Last Updated on February 27, 2025 by Packoi Team

It has become an indispensable tool in print shops. Ultraviolet printers use technology that adds sophisticated printing interactions more effectively.

UV printing applies to advertisements, exhibition displays, furniture, tile production, home decoration, the glass industry, leather and textiles, cardboard packaging, mobile phone covers, and more.

In this blog, we will define UV printing, compare it against other printing methods, look at its various components and advantages, and then guide you in choosing the best UV printer for your print solutions.

This article aims to provide an in-depth overview of UV printing and its comparison to other printing techniques while describing the best practices to help you get started and learn about UV printing.

What is UV Printing?

UV printing is a form of printing that instantly cures specially formulated UV inks on a wide range of printing materials using ultraviolet light. This form of printing creates amazing print quality and high-impact printing applications more efficiently.

For UV printing to be successful, some essential properties and components are involved. These include print heads, motors, sensors, and the curing system.

What Are UV Ink, UV Light, and UV Printer?

- UV Ink – is an ink used in UV printing and is specially prepared to cure when exposed to UV light instead of air.

- UV Light – refers to a form of electromagnetic radiation consisting of 10 percent of the total radiation from the sun. This type of radiation is used in UV printing to cure ink on printing materials and surfaces.

- UV Printer – a printing machine that uses UV technology to print custom images or texts directly on a wide range of product surfaces or materials. There are many UV printers with different specifications and usage.

The UV Printing Process and Print Head

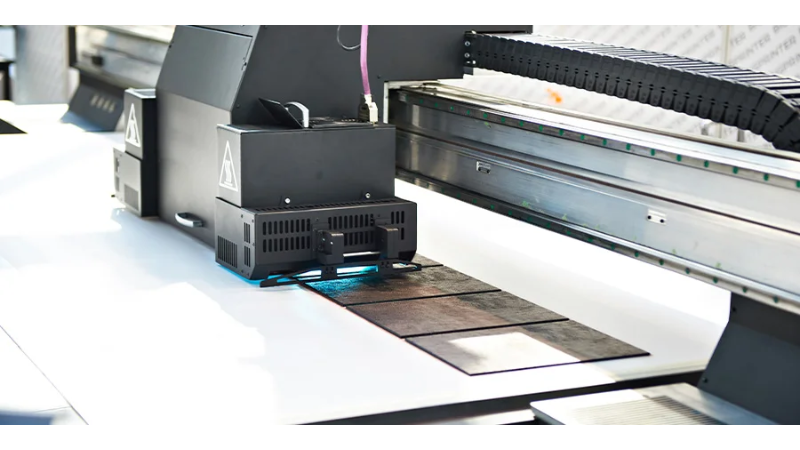

- The ultraviolet printing process involves the UV printer distributing UV ink on the material surface “substrate” through the print head nozzles, and as the printer distributes the ink, ultraviolet light follows closely behind, instantly curing and drying the ink.

- Print heads provide high-precision ink placement with piezo print head technology attached behind the print head nozzles, which is responsible for determining print quality. The numerous tiny nozzles use the mounted technology, systematically ejecting precise quantities of tiny ink droplets on the substrate to form an image.

The Significance of UV Printing in Today’s Printing Industry

As technology advances rapidly, some people probably think the printing industry has been left behind, especially with the popular rise of social media. But the printing world is still significant as technology fuels it, and we are not letting this industry fall back.

With the constant rise in print use in various industries, more efficient print technology is needed. Among other methods, UV printing has emerged to offer efficient solutions, and it has become one of the most popular methods that businesses are adapting to gain a competitive advantage.

UV printing technology is a rising trend in the print industry thanks to its flexibility, amazing print quality production, efficiency, and environmental benefits. It has replaced other conventional methods and pad printing.

With its exciting print processes, components, and properties, adapting UV print technology can significantly set you apart from other players in the industry.

5 Advantages of UV Printing Technology

1. Instant Curing

One of the key advantages of UV technology is that ink curing is instant as the droplets touch the substrate. Unlike other traditional printing methods, UV print has no degassing or drying as the ink is dried instantly. Ultraviolet light from built-in UV lamps in UV printers cures inks instantly, making the process faster and more efficient.

2. Enhanced Durability and Scratch Resistance

UV printing produces some superior-quality prints that are durable and resistant to scratching and fading. Because of the proven durability of its superior prints, UV printing is more popular with advertising agencies than traditional printing methods.

3. Vibrant and High-Quality Color Reproduction

The instant drying of inks in UV printing means that UV inks have no time to spread on the printed substrate. As a result, UV technology produces sharp, high-quality prints with outstanding gloss from vibrant colors. This is one of the reasons why advertising agencies, sign makers, and graphic providers embrace UV technology in their industries.

4. Versatility in Substrates and Applications

UV printing comes in handy for many applications. UV technology can be used in many industries, such as tile decoration, wood, advertisement banners, glass decoration, product personalization, printing packaging prototypes, and more.

This is one of the most versatile technologies, allowing printers to produce interactive images on almost all surfaces using UV-cured ink. There are many materials or substrates where you can print your desired image, like plastics, glass, metals, wood, paper, ceramics, textile fabrics, and more, depending on your needs.

5. Environmental Benefits

Another interesting benefit of UV printing is its environmental impact. Perhaps this is one of the driving factors for adapting UV technology as more and more businesses become environmentally responsible and promote eco-friendliness.

Unlike solvent inks in traditional printing methods that require oxidation to dry while releasing volatile compounds, UV printing produces less hazardous waste and volatile organic compounds (VOCs) as UV inks are instantly dried.

UV Printing vs. Digital Printing

Sometimes, people confuse UV and digital printing. The two methods have some similarities but have noticeable differences that set them apart. Ultraviolet printing is a specific digital form of printing but much more sophisticated than the others.

The UV printing process is very similar to that of digital printing. Both use advanced technology to produce results. But there are many differences.

Differences between UV Printing and Digital Printing

The primary difference between the two methods is printing ink and drying. Digital printing refers to methods that use computers to create design and print the digital design on a media substrate using UV curing for inks or laser in toner-based printers. For digital printing, if you want to know more, you can deepen your understanding by reading the comparison between offset printing and digital printing.

UV technology specifically uses UV light to instantly cure specially formulated inks that come into contact with the substrate, like a packaging prototype. While digital printers print all four color combinations of cyan, magenta, yellow, and black (CMYK) in a single press, the UV printing process prints one color at a time.

UV Printing vs. Sublimation Printing

What Is Sublimation Printing?

Also referred to as “dye-sub”, sublimation printing is a form of the digital method of printing commonly used in the textile industry for creativity. It involves dye sublimation produced onto a special transfer paper. The paper is heat-pressed on the fabric, printing the design permanently, and the image will not crack or fade even after the paper is peeled off the printed substrate.

Differences between UV and Sublimation Printing Methods

- Sublimation printing is most common for creating images and text prints on fabrics in the textile industry. Actually, it is restricted to synthetic fabric like acrylic fiber and polyester. On the other hand, UV printing can print on a vast range of surfaces or any material.

- UV printers effectively print on any substrate background with higher image quality. On the other hand, dye sublimation gives adverse results on a darker background.

- Speed has a direct influence on the costs involved in the printing process. In terms of efficiency, UV technology outsmarts sublimation printing since UV printers use a single process, and ink dries instantly. In contrast, sublimation printers use a two-step process and require external heating.

- The infrastructure needed in the two processes also gives a key difference. Dye sublimation requires a printer and a dying heater to complete the process. With UV printing, you only need the UV printer. Therefore, the equipment and maintenance costs will be relatively better with the UV printer.

- Specially formulated UV inks in UV printers have unique properties of eco-friendliness. Also, the inks are firmly cured and dried instantly and cannot produce detrimental compounds. Inks used in the sublimation process are not environmentally friendly, and the sublimation dye produces hazardous waste.

Which Is Better

Based on the differences above, UV printing is better. Although sublimation is essential in the textile industry for producing quality fabric designs, UV printers are more efficient and have eco-friendly inks. UV technology is a revolutionary aspect in the printing industry for customizing and personalizing unique print applications on all surface types.

3 Components of a UV Printing System

1. UV printer

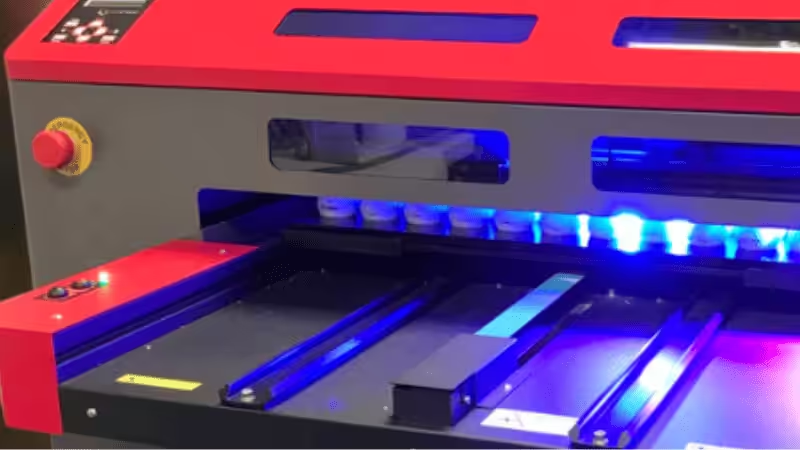

A UV printer, as the name suggests, is a device that uses UV light-curing technology in commercial printing. UV printers come in six models, but we will look at the two main types.

- Flatbed UV printer: Flatbed printers are, as the name suggests, ideal for printing applications on flat surfaces like paper, cards, plaques, and more. Also, you can use a flatbed UV printer model to print cloth or canvas. However, some flatbed UV printers allow the printing of cylindrical objects due to their sizeable surface range.

- Roll-to-roll printers: These UV printers incorporate wide-sized rollers and use advanced technology and adjustable operation levels to produce quality print on a vast array of flexible materials like textile fabric, soft ceiling film, car stickers, wide paper sheets, and canvas items.

Other types of UV printers include rotary UV printers, glass-printing devices, UV digital printers, and direct-to-substrate UV printers.

2. UV inks

Ultraviolet inks are specially formulated and only work with UV printers.

- Characteristics of UV inks

- UV inks are eco-friendly,

- They are specially formulated for instant curing and drying for immediate results

- The inks firmly attach to the substrate

- UV-curable ink is made up of monomers, pigments, oligomers, and photoinitiators

- UV inks are insoluble in water and other organic solvents

- Different types of UV inks: As there is a vast range of UV printing applications, UV curable inks also come in different types to serve all applications and different surfaces. These links are divided into the following main categories:

- Hard or rigid inks – for printing hard materials and surfaces like metal, wood, glass, and ceramic tiles, among other hard items.

- Soft or flexible inks – these UV inks are used for printing soft materials and surfaces such as soft film, soft cloth, wallpaper, car stickers, and more.

- Edible inks – for printing designs on products used for human consumption

- Specialty inks – specialized inks for material with different surface textures.

3. UV Curing System

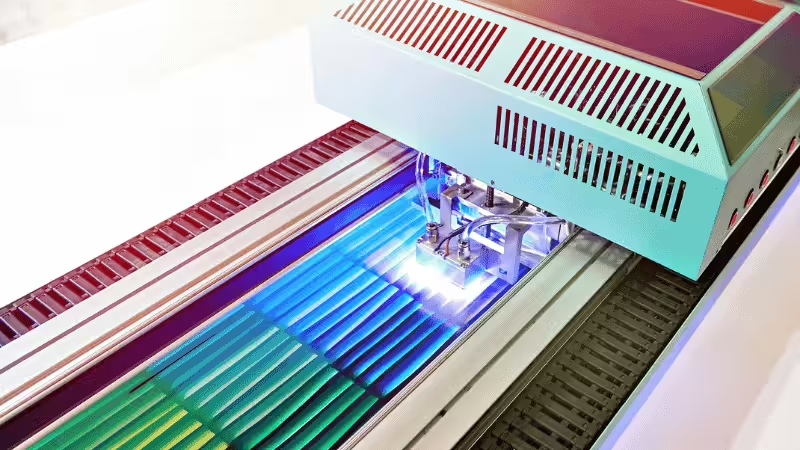

This distinguishing feature sets UV digital printing apart from traditional printing methods. The system is mounted in the print head, and it comprises components that instantly cure ink drops. It produces minimal heat on printing surfaces, making it a comfortable technology for printing heat-sensitive materials.

LED vs. mercury-vapor lamps

LED technology uses curing technology to dry inks efficiently for quality outcomes. The UV Printer has LED laps that follow the ink delivery system, producing UV light that hardens and dries the ink drops. Mercury-vapor lamps generate a lot of heat and energy that is used to cure inks.

However, this method has disadvantages in that these lamps take time to heat up and cool down. So, leaving them on while the printer is on is costly. Also, its heating effect means it is not suitable for heat-sensitive substrates.

Factors affecting the curing process

- The intensity of the UV LED lamps

- UV coating thickness

- Nature and thickness of the substrate

- Working environment temperatures

- Curing speed

How to Choose the Right UV Printer for Your Business

While weighing on having a UV printer in your printing shop, you need to look at some important considerations to obtain the best for your business.

- Assessing your business needs. As stated earlier, UV printers have numerous applications. However, you probably deal with specific printing services. Therefore, assess what your business needs so that the printer does not remain idle after purchase. For example, if your business deals with fabric printing, acquire a printer that will serve cloth printing.

- Comparing different printer models. Different UV printer models are out there, each serving different purposes. Go for a printer model with the best attributes to serve your needs. The models include a flatbed, roll-to-roll printer, Rotary UV printer, Glass-printing device, UV digital printer, and direct-to-substrate UV printer. After comparing their uses, components, printing processes, and overall make, you will probably get the best option from this list.

- Understanding costs and return on investment. This is a crucial consideration if you want to make any investment in your business. After looking at your business needs and the various models in the market, you need to understand the costs that come with such investment. These costs include purchasing, maintenance, and operation costs. As you invest and are ready to incur all these costs, think of the return on investment (ROI) the UV printer will bring to your business.

Advancements in UV LED Technology

1. Integration with Augmented Reality and 3D Printing

The digital world will not stop amazing us. UV LED technology advancements by incorporating augmented reality (AR) and 3D printing in UV digital printing will be revolutionary. Since 3D printers remain unavailable to many, the use of AR can help people access and operate the printer through AR systems.

By doing so, people can design 3D images through the specific AR interface and use UV LED printing technology to produce unique, more interactive surface designs.

2. Sustainability and Eco-Friendly Initiatives

Sustainable printing is good for both society and business. As more people become eco-aware, you need to adopt measures that align with environmental sustainability. Here are some initiatives to achieve sustainability in your business while promoting eco-friendliness:

- Energy saving – UV LED technology does not require a drying heater, thus consuming low energy in the printing process. This can also be achieved by optimizing the number of printers in your office.

- Minimizing toxins – more efficient curing ensures that all ink is used and no ink compounds will evaporate.

- Adopting e-documents over papers

- More use of recycled paper

- Redirecting printing to the most cost-effective printer

- Encourage sustainable printing habits.

Conclusion

As the modern world continues to amaze us with more sustainable solutions, UV digital printing technology is one of the revolutionary solutions in the printing industry. UV printing is more efficient, fast, and cost-effective than many traditional methods. Comparing it with other printing methods is one way to help you know about UV printing.

This printing technology comes with many benefits, and one of them is its eco-friendliness. We have to take initiatives within our printing businesses to ensure the environment remains safe while optimizing service delivery.

Get Quality Prints with a Sustainable Printing Solution

Packoi offers quality package designs and printing solutions to many businesses. They use UV printing technology to print high-quality images and texts on packaging prototypes. For eco-friendly and quality design services, contact us today.