Last Updated on August 18, 2025 by Packoi Team

Pharmaceutical packaging is the protective shield that ensures lifesaving drugs reach patients safely. Without it, medications would be vulnerable to contamination, degradation, and tampering. Can you afford the risk of compromised products reaching consumers?

Certainly not.

It is for this exact reason that you should know the ins and outs of pharmaceutical packaging. This information will ensure you make informed decisions that meet pharmaceutical regulatory requirements and also align with your business’s sustainability goals.

Today, about 71% of people buy products simply because of their environmentally-conscious packaging.

Eco-friendly medicine packaging gives you an edge, especially when it comes to attracting the growing number of consumers who appreciate the commitment to environmental sustainability.

The Importance of Packaging in the Pharmaceutical Industry

Packaging ensures the safety and efficacy of the pharmaceutical products. To this point, you know that pharma packaging is more about protecting what’s inside than aesthetics.

It basically shields medicines from external factors. We are talking about moisture, light, and air. These can degrade the potency of your drugs.

You need proper packaging to ensure your products reach patients in perfect condition to deliver the intended therapeutic effects.

Other than protection, packaging also serves as a means of tamper evidence to assure consumers that the products they are about to use haven’t been altered. This sense of security fosters trust between your business and customers.

Don’t forget that packaging also facilitates dosing and administration. You see, the right packaging ensures that patients receive the correct dosage of medication (whether it’s through blister packs, vials, or syringes). You can add dosage instructions, expiration dates, and other essential information on the packaging.

So, packaging is one of the best ways to minimize dosing errors. It also ensures your business meets regulatory requirements.

6 Common Types of Primary Pharmaceutical Packaging Materials

Primary pharmaceutical packaging is the material that directly contains medications. This is specially designed to keep medicine effective until your patients use it.

To put it simply, whenever you pick up a pill bottle, what you are holding is the primary pharmaceutical packaging. And here are the types most pharma companies use:

1. Vials

These are small containers, mostly used to store liquid medications. They’re made of glass or plastic to offer durability and protection for your pharmaceutical products.

Plastic vials, although not as eco-friendly as glass ones, are lightweight and shatter-resistant. This ensures you transport your medicines safely to your patients.

While the two may be different, they both offer prevention against contamination. Their compact size also makes them convenient for storing and transporting medications.

2. Bottles

Most products are packaged in bottles for a reason. They’re versatile and sturdy, and some types are eco-friendly.

Bottles commonly used in pharmaceutical packaging are usually made from high-quality plastics like PET (Polyethylene Terephthalate), HDPE (high-density polyethylene), or sometimes glass.

These materials keep your products safe from moisture, light, and contamination. Bottles are generally easy to transport and also perfect, especially if you want to store liquids, tablets, or capsules. This makes them a smart option for packaging pharmaceutical products.

3. Blister Packs

Blister packs also offer safe and efficient pharmaceutical packaging. These packs are made of plastic, aluminum, or a combination of both. Unlike the other types, blister packaging is made of a plastic mold (blister) and a backing material sealed together.

It holds each medicine neatly in its compartment. This makes it simple for patients to keep track of their medication regimen.

Versatility is another area where this type of packaging shines. You can customize them to fit different pill sizes and shapes to make them a perfect fit for your specific medication needs.

4. Sachets

These are the small packets most pharmaceutical companies use to hold individual doses of drugs, just like blister packs. Because they are made from paper, aluminum, or plastic, they are ideal as a convenient and eco-friendly way to package medications.

Their compact size reduces material usage and transportation costs, making them an efficient choice for both you and the environment.

Sachets’ single-dose format promotes medication adherence. That is, they ensure patients get the right amount of drugs every time. So, while these little packets may seem small, their impact on your business and the planet is huge.

5. Syringes

Syringes are small cylindrical tubes with plungers commonly used to inject or withdraw fluids. While they are common for drug administration, prefilled syringes are becoming increasingly popular for their convenience and safety.

These are syringes that come preloaded with a precise dose of medication, sealed, and ready for immediate use.

This type of syringe reduces the risk of dosing errors since the medication is prepared under controlled conditions.

Prefilled syringes are a convenient, safe, and reliable option for pharmaceutical packaging.

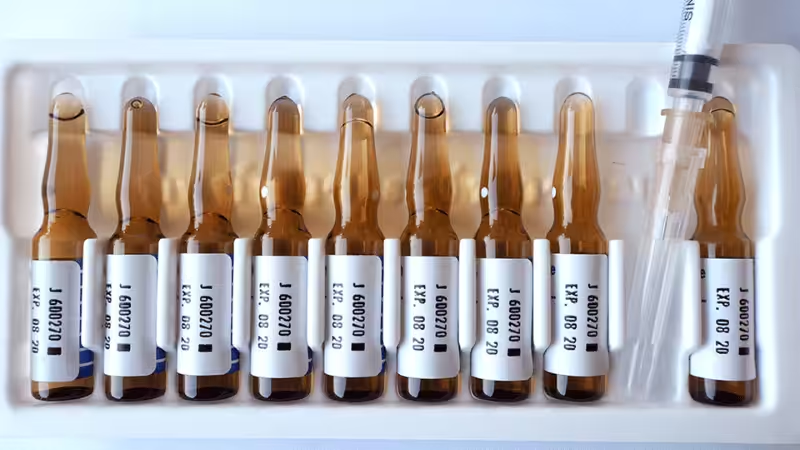

6. Ampoules

Have you seen the small, sealed containers often used to store pharmaceutical liquids, such as vaccines? These may be ampoules.

Ampoules are mostly made of glass, although plastic versions exist, too. This packaging is popular because of its ability to keep contents sterile.

Other than efficacy and safety, ampoules are sealed. This means no air or moisture can get in. This prolongs the shelf life of the product.

Also, glass ampoules are recyclable and, most importantly, don’t leach harmful chemicals into medication. This is one of the reasons they are an eco-friendly choice. Therefore, if you choose to go with this option, you are prioritizing both efficacy and environmental responsibility. This is ideal for your business, right?

4 Secondary Packaging Materials for Pharmaceuticals

This is the second layer of protection for medicines. When you buy a pack of pills, they often come in a box. That box is the secondary packaging. Its purpose is to keep the medicine safe from things like light, moisture, and damage while it’s being stored or transported.

While the primary packaging (like blister packs or vials) keeps the medicine itself safe, the secondary packaging keeps all individual packs or bottles safe.

In short…

Both primary and secondary packaging protect the medicines from damage.

Here are examples of secondary packaging in the pharmaceutical industry:

1. Folding Cartons

Folding cartons are sturdy paper-based containers often used for secondary packaging in the pharmaceutical industry. Think of them like mini boxes, specifically designed to hold blister packs, bottles, or vials of medications.

Basically, they protect the contents. However, most businesses also use these containers for information dissemination, as the carton has enough space for important details like dosage instructions and expiration dates.

Folding cartons are eco-friendly because they are made from renewable materials like paperboard. This means less impact on the environment compared to plastic or metal alternatives.

And they are customizable, you can brand them with your logo and other essential information. Many brands agree that this is a smart way to promote businesses.

If you are looking for this type of packaging, we’d recommend FSC-certified folding carton manufacturers. Here is why.

2. Corrugated Boxes

These boxes are made of a combination of cardboard layers to offer reliable protection for your valuable products. Corrugated boxes are versatile and eco-friendly, too. That’s why they are widely used in the pharmaceutical industry.

Similar to most secondary packaging options, corrugated boxes provide excellent protection for pharmaceutical products during transportation and storage.

What’s more, the durable design ensures your valuable medications remain safe from damage or contamination. Corrugated boxes are usually lightweight, which helps you save money on transportation as well as storage.

3. Pouches and Bags

Secondary packaging for some pharmaceutical companies sometimes includes pouches and bags. These are just containers made from eco-friendly materials (mostly paper or biodegradable plastics).

Pouches and bags ensure the safety and integrity of pharmaceutical products during storage and transportation. They safeguard the potency of the drug and also prolong its shelf life.

Branding is the next reason why this type is gradually becoming popular. The flexibility in design allows for creative branding. So what we are saying is that this option can help you distinguish your products on the market.

4. Wallets

Everyone has seen a wallet. But in pharmaceutical packaging, it may mean a slightly different thing.

Wallets are compact containers that are designed to hold blister packs or other primary packaging securely. They protect medications from external elements and physical damage.

As they are typically made from recyclable paperboard or biodegradable plastics, these packages are lightweight and sustainable.

The benefits include:

- It makes it easier to transport products

- Reduces waste and environmental impact

- Allows you to showcase your company logo and product information prominently

- Saves space on the shelf

What Material Properties are Important in Pharmaceutical Packaging?

Here are the material properties that are key in pharmaceutical packaging:

1. Chemical Resistance

Pharmaceuticals are generally sensitive to outside elements. In this regard, exposure to certain chemicals may alter their effectiveness or even lead to contamination.

This is why you must pay attention to chemical resistance, simply to ensure that the packaging material doesn’t react with the contents.

Imagine investing time and resources into developing life-saving medications, only to have them compromised by subpar packaging. Not an option, right? For this reason, going for packaging with excellent chemical resistance is non-negotiable.

2. Sterilization

When bacteria, viruses, or other harmful microorganisms contaminate pharmaceuticals, they might jeopardize patient health.

This makes sterilization very important. And various packaging materials respond differently to sterilization processes.

For instance, some materials may withstand the high temperatures required for autoclaving, while others may degrade or release harmful substances under such conditions.

You must understand how different materials react to sterilization to pick the most sustainable pharmaceutical packaging option.

3. Durability

This property is what ensures your products remain safe and intact throughout their journey from manufacturing to the hands of the consumer.

Think about it. You put a lot of effort into creating high-quality medications, so it only makes sense to protect them with packaging that can withstand the rigors of transportation and handling.

4. Transparency

Clear packaging in the pharmaceutical industry allows you to visually inspect the contents without opening it. This may also mean greater confidence in your product’s quality.

When customers can see the medication they are about to use, it builds trust. Moreover, transparency expedites inventory management, reducing errors.

But it’s not just about function. Transparency is about sustainability, too. Most clear packaging is recyclable. This contributes to your eco-friendly initiatives.

5. Barrier Properties

Barrier properties refer to the ability of packaging materials to protect pharmaceutical products from external influences such as moisture, oxygen, light, and contaminants. Essentially, they are the ones who ensure your products reach customers safely.

Oxygen causes oxidation that renders medicines ineffective, while moisture can lead to degradation or contamination. So when you select packaging materials with excellent barrier properties, you are ensuring that your pharmaceuticals reach the end user in perfect condition.

Materials such as aluminum foil and certain plastic materials are preferred for their strong barrier properties.

Different Pharmaceutical and Packaging Material Options

Not every packaging material option is perfect for all pharmaceutical products. Each product requires specific packaging materials. This is largely due to the characteristics of the medicine and the properties of the packaging material.

Now we are going to state the characteristics of each type of product. Then give you a few packaging options that would suit them.

1. Tablets and Capsules

- Primary packaging: Bottles, blister packs

- Secondary packaging: Paperboard cartons

These are among the most common forms of pharmaceuticals, known for their convenience. The drugs mostly require packaging that offers protection against moisture, light, and tampering.

That is…

Tablets are usually composed of powders compacted into solid forms, while capsules consist of medicines enclosed in gelatin or vegetarian shells. Both need packaging that preserves their integrity and potency.

Bottles and blister packs check all the boxes if you are looking for primary packaging to safeguard tablets and capsules.

Besides protection, they provide tamper-evident features to assure your consumers of the product’s authenticity. And for secondary packaging, most companies prefer paperboard cartons for their versatility and eco-friendliness.

2. Liquid Formulations

- Primary packaging: Plastic bottles or glass

- Secondary packaging: Corrugated boxes or cardboard boxes

Syrups, suspensions, and other liquid formulations require packaging materials that ensure product stability and safety. Typically, these formulations contain active ingredients that may degrade when exposed to light or oxygen.

The packaging materials must offer protection against these elements. So, plastic bottles, especially those made from high-density polyethylene or amber glass, are the most commonly used due to their ability to block light and oxygen penetration.

But when it comes to secondary packaging, you should focus on materials that can act as a barrier against moisture, temperature fluctuations, and physical damage.

Corrugated boxes or cardboard cartons are the most common. They provide a surface for important labeling information to ensure clear communication to consumers. This, plus protection, makes boxes and cartons ideal as secondary packaging for liquid formulations.

3. Injectable Products

- Primary packaging: Glass vials or ampoules

- Secondary packaging: Cartons

These products often contain sensitive formulations that must be protected from contamination and degradation. For instance, vaccines demand packaging that prevents exposure to light, oxygen, and moisture to maintain their potency.

Glass vials and ampoules are generally used as the primary packaging because of their inert nature and ability to withstand sterilization processes. Cartons further offer protection during storage and transportation.

But the most important requirement here, other than protection, is compliance with regulatory standards by the FDA and EMA.

4. Powders and Granules

- Primary packaging: Glass bottles, sachets

- Secondary packaging: Cartons, boxes, or pouches

These present unique challenges in pharmaceutical packaging. They require protection from moisture, light, and contamination to maintain efficacy. So, the packaging should be:

- Moisture resistant

- Light blocking

- Chemically inert

- Meets regulatory standards

Pouches, cartons, boxes, and bottles are popular choices. They offer excellent barrier properties, prevent moisture ingress, and maintain product stability.

Also, they are widely accepted by regulatory bodies due to their compliance with pharmaceutical standards.

5 Tips to Keep Eco-Friendly Packaging in the Pharma Industry

Traditional packaging materials are known to contribute to environmental degradation through excessive use of non-biodegradable plastics.

This is why many brands are turning to eco-friendly packaging, because it offers an alternative that can minimize waste generation. These packages also align with the growing demand for sustainability.

As more and more consumers today prefer environmentally-conscious purchasing decisions, pharmaceutical companies must adapt to meet these expectations to maintain their market relevance.

The following sustainable packaging practices will help you ensure your packaging is eco-friendly.

1. Choose Materials that can be Easily Recycled

We’ve agreed that you need to consider the characteristics of the drug and its packaging to settle on the best packaging option. But while these are the primary concerns, the bottle, box, or container you use for packaging should be eco-friendly, too.

That is to say, if the medication is sensitive to light or moisture, the packaging protects it against those elements while still being eco-friendly.

Materials such as glass, aluminum, and certain types of plastics are the most commonly used for their recyclability. You should pick your option among these sustainable packaging solutions.

2. Keep Packaging Minimal to Reduce Waste

Less is often more. Achieving the level of protection you want requires using only a fraction of the packaging material you normally use. While it may not work for all products, it does for some.

You can reduce waste in the pharma industry just by going for minimal packaging.

Here is how it works:

Think about the less material used for packaging, the less ends up in landfills. Simple, right?

But it’s not just about less waste. Minimal packaging also means lighter shipments, which equals fewer emissions during transportation.

3. Look for Biodegradable Options to Help Nature

Biodegradable packaging materials break down over time to reduce the burden on ecosystems. So, by choosing these options, you are showcasing your support for environmental conservation.

And when this packaging degrades into organic matter, it enriches the soil and supports plant growth, which is a complete cycle.

4. Use Water-Based Inks

This type of ink is made without harmful chemicals such as volatile organic compounds and heavy metals, unlike traditional solvent-based inks. It’s mostly to minimize air pollution and safeguard the health of your workers.

Moreover, water-based inks are biodegradable, making them less harmful to ecosystems once disposed of. They also come in recyclable packaging, which completes the eco-friendly cycle.

So, by choosing water-based inks for your pharmaceutical packaging, you’re not just embracing sustainability. You’re making a responsible choice for the planet and future generations.

5. Pick the Right Packaging Supplier

The person who supplies your packaging of pharmaceutical products can make a massive difference in your sustainability efforts.

So, look for suppliers who offer recyclable plastics, biodegradable options, or even reusable containers. This environmentally-conscious packaging reflects positively on your brand. The right supplier can even use energy-efficient manufacturing processes to further reduce the carbon footprint.

Conclusion

Pharmaceutical packaging has undergone a remarkable transformation. Today, it’s about environmental sustainability just as it is about product protection. Each option brings us closer to a greener tomorrow.

Going eco-friendly doesn’t mean sacrificing quality or efficiency. Many sustainable packaging materials offer superior protection. Therefore, as you consider your packaging choices, know that every decision counts. We offer you an amazing solution for sustainable packaging.

Revolutionize Your Packaging With Packoi’s Eco-Friendly Solutions

Packoi is here to help your business with top-tier, innovative packaging solutions that meet your needs. So, are you ready to make a sustainable shift in your packaging? Contact us for a free sample today.