Last Updated on April 15, 2025 by Packoi Team

Custom packaging costs vary greatly depending on various factors such as materials, sturdiness, order quantity, and customization elements like full-color printing. However, we can give price estimates to help small business owners, e-commerce brands, and even retailers understand the market.

To help, we’ve written this guide detailing the cost breakdown of custom packaging for all kinds of businesses. The guide is based on our industry experience, market research, and the latest trends.

Custom Packaging Costs: Price Estimates You Need to Know

Here are the different tiers of custom packaging prices. For your ease, we’ve listed the technical terms and their meanings at the end of this section. All of these price ranges are for orders of more than 1000 units.

Low-Range Custom Packaging

Small businesses looking for custom packaging boxes to improve their branding and shipping can choose from the options below. These affordable, low-cost options provide basic functionality with minimal customization.

Folding Cartons

Folding cartons are packaging boxes that can carry things like food, cosmetics, or small retail items. Typically, they are made from 18 pt (1 point = 1/1000”) SBS (solid bleached sulfate) paperboard, which is lightweight yet durable. 4-color printing, which offers vibrant designs, can cost between $0.50 and $1.50 per unit.

Flexible Packaging

Flexible packaging refers to pouches or bags that readily change shape when filled or during use. They usually carry snacks, powders, or lightweight goods. It can be waterproof, depending on the quality. The materials used are laminated films made from plastics, aluminum, paper, and kraft paper. With basic custom prints, the price varies between $0.25 and $0.75 per unit.

Medium-Range Custom Packaging

Medium-range custom packaging offers a unique balance between cost and quality. Mid-tier to large-scale businesses adopt this kind of packaging. Due to the higher price, the packaging usually turns out to be more visually appealing.

Corrugated Box

Boxes made from corrugated cardboard are a great fit for e-commerce products, especially fragile or heavy products. A 200# Kraft, a grade of corrugated cardboard known for its high durability, featuring 4-color printing, can cost $2 – $3 per unit.

Plastic Clamshells

Plastic clamshells are best for electronics, hardware, or delicate items. They are made from PET and PVC and feature custom-fit labeled inserts. They can cost between $1.50 and $3.00 per unit.

Rigid Set-Up Boxes

Rigid Set-Up containers are known for their premium feel and are ideal for luxury packaging. The prices typically range from $5 to $10 per unit.

High-Range Custom Packaging

High-end custom packaging speaks for itself, providing a luxury feel, enhanced aesthetics, and durability. It offers efficient marketing and branding opportunities.

Rigid Set-Up Boxes

It is the same as we discussed before in the mid-range section, but better. These Rigid set-up boxes are made from 120 pt (thickness) chipboard with exquisite designs made from 4-color printing.

It may also feature embossing and foil stamping. Best suited for jewelry, electronics, and premium gifts. The custom boxes typically cost around $10 and can increase based on the customization level.

Luxury Packaging Boxes

Handmade boxes, crafted with high-end artisanal skills and premium materials such as silk or laser-cut foam inlays, fall under this category. They’re ideal for luxury items and can be customized to align with a brand’s corporate identity.

Several factors, such as design complexity, material quality, and intricate detailing, drive high-end packaging costs. The prices highly depend on the package’s customization, and it’s difficult to give an estimate. Custom designs typically come at a premium due to the extra effort involved in both design and production.

| Price Range | Type of Packaging | Estimated Cost/Unit | Best For |

|---|---|---|---|

| Low | Folding Cartons, Flexible Packaging | $0.25 – $1.50 | Small products, budget-friendly solutions |

| Medium | Corrugated Boxes, Clamshell | $1.50 – $10.00 | E-commerce, retail, durable products |

| High | Rigid Boxes, Eco-Friendly | Starting from $10 | Luxury or high-end items |

9 Important Factors Affecting Custom Packaging Costs

As we discussed above, the price of custom packaging varies depending on numerous factors. That is why we can only talk about estimates. Here are the factors that affect the custom packaging cost.

1. Type of Material (High Impact)

The material type has the highest impact on the packaging cost. There are premium materials like rigid chipboard, kraft paper, and multi-layer corrugated boards, which are expensive but highly durable. They are good for weather and impact protection. Standard cardboard and paperboard usually cost less.

The first quarter of 2024 saw a significant price hike in Kraft paper and multiple fiber paper globally. These trends of increased prices in North America will likely continue in 2025. Eco-friendly materials with biodegradable and compostable properties typically have higher production costs, which makes them pricier than traditional packaging.

The type of material can indirectly affect the cost. As heavier, more durable material also weighs more, increasing shipping and transportation costs.

2. Quantity and Order Size (High Impact)

Next up is the quantity of product required for the project. Larger orders can significantly reduce the cost per unit, making packaging economical. Each manufacturer has certain criteria for Minimum Order Quantity (MOQs), which significantly affect the overall cost. A company can get discounts if they are willing to maintain a long-term demand for large orders.

Small businesses often struggle to find inexpensive custom packaging because their order quantity is low. Typically, smaller orders of less than 500 units of custom packaging have high per-unit costs because of the setup fee needed for setting up the printing and die-cutting process.

The order quantity can have such a profound effect that a folding carton may cost $1 for less than 500 units, but the same can be purchased for as low as 15 cents.

3. Customization and Design (Medium to High Impact)

Customizing your packaging can increase the cost if the designs are too complicated. The opposite is true as well if you are going the minimalistic route.

Creative designs with vibrant colors increase the price due to additional color printing costs and production time. Similarly, unique shapes, die-cut windows, inserts, or magnetic closures add to the overall cost. The reason behind this price hike is that such designs often require specialized tooling and experienced craftsmanship.

Brands that want a personalized brand identity also hire design services, which can add to the overall cost. Such design services are available by the manufacturer as well as individual designers. The kind of packaging box also plays a role. For example, a rigid box can cost up to 50-100% more than folding cartons.

4. Printing and Finishing Options (Medium Impact)

The printing method is often chosen based on order size to balance cost and quality. For small orders, Digital Printing is preferred. It involves directly transferring designs to the printing material using a color printer.

However, for large orders (more than 500), Offset Printing is a better option. It involves transferring designs from a metal plate to a rubber blanket, which prints images on the packaging material.

Similarly, the color options for printing, like the 4-color or single-color processes, can affect the pricing. There are also numerous finishing options like lamination, embossing, foil stamping, and varnishing that matter. Expect premium finishes to add $1-$2 to the final price of a single usage.

5. Packaging Durability and Strength (Medium Impact)

This is more of a concern for companies that sell delicate products or food items that require protection from the environment. Durability directly influences the material selection, which then changes the cost.

Typically, corrugated boxes are used for fragile stuff, which is costly. Similarly, protective inserts made from foam (or similar material) are necessary for extra protection for high-end products.

Simply switching from a single-wall corrugated box to a double-wall one can increase the overall price up to 4 times. However, you don’t want to compromise the safety of your product, so investing in durable packaging will yield long-term dividends.

6. Lead Times and Production Speed (Low to Medium Impact)

Rush orders for packaging will cost you more because of expedited labor and material sourcing. It’s not that big of a concern, and its impact on overall cost is low. Usually, businesses that require quick turnarounds may face surcharges or limited design options due to time restrictions.

You can expect an increase of 10% to 20% in overall packaging costs for rush orders. Such price increases can easily be avoided with proper time management.

7. Eco-Friendly Packaging Costs (Medium to High Impact)

Eco-friendly materials are generally pricier than traditional ones. However, the prices are becoming reasonable every year thanks to technological advancements. Biodegradable or compostable materials are more expensive than plastic and paperboard.

Sourcing packaging from manufacturers who have FSC (Forest Stewardship Council) or BCorp certifications may add further costs, but it enhances the brand’s eco-friendly credibility. You’ll also be avoiding strict regulations placed in some areas against plastics and toxic materials. Additionally, they cater to environmentally conscious consumers and offer long-term benefits.

8. Shipping and Distribution Costs (High Impact)

Shipping and distribution can become a major factor when purchasing custom packaging. The size, weight, designs, and material can all affect the business’s shipping volume. FedEx and UPS (American couriers) charge based on dimensional weight, meaning bigger and heavier rigid boxes cost more to ship.

Streamlined and flat-fold packaging is lightweight and consumes very little space, making it really cost-effective. Odd-shaped packaging may require customized shipping cartons, which can increase the cost.

9. Packaging Testing and Certifications (Low Impact)

Lastly, testing the packaging for strength, durability, and safety can slightly increase the overall costs. These tests are either done by the manufacturer itself or by a testing laboratory.

Common examples of such tests are the Edge Crush Test (ECT) and the International Safe Transit Association (ISTA). Many other tests and certifications ensure the packaging meets regulatory and product-specific standards. These tests become crucial if you plan to ship fragile or high-value products.

Proven Ways to Reduce Custom Packaging Costs For Maximum Profits

Custom packaging doesn’t have to be a burden on your company’s revenue. Here are a few ways you can reduce the costs and generate massive profits.

1. Optimize Packaging Size and Weight

This is a widely used cost-reduction strategy as smaller and lighter packaging lowers material costs but also significantly reduces shipping fees. Size-efficient packaging designs can exploit the dimensional weight aspect, which can further reduce costs. But this requires input from a skilled designer.

2. Optimize Material Usage

Optimizing material selection can improve your costs. If it meets the minimum safety and durability requirements, you don’t need to opt for expensive material. Additionally, you can customize the box dimensions to fit the product snugly, saving overall space.

3. Order in Bulk

Bulk purchasing is a great way to reduce costs and get discounts. A regular subscription will also help you get good procurement offers. Manufacturers prefer bulk orders because they reduce production setup fees. Also, rush orders should be avoided to avoid expedited production fees.

4. Use Standard Box Sizes

Standard sizes are cheaper as they are quicker to produce. By using commonly used box dimensions, you can almost certainly get exciting discounts.

5. Source Locally

Sourcing from local suppliers can reduce shipping costs and lead time compared to importing packaging material. However, it is a double-edged sword, as sometimes sourcing from manufacturing hubs like China can yield better deals.

6. Negotiate with Suppliers

A lot of people don’t realize this, but effective communication and negotiation with suppliers can lead to discounts and partnerships. Your company can get long-term contracts for better pricing.

7. Use Eco-Friendly and Sustainable Materials

Using eco-friendly materials can reduce the packaging price in the long run. While sustainable materials can improve brand image, lead to long-term profits, and reduce the environmental impact, they may be initially expensive.

Some biodegradable materials are less expensive than others, like substituting kraft paper for more expensive bioplastics. All in all, the use of eco-friendly materials requires careful planning and a delicate balance between total cost vs. perceived brand value.

8. Minimize Design and Printing Costs

Simplifying packaging designs and the use of color can significantly reduce the printing cost, making the custom packaging much more economical. Using 4 color models does make the designs vibrant and aesthetically pleasing, but can also spike the price.

Another way to reduce the packaging cost is by using pre-designed templates or standard designs to save on cost. Hiring an experienced external designer with a strong portfolio can elevate your packaging design, but exploring in-house printing options or negotiating with printing vendors can help achieve stunning results at a more economical cost.

Real-Life Examples

Let’s look at the real-life examples of companies that were able to reduce packaging costs by adopting the methods we’ve mentioned above.

1. Amazon

Amazon Frustration-Free Packaging (FFP) brought up new packaging guidelines for sellers to reduce packaging material and simplify the unboxing experience of customers. By optimizing material, dimensions, and designs, Amazon FFP was able to significantly reduce packaging waste by up to 16%. Additionally, the packaging is 100% recyclable.

2. Puma

Puma, a world leader in highly efficient sportswear, has replaced traditional shoeboxes with recyclable and lightweight bags called “Clever Little Bags.” This ingenious design helped reduce packaging weight by 65% and saved 8,500 tons of paper annually.

3. Lush

Lush Cosmetics has introduced eco-friendly packaging that is made from biodegradable and compostable materials like cardboard and corn-based packing peanuts. It has a great positive impact on the environment and attracts business-conscious customers, leading to increased sales and fostering loyalty.

4. Glossier

Glossier, a beauty brand, came up with a simplistic yet genius packaging design that uses single-color prints on recyclable material like pink bubble wrap pouches and plain cardboard boxes. It’s minimalistic and chic at the same time. Such designs lower packaging and printing costs while maintaining a strong, recognizable brand aesthetic. They have truly mastered the art of minimalistic packaging.

Shipping Costs and Logistics

Getting to know the complexities of shipping costs and logistics will help you set a budget for custom packaging more efficiently.

Factors such as weight, size, and distance have a huge impact on shipping costs. To get the best out of custom packaging, the company must research different methods, such as air or ground shipping. One way companies reduce shipping costs is by optimizing packaging that fits products snugly.

Recently, shipping companies have introduced new policies to grab the business of small companies, which is a breath of fresh air in the increasingly competitive market. FedEx and UPS have significantly reduced their prices for this holiday season.

Shipping depends on numerous factors, and it may sometimes seem counterintuitive. Sourcing products locally in the USA may cost more or take more time than shipping from China. However, companies can utilize such logistics aspects to buy profitable custom packaging.

Custom packing can be designed to optimize the dimensional weight charge. For example, IKEA flat-packs its furniture to reduce packaging volume and lower shipping costs. It also reduces the environmental impact.

Lastly, partnering with a packaging supplier can help optimize shipping costs and logistics. Experienced suppliers often collaborate with logistics providers to select efficient shipping routes and appropriate modes of transportation, reducing both costs and transit times.

Maximizing the Value of Custom Packaging

How can you make the most out of the custom packaging? Here, we share a few tips to help you with it.

Enhance the Customer Experience.

Custom packaging should be customer-centric. The aim is to use this unique opportunity to enhance brand identity, improve customer experience, and increase product protection. It’ll improve brand loyalty and supplement your marketing efforts.

Prioritize functional design that aligns with your brand voice. For example, vibrant and chic designs attract a younger audience. It’ll also improve customer loyalty and social media shares.

Highlight Product Features and Benefits

Use customized packaging to highlight key features and benefits of your product. Showcase details like ingredients, functionality, or eco-friendliness, which makes packaging more appealing. Boost sales by clearly communicating product value and aligning with customer priorities.

Brand Identity

Reinforce brand values by using creative messaging and slogans on packages. Ensure consistency across marketing channels. Use custom packaging to evoke emotional connections with customers, fostering trust. Make it more memorable, engaging, and relatable by using traditional themes. Such an initiative will help your business stand out in the competitive market.

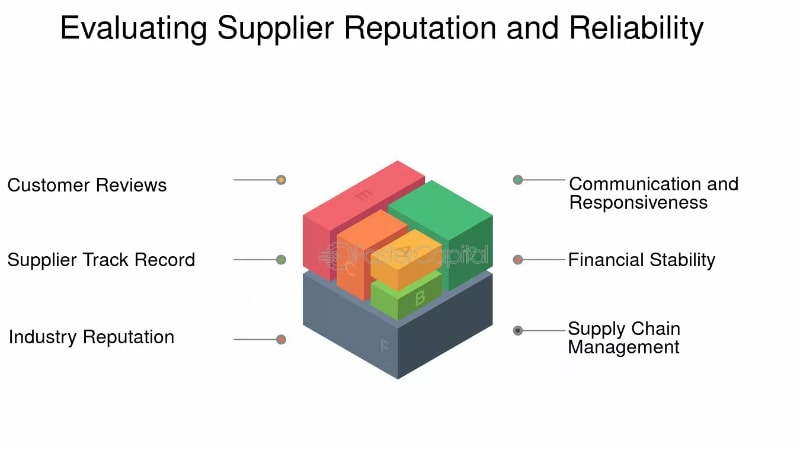

Working with Custom Packaging Suppliers — Tips for Better Business

Collaborating with a custom packaging supplier can streamline your packaging needs and optimize costs.

1. Request Quotes and Compare Prices

Start by requesting quotes from different suppliers and comparing the prices. Also, ask about the additional or hidden costs, like shipping or setup fees, to ensure full transparency. Discuss customization options to check if it’s within their capabilities to produce your desired packaging.

Most manufacturers are open to providing free quotes. Ensure clear communication and present all of your expected deliverables upfront. Be careful about comparing suppliers. Don’t just focus on factors such as cost, as a supplier can be cheaper but may have a poor delivery process, or the management may not be cooperative. A smart way is to judge the manufacturer’s capability on multiple fronts.

2. Pricing Structure

Understand the supplier’s pricing structure and request bulk discounts or flexible payment terms. Usually, suppliers are more willing to cooperate on long-term projects. A transparent pricing model helps negotiate better rates and avoid any hidden charges.

3. Lead Times and Delivery

Companies have different lead times and delivery systems. Ensure timely productions and lead times that suit your company’s shipping needs.

4. Communication Channel

Choose a supplier with clear and open communication. Having such channels will ensure suppliers adapt quickly to changing demands and unforeseen challenges.

Another aspect of smooth communication channels is a strong customer support service that can help resolve issues quickly. The supplier doesn’t need to be the cheapest option, but offering a dedicated account manager for seamless communication is highly recommended.

5. Request Packaging Samples

Ask suppliers to send you packaging samples to help you evaluate quality. In the case of custom packaging, this becomes more relevant as you can get an idea of how the end product will turn out. Ordering a prototype before a bulk order will help ensure the design fit and durability meet expectations.

6. Eco-friendly Options

Look for eco-friendly packaging options that align with your packaging needs. Also, ensure the manufacturer complies with all the sustainable practices. You can do that by requesting their certifications.

7. Long-Term Relationship

Build long-term relationships with reliable suppliers to ensure consistent cost-efficiency. However, if a supplier consistently fails to meet your demands, don’t hesitate to end the partnership—continuing with an underperforming supplier can negatively impact your customers and business reputation.

8. Hire Specialized Suppliers

Hiring manufacturers who specialize in certain fields can help you order high-quality custom packaging. They can offer innovative packaging solutions tailored to your products that general suppliers might not be able to. Go for specialized suppliers who have certifications like FSC, ISO, or others to back up their claims.

9. Supplier Reputation and Future Growth

Research reviews and testimonials to assess the supplier’s credibility. A supplier with a strong reputation in the market can lead to sustainable collaboration. A long-term collaboration with the supplier will increase order volumes, which will help you scale your business seamlessly. It will ensure consistent packaging quality during high-demand periods.

Conclusion

We’ve covered many different aspects of custom packaging, like printing, material, types, and shipping. Next, we discussed how you can reduce the packaging cost, how to deal with the suppliers in the packaging industry, and how to maximize your packaging order. It’s hard to give the exact cost of custom packaging, but our estimates will surely help you in the right direction.

Get Premium, Sustainable Custom Packaging at the Best Price

Packoi is a world-leading provider of custom packaging and printing, with over two decades of experience catering to e-commerce and retail businesses worldwide. Contact us today for a quote.