Last Updated on April 16, 2025 by Packoi Team

Have you ever noticed designs on packaging that feel raised to the touch or indented into the surface? That’s the magic of embossing and debossing! These finishing techniques make designs stand out and give products a premium, tactile appeal.

In this guide, we’ll explain embossing and debossing, highlight their differences, and explore some common techniques used in these processes. We’ll also share key considerations to help you choose the perfect technique for your product.

What are Embossing and Debossing in Packaging?

Embossing involves pressing a design from the back of a material so that it pops out on the front surface. This is achieved by sandwiching the material between a raised design (male die) and its recessed counterpart (female die). Embossing is commonly used to highlight logos, brand names, or intricate designs.

Debossing is quite the opposite of embossing. In debossing, the design is pressed into the surface, creating an indentation on the front side. Typically, only a female die is used to create the desired depression. Debossing is often chosen for its subtle, minimalistic aesthetic appeal.

Embossing vs. Debossing: A Side-by-Side Comparison

Embossing and debossing are widely used design techniques for adding visual appeal to products, packaging design, and printed materials. While both aim to add a touch of luxury, they differ in execution, effect, and other characteristics.

The table below gives a detailed comparison of embossing and debossing, highlighting differences in their design effect, visual effect, cost, durability, process complexity, and common applications.

| Characteristic | Embossing | Debossing |

|---|---|---|

| Design Effect | Raised design elevated above material’s surface | Recessed design indented into the material |

| Visual Effect | Bold, prominent and eye-catching designs | Clean, subtle, and sophisticated designs |

| Cost | Slightly more expensive due to the use of two-part die. | Cheaper as it typically uses a plastic plate. |

| Durability | Raised areas are more prone to wear and tear. | Indented areas are more durable, because of the protection by surrounding material. |

| Process Complexity | Requires both male and female die. | Requires only female die. |

| Examples | Logos on luxury packaging, wedding invitations, etc. | Minimalistic designs, leather wallets, tags, notebooks, etc. |

3 Popular Embossing and Debossing Techniques Used By

Embossing and debossing are versatile techniques used across various applications in custom packaging, from luxury packaging to professional business cards. Some applications require a sleek, minimal texture, while others need a bold, eye-catching finish.

Depending on the application, designers use different methods to achieve unique visual effects and finishes.

In this section, we’ll explore three popular design techniques used in embossing and debossing, explaining what they are, how they differ, and where they are commonly used.

1. Blind Embossing and Debossing

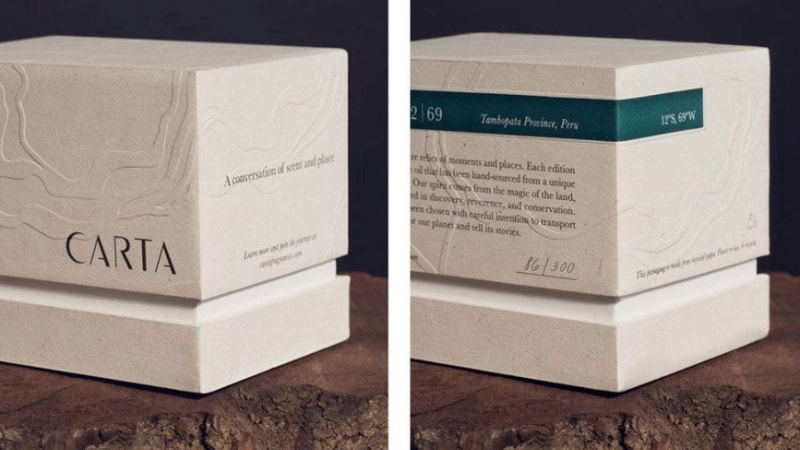

Blind embossing or debossing involves creating an embossed (raised) or debossed (depressed) design on a material without using ink or foil. In blind embossing, the material itself forms raised surfaces or depressions. When blind debossing is applied over a larger area, it is often called plate sinking.

The results of blind embossing or debossing vary depending on the embossing paper, cardstock, or the type of packaging. It generally results in a very subtle, sophisticated effect that gives a premium look. This technique is widely used for business cards, luxury shipping boxes, book covers, and certificates.

2. Foil Stamping

Foil stamping is a technique that uses heat and/or pressure to apply a thin layer of foil onto the material. It creates a shiny, metallic finish on the embossed or debossed design using a metal plate, adding texture and a luxurious touch.

Foil-stamped image is ideal for high-end products like perfumes, cosmetics, diploma certificates, seals, and logos, where a shiny or polished appearance is desired.

While the terms foil stamping and hot foiling are often used interchangeably, “foil stamping” also includes cold foiling, a process that uses adhesive and UV light instead of heat.

Heat embossing is another process similar to foil stamping. While foil stamping uses heat and pressure to transfer metallic foil, heat embossing involves embossing powders and heat to create a raised, textured design to create a raised, textured design without using metallic foil.

3. Multi-Level Embossing/ Debossing

Multi-level embossing or debossing is an advanced technique that creates designs with varying levels of depth, where some parts of the design are raised or recessed more than others. It is achieved by using multiple custom dies with various depths.

With some parts popping out more and others sitting down, multi-level embossing or debossing gives a more sculpted, 3-dimensional look. It looks like the design has been carved or molded. This technique works well for eye-catching and complex designs, such as in premium event invitations, designer clothing tags, leather handbags, and custom trophies and awards.

Key Considerations For Embossing & Debossing

If you are planning to use embossing or debossing for your next print project, it is important that you are aware of all the essential design considerations beforehand. This includes choosing the right type of design, design file, design placement, and paper type.

Understanding these points will help you achieve your desired results and avoid any surprises along the way.

1. Selecting the Design

Selecting the right design is the foundation of successful embossing or debossing. It is best to go for simple designs, as overly complex patterns may translate poorly onto the material. If it includes text, use fonts with clean edges and appropriate spacing.

2. Converting the File Type

Always ask your designer to provide the final artwork as a vector file, such as AI, EPS, or SVG, to ensure flawless embossing or debossing. Unlike raster files (like JPG or PNG), vector art is built on mathematical calculations, allowing it to be resized up or down without losing quality.

3. Deciding Design Placement

With strategic design placement, you can enhance the design’s visual appeal. Choose an area strong enough to withstand embossing or debossing. If there are any other design elements, ensure that the design aligns with them. Avoid placing the design near any folds, creases, or edges, as this might distort the embossed image.

4. Choosing the material

Selecting the right material is crucial for embossing or debossing. The most commonly used materials include paper, cardstock, leather, and textiles.

For paper embossing or de-embossing, it is recommended to opt for heavier paper stock, as thin or lightweight paper may not be able to bear the pressure applied by the embossing machine. A smooth surface would be ideal if you want to achieve a sharp imprint.

Top 3 Benefits of Embossing and Debossing

In this section, we’ll focus on some major benefits of embossing and debossing that will help you with choosing the best packaging for your business.

1. Increased Visual Appeal

Both finishing techniques, embossing and debossing, add a luxurious feel to your product, making the design stand out. The recessed or raised effects draw attention and create a memorable experience for the consumers.

2. Sensory Experience

An embossed or debossed image presents sensorial cues to the customer, evoking an emotional response. This tactile experience makes the product more interactive, increasing the chances of buying it.

3. Brand Differentiation

Unique and creative designs help a brand stand out among its competitors. Embossed or debossed elements add uniqueness to the design, making customers naturally drawn to the product.

How to Choose Between Embossing and Debossing For Your Product?

When choosing between the embossing and debossing process, the primary considerations include the effect you want to create, the material you wish to use, and how much you are willing to spend.

1. Visual Effect

To select between embossing and debossing, ask yourself: What effect do I want?

If you desire a minimalistic, subtle appearance without too many details, debossing is the way to go; however, if you want a prominent, bold, eye-catching look with intricate details, then choosing embossing is a better idea.

2. Material

The embossing process works best on thicker, sturdier materials such as leather, heavy card stock, and thicker plastics. If the material is too thin, it may tear or puncture, as the design process involves pressing material between male and female dies.

The debossing process, on the other hand, works well with slightly more flexible materials, such as paper, fabrics, and thin plastics. The flexibility allows for creating clean indents without damaging the structure.

3. Cost Considerations

Debossing typically requires only one die, making it a more cost-effective option compared to embossed packaging, which uses two dies.

Frequently Asked Questions (FAQ)

1. What is the difference between embossing and debossing?

Embossing creates an elevated design on the material raised from the surface, while debossing creates a depressed design indented into the surface.

2. Can embossing and debossing be combined?

Yes, embossing and debossing can be combined to create a multi-dimensional look with some parts raised and some recessed on the same surface.

3. What materials are best for embossing or debossing?

Thicker and smooth materials like cardstock and leather are ideal for embossing, while materials with a bit of flexibility, such as paper, fabric, and thin plastics, work well for debossing.

Conclusion

In this comprehensive guide, we outlined the differences between the two popular finishing techniques, embossing and debossing. We also discussed the techniques used for both and important points to consider when opting for these procedures.

Now that you have a better understanding of when to use which technique, you’re all set to select the technique that suits your desired outcomes.

Get Premium Finishing For Your Designs At Packoi

Looking for a reliable supplier? Packoi is your trusted partner for creating stunning designs that leave a lasting impression and add elegance and sophistication to your packaging. Contact us now to order.