Last Updated on December 5, 2025 by Packoi Team

Understanding GSM and PT is important in printing & packaging as it helps companies to choose the optimal material for their needs. Businesses often find it hard to know which measuring unit to use when selecting the right paper.

In this article, we discuss the differences between GSM and PT in detail. It also provides a comprehensive guide on which unit is preferred throughout various industry applications. Let’s dive in.

What is GSM?

GSM stands for Grams per Square Meter, and is a unit of measurement to define the weight of paper and fabrics. It denotes the weight of a sheet of paper or fabric in grams, that is, one square meter in size.

This measuring technique determines the thickness, durability, and suitability of the paper for different applications. As paper can have different weights due to its composition, the GSM system provides a consistent way to compare paper weights and their quality.

For example, a 90 GSM sheet of copy paper is thinner and lighter than a 300 GSM piece of cardstock, even though they may feel similar in thickness.

This works by cutting a one square meter sample of paper and weighing it. The weight directly tells its GSM number, regardless of thickness or material composition.

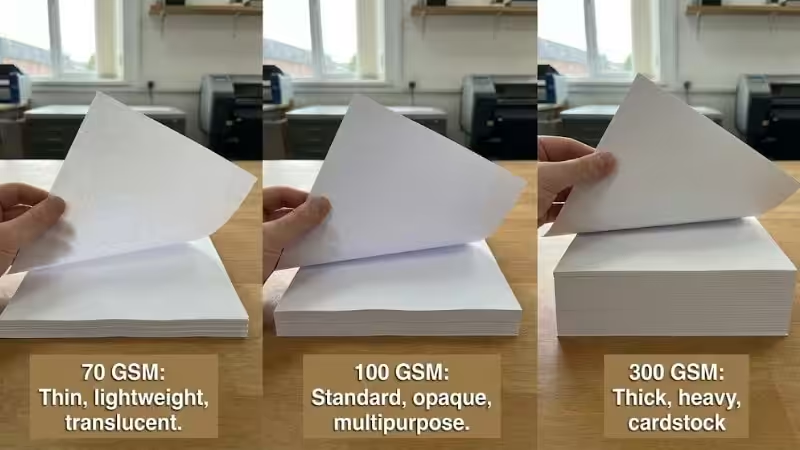

In the paper industry, common GSM ranges include:

- 35-55 GSM: Very thin paper used for newspapers.

- 70-90 GSM: Standard office copy paper for everyday use.

- 100-120 GSM: Heavier office paper for letterheads and envelopes.

- 120-150 GSM: Used for flyers, leaflets, and thinner posters.

- 300-350 GSM: Heavy cardstock for premium covers and durable packaging.

- 350-450 GSM: The thickest cardstock used for premium business and greetings cards.

Grams per square meter (GSM) is essentially the metric equivalent of the point system, as it uses centimeters and meters for its primary measurement.

What is PT (Points)?

The PT unit system is used to define the thickness of paper and cardstock in the printing and packaging industries. Unlike GSM, PT specifically measures thickness, regardless of weight or composition.

One point (PT) is equal to 1/1000th of an inch (0.001 inches or 0.0254 mm). For example, a 10 PT paper is 0.01 inches (0.254 mm) thick, while a 20 PT board is 0.02 inches (0.508 mm) thick.

Here’s how PT measurement works:

- A sample sheet is placed in a micrometer. A micrometer or screw gauge is an instrument used to measure very small distances.

- The micrometer measures the thickness of the paper in thousandths of an inch.

- PT value is then recorded. Each PT represents 0.001 inches of thickness.

Since the PT system measures thickness, the same value of PT can have different paperweights. For example, a 12 PT coated cardstock may feel lighter than a 12 PT uncoated recycled board because coatings and material compositions affect weight.

Typical PT values for industrial uses include:

- Business Cards: 14 PT to 32 PT for durability.

- Postcards and Invitations: 12 PT to 18 PT for a premium feel.

- Folding Cartons (Packaging): 16 PT to 24 PT to ensure rigidity.

- Retail Tags & Signage: 18 PT to 32 PT for long-lasting use.

GSM to PT Conversion Chart

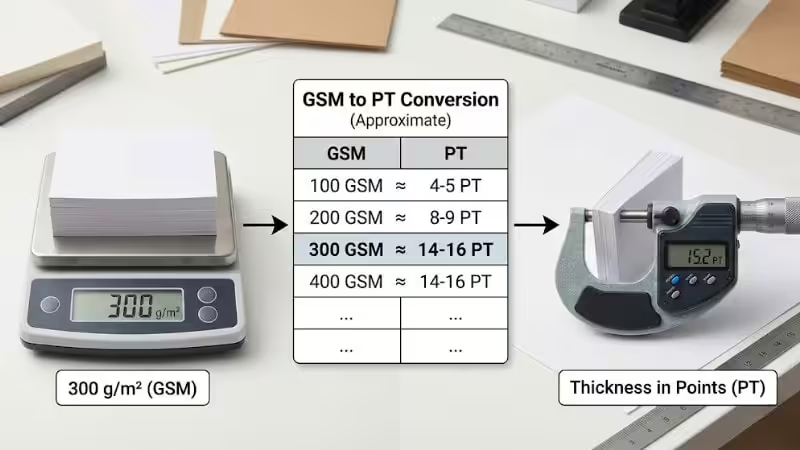

Both GSM and PT measure different aspects of paper, so there’s no exact one-to-one conversion of these units. Instead, approximate values can be used based on typical paper densities and compositions.

The following table shows GSM to PT conversions of common GSM paper measurements. However, these values are approximate and can vary based on paper type and manufacturing processes.

| Paper Type | Approx. GSM | Approx. PT | Thickness (Inches) | Common Applications |

|---|---|---|---|---|

| Newspaper | 35-55 GSM | 1.5 - 2 PT | 0.002" | Daily newspapers |

| Standard Copy Paper | 75-90 GSM | 3 - 4 PT | 0.004" | Office documents, assignments |

| Magazine Paper | 100-120 GSM | 5 - 6 PT | 0.005" | Magazine pages, letterheads |

| Flyer / Poster | 130-150 GSM | 7 - 9 PT | 0.008" | Leaflets, brochures, thin posters |

| Standard Cardstock | 250-300 GSM | 10 - 14 PT | 0.014" | Standard business cards, paperback covers |

| Premium Packaging | 350-400 GSM | 16 - 24 PT | 0.018" - 0.024" | Retail Boxes, Cosmetic Packaging |

| Heavy Board | 450+ GSM | 24+ PT | 0.024"+ | Rigid boxes, display stands |

These conversions are based on the following considerations:

- Paper Density: As GSM value increases, PT value also increases and vice versa. This is because increasing GSM value means increased paper thickness. However, coatings and materials can affect the actual thickness.

- Conversion Rate: A general rule is that every 50 GSM increase adds approximately 2-3 PT, though variations exist based on paper composition.

- Check Manufacturer Specifications: Always refer to actual product details because different paper manufacturers can have various coatings, laminations, and compositions of their paper that can influence thickness or weight.

Understanding these conversions can help companies make informed decisions on choosing the right paper for their packaging and printing needs.

Choosing Between GSM & PT for Your Business

GSM and PT are both important metrics to consider when measuring the weight and thickness of paper and cardstock. Both units are applicable in various contexts within the printing and packaging industries.

When to Use GSM?

GSM is used when the weight of the paper is a crucial factor. A higher GSM value in packaging means the material can withstand the weight of the product during transit and handling.

For printing purposes, a higher GSM value is preferred for better print quality, engravings, color vibrancy, and image quality. Lighter GSM papers can be used if a company is looking to lower its transportation costs.

When to Use PT?

PT is considered when the thickness of the paper is a primary concern. Thicker materials (higher PT) are more rigid and durable, suitable for products that require sturdiness.

Customers prefer product packaging that looks and feels high-end. A thicker cardstock can convey a sense of luxury products.

Industry Applications

Both GSM and PT are significant in packaging. The following are some industry applications that either prefer GSM or PT for paper measurement:

- In post offices, lighter GSM papers are considered to minimize postage costs.

- For books and brochures, a balance between GSM and PT is essential as the inner pages use a moderate GSM for flexibility, while the cover uses a higher PT for protection.

- Business cards use a high PT for a professional look and increased durability due to excessive handling.

Factors Affecting Paper Weight & Thickness

The thickness and weight of paper are affected by factors like paper coating, lamination, and composition. Hence, GSM and PT values can vary based on these factors.

1. Coating and Lamination Impact

Applying certain coatings to the surface of a packaging material enhances its visual appeal and gives it a smooth, professional feel. Matte, gloss, and soft-touch text paper have their specific advantages, but they also make the paper feel stiffer and heavier, even if their base weight remains unchanged.

Lamination is the process of adding a plastic layer to the surface of the paper to provide extra protection against moisture, stains, wear, and also to give it a smooth, professional feel. This process increases both the thickness and weight of the paper.

2. Material Composition

Cardboard: Made up of multiple layers of paper and is generally used for packaging purposes. Its thickness and weight are significantly higher than standard paper.

Kraft paper: Made from chemical pulp produced in the kraft process. This is also used for packaging and wrapping, as it is heavier and thicker than standard paper.

Coating stock: Has a coating applied to its surface to improve qualities like brightness, smoothness, or gloss. The type of coating applied can change the weight and thickness of the paper.

How to Select the Right Paper for Printing & Packaging

Choosing the right paper for your packaging can affect your brand perception, quality, durability, and budget.

Branding, Durability, and Budget

Coated paper can affect the look and feel of a printed surface. Heavier and textured papers can convey a sense of luxury and quality.

The right packaging materials need to withstand frequent handling and transportation, hence one should consider thicker (higher PT) and heavier (higher GSM) papers for this purpose.

However, heavier and thicker papers generally cost more. Balancing packaging costs is crucial for a business. Businesses should weigh the pros and cons of using premium-quality paper.

Real-World Examples of GSM vs. PT in Different Industries

The following are examples of standard GSM and PT values that various industries use:

- In the packaging industry, companies use 350 GSM paper with a thickness of 22-24 PT to ensure durability during handling and a premium feel for better marketing.

- Standard business cards often use paper around 300 GSM with a thickness of 14-16 PT.

- For booklets and brochures, 130 GSM bond paper (9-10 PT cover stock) is used for flexibility, while covers use 200 GSM (11-12 PT) paper for protection.

- Text-heavy publications like dictionaries and religious books use thinner printer paper of 30-50 GSM (2-3 PT).

FAQs

Q1: Is 14pt or 16pt paper thicker?

16pt paper is thicker than 14pt paper. The higher the point (PT) value, the thicker the cardstock. 16pt is often used for premium business cards or luxury packaging inserts.

Q2: How do I measure paper thickness without a micrometer?

While it’s hard to be exact, you can compare it to known items. Standard copy paper is about 3-4 PT. A standard business card is about 14 PT. A credit card is roughly 30 PT.

Q3: Does higher GSM always mean higher thickness?

Generally, yes. However, a dense, uncoated paper might have a high GSM (weight) but be thinner than a bulky, porous paper with a lower GSM.

Conclusion

Understanding when to use the right paper measuring unit is crucial in the printing and packaging industry. In this article, we provide insights into how GSM and PT are used to measure the weight and thickness of paper, respectively.

Our GSM to PT conversion table also comes in handy when choosing the proper weight and thickness for specific industry applications like packaging, printing, publications, cards, etc.

By understanding the intricacies of GSM and PT values in measurement, packaging designers can create high-quality and cost-effective products.

Choose the Perfect Paper for Your Packaging & Printing Needs at Packoi

Looking for the perfect paper for your printing or packaging needs? At Packoi, we bring years of expertise in helping businesses worldwide to find the best custom packaging solutions.

Whether you need durable packaging, gift boxes, or custom marketing materials, selecting the right paper impacts design, cost, and quality.

Still not sure if you need 14pt or 18pt? Our experts guide you through considerations of weight, thickness, and cost. Contact us now to find the ideal paper for your next project!