travel or go through multiple handling points, opt for void fillers with superior shock-absorbing capabilities.

Robust options like foam inserts or air pillows can provide multiple products with that extra layer of protection during extended ship journeys.

5. Quantity in a Box

The number of products packaged in a box influences the choice of void fillers. If you’re packing boxes with multiple items together, consider void fillers that prevent them from colliding during transit.

Packing peanuts or custom-cut foam inserts can effectively keep items in boxes separated and secure during transport, minimizing the risk of damage caused by internal movements.

Unpacking the Green Side: The Carbon Footprint of Various Fillers

Alright, let’s talk about the unsung heroes (or not-so-heroes) of packaging—fillers. You know, those things that keep your favorite mug from having a meltdown on its way to your doorstep. But here’s the twist: They also leave a mark on our carbon footprint dance floor.

Traditional fillers like bubble wrap and packing peanuts? Well, they’ve been known to throw a bit of a carbon party. Made from non-biodegradable plastics, these guys stick around, emitting carbon emissions throughout their lifecycle.

But fear not! There’s a green revolution happening in the world of packaging, with eco-friendly alternatives stepping up to cut some shapes on the dance floor. Recycled paper fillers and biodegradable air pillows are the new cool kids, helping us sway towards a more sustainable beat.

Recycle, Reuse, but Not Always Refuse: Recycling and Disposal Challenges

Now, let’s get real about recycling and disposal. While some fillers, like good old cardboard or tissue paper itself, are MVPs in the recyclability game, others are like tricky puzzle pieces that don’t quite fit.

Take foam inserts or foam-in-place—effective in protection but a bit rebellious when it comes to disposal. Striking a balance between shield-like protection and easy-breezy recyclability is key to winning this eco-war.

Emerging Eco-Warriors: Eco-Friendly Alternatives on the Rise

Drumroll, please! It’s time to meet the new eco-warriors of the packaging world. Mushroom packaging is not just a cool-sounding concept; it’s an actual thing. Using mycelium, this packaging is not only biodegradable but also compostable. Mother Nature would surely give it a high-five!

And that’s not all—the industry is buzzing with plant-based and renewable materials taking center stage. These alternatives promise the same protection without the guilt trip, making them the headliners in the concert of eco-friendly packaging fillers.

Ready to Get Custom Packaging for Your Business?

start with a low minimum order quantity

Conclusion

As we draw to a close, it is evident that the packaging industry is undergoing a shift in its approach to packaging fillers, with a greater emphasis on sustainability and protection.

Conventional materials like heavyweights are being replaced with environmentally friendly options such as recycled paper, biodegradable air pillows, and mushroom packaging.

Get the Right Fillers For Your Packaging With Packoi Today!

Achieving a balance between recyclability and protection is key to improving packaging performance while promoting sustainability. With Packoi working with you on custom design, packaging is not only safe but also environmentally friendly and personalized.

Packoi Printing is here with you to customize the most cost-effective transportation solution to protect your cargo! Contact us to customize your packaging solution!