Last Updated on March 28, 2025 by Packoi Team

For businesses, selecting heavy-duty boxes tailored to product needs can save money and enhance customer satisfaction. A well-fitted box reduces the need for excessive void fill and minimizes movement inside the package.

Whether you’re using standard corrugated boxes or custom shipping boxes, picking the right size helps streamline your packaging process. Our shipping box size guide will help you understand key factors to consider when choosing custom shipping boxes.

Understanding Shipping Box Sizes and Dimensions

Shipping box dimensions are crucial for efficient packaging and cost-effective shipping. Carriers often charge based on dimensional weight. A poorly chosen box size could lead to unnecessary packaging costs.

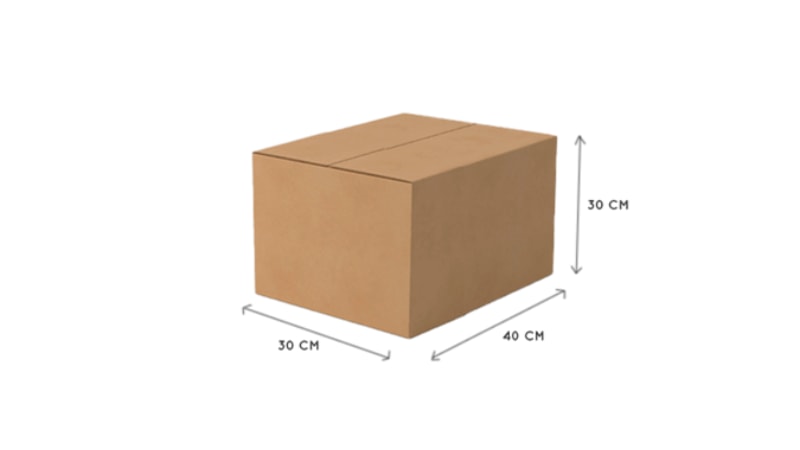

Understanding these dimensions ensures you pick the best RSC boxes for heavy products and other items that need extra care. A shipping box has three main dimensions:

- Length: The longest side of the box

- Width: The shorter side of the box, measured from front to back

- Height (or Depth): The vertical measurement from top to bottom

When selecting heavy-duty boxes, it’s important to measure products correctly and leave enough room for protective packaging materials for shipping. Custom shipping boxes can be designed to fit specific products, reducing wasted space and providing better security for fragile or heavy items.

Shipping carriers have different size and weight guidelines. It’s essential to check their recommendations to avoid unexpected fees.

For example, a heavy-duty shipping box strength guide can help determine how thick a shipping box should be based on the weight of the product inside. If you’re shipping fragile or dense items, choosing the best heavy-duty boxes ensures they arrive intact.

The right packaging strategy not only protects your products but also reinforces your brand’s commitment to quality and efficiency.

Why Shipping Box Size Matters?

Picking the right shipping box size is not just about fitting products inside. It impacts costs, product safety, and brand perception.

Cost Implications

Box size directly affects shipping rates. Carriers use dimensional weight pricing, which means larger boxes cost more, even if they are lightweight.

When you use a box that’s too big for the item, it adds extra weight from unnecessary packaging materials. Choosing the right shipping box size guide can help businesses avoid overspending on shipping.

Product Protection

A properly sized box keeps products from shifting during transit. Too much empty space inside can cause damage, even if protective packaging materials for shipping are used.

On the flip side, if the box is too small, it may not provide enough cushion for delicate items. Selecting heavy-duty boxes designed for product weight and fragility helps prevent breakage and returns.

Branding Benefits

Custom shipping boxes enhance brand perception. Well-sized packaging looks professional and makes a strong first impression. A sleek, well-fitted box shows customers that a business values quality.

Branded, durable packaging for businesses also adds a touch of personalization, making unboxing a better experience for customers.

Step-by-Step Guide to Choosing the Right Shipping Box Size

Selecting the correct shipping box size is crucial to protect products, minimize shipping costs, and enhance customer satisfaction. Follow these steps to determine the best box size for your business needs.

Step 1: Measure Your Product Dimensions

Use a measuring tape to determine the length, width, and height of your product. If shipping multiple items, arrange them in a compact layout to minimize wasted space. This helps in selecting heavy-duty boxes that fit properly without adding unnecessary bulk.

Step 2: Add Extra Space for Cushioning

Leave at least 1–2 inches of space on each side for protective materials like bubble wrap, foam, or crumpled paper. Fragile items may require even more cushioning, while non-breakable goods can fit snugly. Using durable packaging for business reduces the risk of damage and returns.

Step 3: Consider Dimensional Weight Pricing

Popular shipping carriers like UPS, FedEx, and USPS use dimensional weight (DIM) pricing. They calculate shipping costs based on volume rather than the actual weight of a product. The formula for DIM weight is:

DIM Weight = (Length × Width × Height) ÷ Carrier’s DIM Factor

Choosing a box size that optimizes space without increasing costs is essential. A shipping box size guide from your carrier can help you find the best balance between size and shipping fees.

Step 4: Check Weight Capacity & Box Strength

Here’s how weight impacts box selection.

- Lightweight items: Use single-wall corrugated shipping boxes.

- Medium-weight items: Opt for double-wall boxes for added durability.

- Heavy or fragile items: Choose triple-wall or reinforced boxes for maximum protection.

A heavy-duty shipping box strength guide can help you determine how thick a shipping box should be based on your product’s weight.

Step 5: Select the Right Box Style

Different box styles suit different needs:

- Regular Slotted Container (RSC): Standard shipping box with flaps for easy sealing.

- Die-Cut Boxes: Custom-fit designs for snug packaging.

- Telescopic Boxes: Two-piece boxes for added strength and adjustability.

- Mailer Boxes: Ideal for e-commerce packaging with a professional presentation.

Custom shipping boxes help reinforce branding while offering a secure fit for your products. Or, you can opt for the most common box style for your particular product for a snug fit.

Step 6: Optimize for Storage & Stacking

Select mailer boxes that are easy to stack and store. This maximizes warehouse space and keeps inventory organized. Nesting boxes or flat-pack options work well for storage efficiency.

For example, a cube-shaped box is easier to stack than a rectangular one. The size and shape of your shipping boxes should also align with the dimensions of your storage shelves or pallets.

Similarly, consider the weight of your products when selecting box sizes. Heavy items stacked on top of lighter ones can cause damage or crushing during storage.

Step 7: Test Your Box Before Bulk Ordering

Before placing a large order, test a sample box with your product inside. Conduct a drop test or compression test to check if it holds up during transit. This step helps identify whether you need thicker corrugated shipping boxes or additional protective materials.

It’s best to work with a custom product box supplier that offers packaging design and testing services. They can provide recommendations and assist with optimizing your box’s dimensions, material, and features for maximum protection.

Step 8: Order in Bulk for Cost Savings

Buying in bulk from wholesale suppliers lowers per-unit costs. Custom-sized boxes can further optimize protection while minimizing shipping expenses. Investing in the best heavy-duty boxes for shipping saves additional cost in the long run and improves product safety.

Custom Shipping Boxes vs. Standard Boxes – Which Is Better?

When comparing custom shipping boxes and standard boxes, you have to look at two main factors. Let’s review them.

Cost Comparison: Custom vs. Pre-Made Shipping Boxes

Standard boxes cost less upfront. They come in bulk and are ready to use. Custom boxes cost more but reduce wasted space. They lower shipping costs by fitting products better. Standard boxes may require extra padding.

This adds cost and weight. Custom boxes can eliminate unnecessary packaging. They also help prevent damage, reducing returns.

Benefits of Custom Shipping Boxes

Some benefits of custom shipping boxes are as follows:

- Branding: Custom boxes promote your business. They create a memorable unboxing experience. Logos, colors, and designs make your brand stand out. Customers associate quality with branded packaging.

- Protection: Custom boxes fit products perfectly. Less movement means fewer damages. Standard boxes need extra fillers to keep items secure. Custom options reduce the need for excess padding.

- Material Optimization: Custom boxes use the right amount of material. They eliminate waste and lower shipping costs. Standard boxes often require more fillers. This increases both material use and expenses.

- Better Fit: Products fit snugly in custom boxes. Standard boxes may be too big or too small. Ill-fitting boxes lead to product movement and damage. A proper fit means safer transit and happier customers.

Ideally, you should choose standard boxes for general, low-cost shipping. They work for common shapes and sturdy items. Go for custom boxes when product safety matters. They also help with branding and reducing waste.

6 Factors to Consider When Choosing a Custom Shipping Box

Your choice of shipping box affects the cost, protection, branding, and sustainability of packaging. Here are the key factors to consider before making a decision.

Factor 1: Fragility of Items

Delicate items need strong packaging. Glass, ceramics, and electronics require extra protection. Custom boxes can be designed to fit snugly, which prevents movement and reduces damage.

Standard boxes may need extra padding. Bubble wrap, foam, or crumpled paper can help. However, too much filler adds weight and cost. Custom inserts can provide better protection without waste.

Factor 2: Stacking and Storage Requirements

Will the boxes be stacked in a warehouse? If so, strength matters. Weak boxes collapse under heavy loads. Corrugated board boxes with double or triple walls offer better support.

Custom boxes can be reinforced for stacking. Standard boxes may not always be strong enough. Consider the box size as well. Oversized boxes take up storage space. Compact packaging maximizes storage efficiency.

Factor 3: Sustainability Considerations

More businesses are moving toward sustainable packaging. Custom boxes can be made from recycled materials. Some options use biodegradable or compostable materials.

Standard boxes may not always be eco-friendly. Right-sized custom boxes reduce waste. They also lower shipping emissions by reducing package weight. Eco-conscious packaging appeals to modern customers.

Factor 4: Shipping Costs

Carriers charge based on weight and dimensions. Oversized boxes cost more to ship, so using a box that fits the product reduces costs. Standard boxes might be too big, requiring extra padding. Custom boxes eliminate wasted space and lower dimensional weight fees.

Factor 5: Branding and Customer Experience

Another benefit of custom boxes is the ability to add branding elements. You can digitally print logos, taglines, and product images on the box with printing plates to enhance brand recognition and create a memorable unboxing experience for customers.

Custom boxes also allow for more creative packaging designs that can make a product stand out from competitors on the shelf or during shipping.

Factor 6: Weather and Moisture Resistance

Shipping in humid or rainy conditions? In that case, custom boxes can be reinforced with moisture-resistant materials or coatings to protect the product during transit. Standard boxes may not provide enough protection in these conditions, putting the product at risk of damage.

In addition, custom boxes can also be designed with additional weather-resistant features such as secure closures and inner cushioning to prevent water from seeping into the box and damaging the contents.

How to Improve Unboxing Experiences With Custom Shipping Boxes?

Custom packaging enhances product safety and improves the unboxing experience. It also helps businesses stand out. Here are key custom packaging options to consider.

Use Inserts, Dividers, and Extra Cushioning

When you’re shipping delicate or fragile products, it’s important to ensure that they arrive at their destination in one piece. Custom packaging allows you to create inserts, dividers, and extra cushioning to protect your products during transit.

These can be specifically designed for the shape and size of your product, providing a snug fit and preventing any movement or damage. Inserts are particularly useful for electronic devices or other items with multiple components that need to stay organized during shipping.

Dividers can also be used to separate different parts of a product, such as stacked plates or glasses. Extra cushioning, such as bubble wrap, helps protect delicate items.

Choose Eco-Friendly Packaging Solutions

Since customers are becoming increasingly environmentally conscious, it’s important for businesses to consider the environmental impact of their packaging choices. Custom packaging lets you select eco-friendly options such as recycled cardboard.

Kraft paper, compostable mailers, and water-based inks are great options. Eco-friendly choices improve your brand’s reputation and appeal to conscious buyers.

Boost Customer Loyalty with Unique Packaging

Did you know you can use custom packaging to make a lasting impression on your customers? Personalized packaging can create an unforgettable unboxing experience for your customers.

Printed logos, branded tape, and thank-you notes add value. Similarly, high-quality packaging shows professionalism and care. Customers are more likely to reorder from brands with great packaging.

Ways to Reduce Shipping Costs with the Right Box Size

Carriers use dimensional weight (DIM) pricing to charge based on box size, not just weight. Large, lightweight boxes cost more to ship.

If a package takes up too much space, it gets priced at a higher rate. Using oversized boxes with excess filler increases shipping expenses unnecessarily. Let’s look at ways to minimize shipping costs when designing your shipping box for packaging.

Choose the Smallest Box That Fits Your Product

Oversized boxes lead to wasted space and higher costs when used for shipping purposes. A right-sized box reduces the need for extra padding. You can test a few different box sizes to finally find the one that’s optimal for your products.

Use Custom Boxes Instead of Standard Sizes

Custom boxes fit products perfectly, eliminating the need for excess cushioning. This reduces overall weight and shipping fees. Plus, custom boxes can help create a unique brand identity for your company.

Use Inserts and Dividers for Compact Packing

Custom inserts keep multiple items secure while reducing packaging volume. They help maximize space efficiency inside the box. The following table shows the use cases of dividers and inserts.

| Insert/Divider Type | Use Case | Benefits |

|---|---|---|

| Foam Inserts | Fragile items like electronics and glassware | Shock absorption, prevents breakage |

| Corrugated Dividers | Multiple small products in one box | Keeps items separated, prevents shifting |

| Molded Pulp Inserts | Eco-friendly packaging for fragile goods | Biodegradable, offers good cushioning |

| Plastic Inserts | High-value or luxury products | Adds premium feel, protects delicate items |

| Cardboard Partitions | Bottles, jars, or cosmetics | Prevents collision, organizes products |

Optimize Packing Techniques for Efficiency

Arrange products tightly within the box to prevent shifting. Avoid unnecessary layers of wrapping that add bulk. You can also use different packing techniques like nesting, stacking, or rolling to reduce the overall size of your package.

Consider Flat Packaging When Possible

Some products can be shipped flat, reducing dimensions. For example, clothing can be folded neatly and shipped in a flat envelope instead of a bulky box. This way, you reduce your environmental impact by using less material and save shipping costs.

Conclusion

Choosing the right shipping box depends on product fragility, cost, sustainability, and branding. Custom packaging enhances protection and reduces waste. Optimizing box size lowers shipping costs and improves efficiency.

By refining your packaging strategy, you can save money, protect products, and enhance customer satisfaction for long-term business success.

Ask Packoi to Choose Your Best Shipping Box Size Today!

Planning to optimize your shipping strategy with cost-effective and protective box choices? At Packoi, we provide custom boxes in bulk. Reach out to us to get custom-printed shipping boxes.