Last Updated on October 27, 2025 by Packoi Team

Choosing materials for frozen food packaging isn’t a one-size-fits-all process. Factors like moisture control, temperature resistance, and shelf appeal all play a part in how a product performs. Some materials offer better protection against freezer burn, while others focus on reducing waste or improving recyclability.

This guide looks at the materials, designs, and solutions that keep frozen foods intact and appealing, from production lines to grocery shelves. Let’s get started.

Key Considerations: A Quick Guide for Your Business

Before discussing materials and design solutions, it helps to step back and look at the essentials. Frozen food packaging has to do more than look good. It must protect, preserve, and perform under extreme conditions.

The following factors come into play:

- Temperature Resistance: The packaging must hold up in freezing environments without splitting or losing shape.

- Moisture and Air Control: A solid barrier prevents ice crystals, freezer burn, and flavor loss.

- Material Selection: Plastic films, coated paperboard, and foil are common choices. Each works best with certain food types and storage methods.

- Seal Strength: Weak seals lead to leaks and contamination, shortening product life.

- Environmental Responsibility: More brands are shifting toward recyclable or compostable packaging to cut waste and appeal to eco-conscious buyers.

These points form the foundation of good packaging design. The next sections take a closer look at the materials and technologies that make those standards possible.

Why is High-Quality Frozen Food Packaging So Important?

Ever wonder how your frozen favorites, like frozen vegetables and ice cream, stay fresh, flavorful, and ready to enjoy after months in the freezer?

The secret lies in their frozen food and packaging process. This isn’t just about wrapping up food; it’s an art that ensures taste, nutrition, and convenience are locked in, ready for your next meal.

The right frozen food packaging does more than just store your food; it plays a crucial role in maintaining food quality, ensuring food safety, and reducing food waste. A study from the American Frozen Food Institute highlights that nearly 40% of all food in the U.S. is wasted, with a significant portion of this loss preventable through better packaging solutions.

Frozen food packaging is designed to withstand extreme cold, keeping the contents inside safe from freezer burn and contamination, which can degrade the food’s taste and nutritional value.

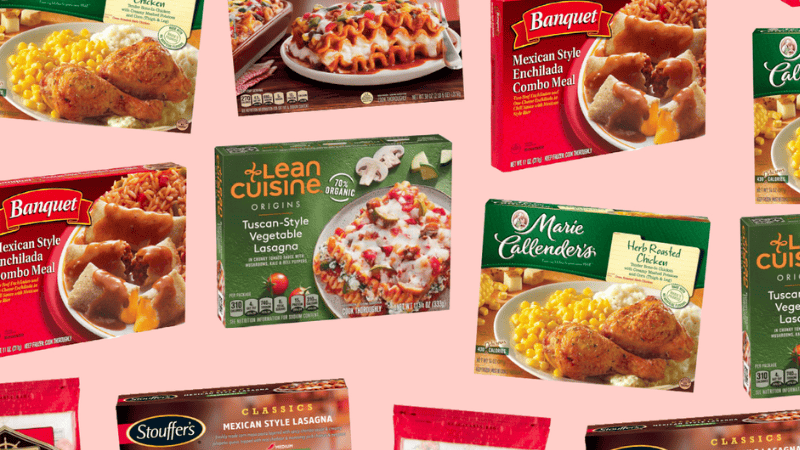

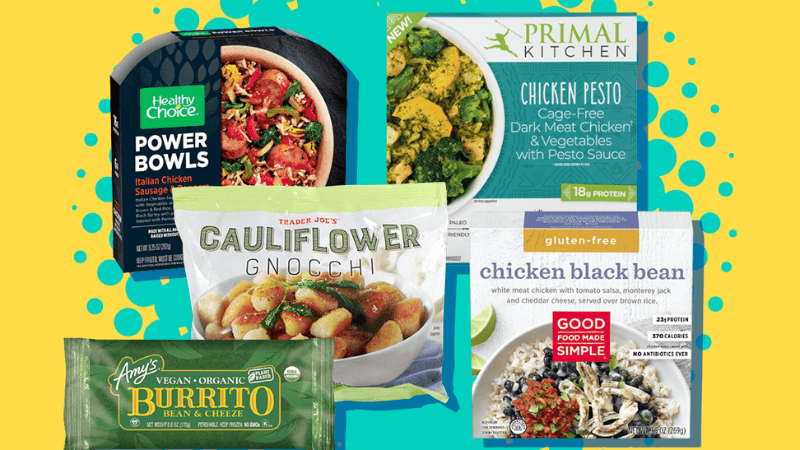

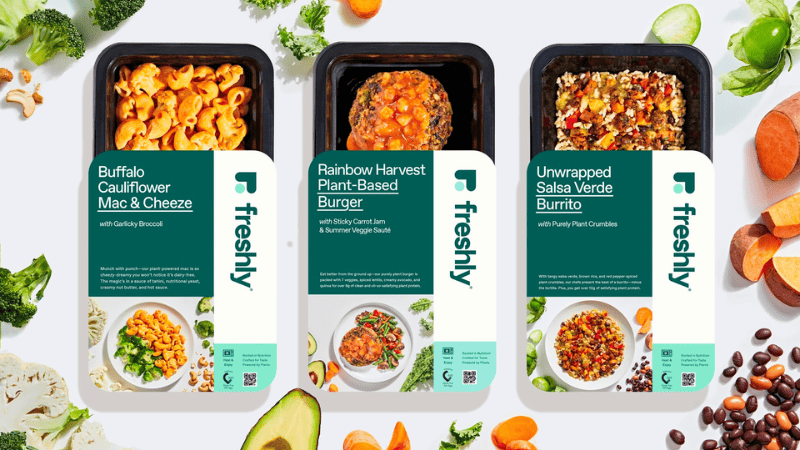

Moreover, this packaging is the first thing consumers see, acting as a silent salesman that communicates the brand’s promise and the quality of the product inside. Vibrant, high-quality printing on a custom pouch grabs attention and communicates your brand’s quality.

In a crowded frozen food aisle, the visual appeal of frozen food packaging can set a product apart, making it more likely to end up in shoppers’ carts.

From a logistical perspective, effective packaging is essential for transporting and storing frozen foods. It ensures that products can be efficiently stacked, stored, and shipped without damage, maintaining the integrity of the food through every step of the supply chain.

The development of innovative packaging materials and technologies has also allowed for an extended shelf life of raw food, reducing the need for preservatives and offering consumers fresher-tasting food.

More importantly, modern packaging includes features like resealable zippers, microwave-safe trays, and easy-open tearing, making the product more convenient and increasing the chance of a repeat purchase.

8 Key Factors to Consider When Choosing Frozen Food Packaging

Choosing the right packaging for frozen food isn’t just about keeping it cold; it’s a complex decision with many layers. Here’s what to keep in mind to ensure your products stand out for all the right reasons.

1. Barrier Protection (Moisture & Oxygen)

Essential for preventing food spoilage and extending shelf life, adequate barrier protection blocks out moisture, cold air, and contaminants. This same sealing technology is critical for maintaining the quality and safety of frozen food products.

2. Durability at Low Temperatures

Packaging must withstand freezing temperatures without cracking or losing integrity. Frozen food packaging materials must be robust to handle frozen products’ freezing and subsequent thawing.

3. Seal Integrity

A strong seal prevents ice crystals from forming inside the package, which can lead to flavor and texture changes. Properly sealed frozen food packaging ensures the food product remains fresh and appealing.

4. Microwave and/or Oven Safety

Food packaging must safely heat frozen meals and foods that move from the freezer to the microwave or oven. Materials like aluminum foil and certain plastic films are designed for this purpose, offering food safety and convenience.

5. Product Visibility & Aesthetics (e.g., a clear window)

Visual appeal plays a huge role in consumer choice, especially in the crowded frozen food aisle. Packaging that offers a clear view of the frozen food inside, along with an attractive design, can significantly impact buying decisions.

6. Consumer Convenience (e.g., easy-open, resealable)

Features like easy-open frozen packaging, resealability, and microwave safety add value for consumers, making frozen food products more appealing. Flexible packaging options, such as stand-up pouches, often include these consumer-friendly elements.

7. Cost-Effectiveness

While quality is paramount, frozen food manufacturers must also consider the cost of packaging materials. Balancing high-quality plastic packaging materials with affordable solutions ensures that the product remains competitive without compromising protection or appeal.

8. Eco-Friendliness & Sustainability

Consumers increasingly seek packaging that aligns with their values, including environmental sustainability. Options like recyclable plastic containers, biodegradable plastic films, or wax-coated paper can enhance the brand’s image of environmental sustainability and appeal to eco-conscious buyers.

Best Packing Materials for Different Frozen Food Products

Undoubtedly, selecting suitable packaging material is crucial for frozen food manufacturers. Let’s dive into the optimal materials that safeguard against food spoilage and enhance visual appeal, ensuring products withstand freezing and maintain storage life.

1. Flexible Packaging for Frozen Meats, Seafood, Fruits, and Vegetables

Made from layered plastic films (like PE or PET), these are the most popular choice for frozen vegetables, fruits, and seafood. Offering off-season availability and convenience, frozen fruits and vegetables need clear, robust packaging to safeguard their nutritional content and visual appeal.

Packaging solutions that protect from cold air fluctuations are essential, ensuring these perishable goods remain as nutritious and tasty as their fresh counterparts.

Their pros include:

- Strong Barrier Protection: They keep out moisture and oxygen to prevent freezer burn and flavor loss.

- Lightweight Construction: These bags reduce storage and shipping costs while maintaining product safety.

- Resealable Options: Zippers or seals help keep food fresh after opening.

- Printable Surface: The bags allow clear branding, product images, and instructions without added labels.

- Cost Efficiency: They use less material than rigid packaging, making it a budget-friendly option for large-scale production.

Flexible packaging, including stand-up pouch options made from plastic film, also offers convenience for frozen snacks and desserts like ice cream, which are popular for their resealable features and lightweight nature.

Advanced frozen food packaging materials like plastic films and vacuum-sealed bags are key to keeping these items in prime condition by guarding against ice crystals and preserving texture and flavor.

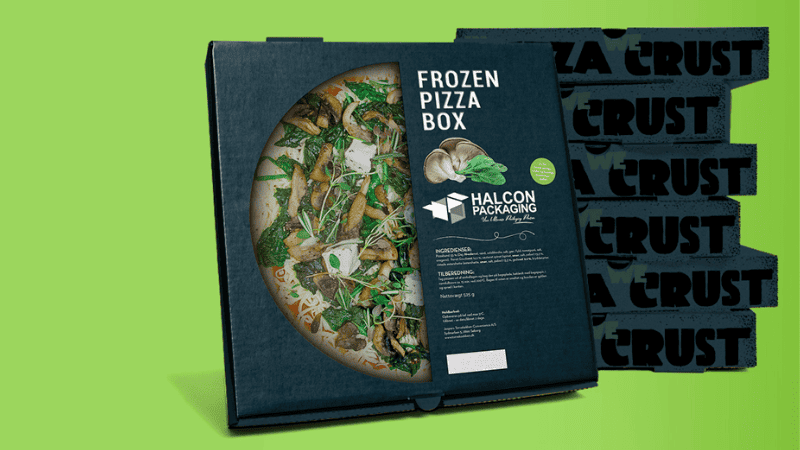

2. Paperboard and Cardboard for Ready-to-Eat Frozen Meals and Pizzas

Paperboard is ideal for frozen meals, pizzas, and baked goods. It’s often coated with a thin layer of PE plastic to act as a moisture barrier. Packaging that displays nutritional information, heating instructions, and food safety guarantees is crucial.

Diverse in toppings and crust styles, frozen pizzas benefit from packaging that locks in freshness while showcasing the product’s quality through vibrant packaging designs. Cardboard boxes with protective plastic film overlays can keep the pizza safe from freezer elements while tempting consumers with visuals of the delicious meal inside.

The pros of paperboard and cardboard in this regard include:

- Strong Structural Support: They hold their shape well and protect food from crushing during transport or stacking.

- High Print Quality: The materials provide a smooth surface for detailed graphics and branding, helping products stand out on shelves.

- Recyclable Material: The materials are easily processed through recycling systems, making them a more responsible choice for frozen food packaging.

- Customizable Design: They can be cut, folded, and coated to match different food types and temperature needs.

3. Rigid Plastic Containers for Frozen Desserts

From sorbets to ice creams, frozen desserts require enticing packaging that captures the richness and variety. Packaging designs that combine aesthetic appeal with functionality, such as resealable lids or easy-open wrappers, help maintain product integrity and stimulate repeat purchases.

The benefits of this packaging type are as follows:

- Reusable Construction: Consumers can reuse containers for storage, which adds convenience and reduces waste.

- Secure Resealing: Tight-fitting lids keep frozen foods protected after opening and prevent spills or contamination.

- Excellent Impact Protection: The sturdy build shields contents from crushing or damage during transport and handling.

- Clear Visibility: Transparent plastic lets shoppers see the product inside, boosting confidence in freshness and quality.

- Temperature Stability: These containers stay durable and crack-resistant even under freezing conditions.

Rigid plastic materials are chosen for their durability and clarity, making them excellent for packaging frozen food items, fruits, and ice creams, allowing consumers to see the frozen packaging contents while offering protection against impact.

4. Aluminum Foil & Trays for Frozen Baked Goods and Dough

This category extends from bread and pastries to pizza dough and pie crusts, all requiring packaging that prevents drying out and food spoilage. Aluminum foil and trays are often utilized here to preserve the taste and texture of these frozen food products as if they were freshly baked.

Their pros include:

- Even Heat Conduction: Aluminum spreads heat uniformly, helping frozen meals cook evenly in the oven.

- Complete Barrier Protection: It blocks moisture, air, and light, keeping food fresh and preventing flavor changes.

- Oven Compatibility: These trays can move directly from freezer to oven without warping or melting.

- Recyclable Material: Most aluminum trays can be recycled after use, supporting cleaner waste management.

- Lightweight Strength: Despite being thin, aluminum maintains strong protection against punctures and pressure.

With excellent thermal insulation, aluminum foil is suited for frozen meals transitioning from freezer to oven, maintaining even cooking temperatures, and preventing food spoilage.

5. Wax-Coated Paper for Frozen Meat and Seafood

This segment of the frozen food packaging industry includes a variety of proteins, such as beef, poultry, and fish, all of which require packaging that can withstand freezing temperatures while preventing food spoilage.

A traditional material for “butcher’s wrap” is often used for individual portions of frozen meat or fish. Its benefits include:

- Effective Moisture Barrier: The wax layer helps retain freshness by keeping moisture inside and blocking freezer air.

- Easy to Wrap: Its flexibility allows quick wrapping of meats, fish, or dough without tearing.

- Affordable Option: Wax paper offers reliable protection at a lower cost than many plastic alternatives.

- Freezer-Safe Surface: The coating prevents food from sticking, making it easy to separate portions after freezing.

- Lightweight Material: It adds minimal bulk while still guarding against short-term freezer damage.

This packaging provides a wax-coated paper barrier that withstands temperature and keeps moisture in while freezing, ensuring the frozen product doesn’t become cold water soggy.

How to Create Your Custom Frozen Food Packaging (A 5-Step Guide)

Crafting custom packaging for your frozen food lineup is a strategic move toward branding excellence and fostering a stronger connection with your clientele. Here’s a guided walkthrough to meticulously tailor your frozen food packaging, ensuring it resonates with both your brand ethos and your products’ unique requirements.

Step 1. Define Your Packaging Requirements

Begin by assessing the specific packaging requirements based on the frozen products you sell. Whether it’s meat products requiring robust barrier protection or frozen vegetables needing clear visibility, understanding these nuances is key to maintaining the quality and extending the storage life of your offerings.

Step 2. Choose Your Material and Format

The frozen food types in your catalog must inform the choice of packaging material. For instance, plastic and shrink films might be ideal for items requiring flexible, airtight sealing. In contrast, rigid plastic materials or cardboard boxes could better serve frozen pizzas or meals that benefit from sturdier support.

Step 3. Partner with an Expert Manufacturer

Partner with a manufacturer like Packoi, which not only brings a diverse array of plastic packaging materials and options to the table but also has a deep understanding of the frozen food market. Their expertise should align with the types of frozen food packaging materials you offer, whether that involves polyethylene film for food-grade safety or aluminum foil for oven safety.

Step 4. Design and Prototype

The design process should consider the specific packaging of the frozen food products you aim to package. A design that enhances the visual appeal of a custom package of your frozen meals can influence repeat purchases. It’s about marrying brand identity with the practical packaging needs of your product range.

Before finalization, test prototypes with a selection of your frozen food products to ensure the first packaging solution effectively meets the demands of freezing temperatures and transportation, safeguarding against food spoilage and ensuring food safety.

Step 5. Finalize and Launch

With all elements—from material selection to design specifics—tailored to the frozen food you specialize in, finalize the details with your packaging manufacturer. Ensure your launch plan maintains your frozen food’s integrity and visual appeal throughout the supply chain.

FAQs

Q1: Why does frozen food packaging need special materials?

Frozen food packaging must resist cold temperatures, block moisture and air, and prevent freezer burn while keeping the product’s flavor, texture, and appearance intact.

Q2: What’s the most eco-friendly packaging for frozen products?

Recyclable paperboard and compostable plastics are becoming popular options since they reduce landfill waste while maintaining durability and protection in cold storage.

Q3: Why do some frozen foods use both cardboard and plastic?

Combining materials balances, protection, and presentation. Plastic protects against moisture, while cardboard offers structure and space for branding or cooking details.

Conclusion

Frozen food packaging does more than protect products; it preserves taste, quality, and trust. The right material, seal, and design keep food safe across storage and transit while reflecting brand responsibility. As frozen food demand grows, smart packaging choices will define which products stand out in a crowded freezer aisle.

Discover the Perfect Solution for Your Business with Packio

For businesses looking to dive deeper into the world of frozen food packaging or seeking innovative solutions tailored to their unique needs, Packoi is here to help. With a wide range of services, from custom packaging solutions to expert design services, we’re equipped to bring your packaging vision to life.

Ready to transform your packaging from functional to phenomenal? Discover more about our capabilities at Packoi, start crafting your unique packaging by exploring our design services, or contact us directly. Let Packoi be the catalyst for your brand’s success in the frozen food aisle.