Last Updated on June 23, 2025 by Packoi Team

The global movement to eliminate plastic from packaging is no longer a distant ideal. It’s an urgent imperative. As businesses and consumers alike demand cleaner alternatives, a new wave of biomaterials is stepping up to meet the challenge.

Among them, mushroom packaging stands out not just as an eco-friendly substitute but as a genuine innovation in the way we think about shipping and sustainability. Unlike traditional materials that linger in landfills or oceans for centuries, mushroom packaging biodegrades naturally and nourishes the earth in the process.

It’s a game-changing solution at the intersection of biology, technology, and forward-thinking design. The article below takes a closer look at the benefits and potential of mushroom packaging and how it can shape a greener future.

What Is Mushroom Packaging?

Mushroom packaging is a sustainable packaging material made from mycelium, the root structure of mushrooms. When combined with agricultural waste like hemp or corn husks, mycelium grows into molds that form strong, lightweight shapes.

This natural process takes less than a week and requires minimal energy, making it one of the most eco-efficient packaging solutions available today. The final product is firm, yet slightly spongy, similar in feel to Styrofoam.

Its surface is off-white or beige, with an organic texture. Despite its natural look, it holds up well under pressure. It’s fire-resistant, water-resistant to a degree, and fully compostable at home or in soil. That makes it an attractive alternative to plastic packaging, which can take hundreds of years to decompose.

Structurally, mushroom packaging performs exceptionally in protecting fragile goods. It can be molded into custom shapes, making it ideal for custom packaging needs like electronics, cosmetics, and glassware. It’s shock-absorbent and durable in transit, just like expanded polystyrene foam.

Where it differs is in impact. Traditional plastic packaging pollutes waterways, generates CO₂ during production, and adds to landfills. Mushroom packaging, in contrast, returns to nature within 30–60 days after disposal.

How Is Mycelium Packaging Made?

Mycelium packaging is created through a clean, low-energy process that combines agricultural waste with fungal biology. Here’s a step-by-step breakdown:

- Collect Agricultural Waste

Materials like corn husks, hemp hurds, or sawdust are gathered. This waste acts as the nutrient base. - Sterilize and Inoculate

The agricultural waste is cleaned and sterilized. Mycelium (fungi roots) is then added. - Grow the Mycelium

The mixture is placed into molds. Over 4–6 days, mycelium grows, binding the waste into a solid form. - Mold Customization

Custom molds allow precise shaping for product fit. This enables custom packaging tailored to different industries. - Curing and Drying

Once fully grown, the formed material is heat-treated. This halts fungal growth and hardens the shape. - Final Product

The result is a dry, durable, and biodegradable packaging material ready for use.

This entire cycle, from inoculation to cured packaging, typically takes 7 to 10 days, depending on temperature and mold size. Unlike petroleum-based plastic packaging, this process requires no synthetic chemicals or toxic emissions.

In terms of scalability, mycelium packaging is already in commercial use. Modular growing systems make it viable for small startups and large enterprises alike. As demand for sustainable packaging grows, so does the infrastructure for high-volume production.

The ability to mold the material into precise, protective shapes positions mycelium as a serious contender in the packaging solutions market, especially for brands seeking low-impact, regenerative alternatives to foam and plastic.

Environmental Benefits of Mushroom Packaging

Mycelium packaging offers a clear environmental advantage over conventional materials. It is a form of biodegradable packaging that breaks down naturally in soil within 30 to 60 days. No industrial composting or chemical treatment is needed.

Once disposed of, it decomposes into organic matter, enriching the soil without leaving behind toxins or microplastics. Unlike petroleum-based plastics, which persist for centuries, mycelium packaging is made from agricultural and food waste.

This process diverts waste from landfills and repurposes it into something useful. The entire growing cycle requires little water and no synthetic additives. Energy consumption is minimal, especially compared to plastic and foam production, which depend heavily on fossil fuels.

Another key benefit is ocean safety. Mycelium packaging poses no risk to marine life. If it ends up in waterways, it simply biodegrades. In contrast, plastic pollution is now a global crisis, harming ecosystems and entering the food chain.

When it comes to emissions, mycelium packaging contributes to lowering the carbon footprint of shipping and manufacturing. Some researchers even refer to it as a carbon-negative solution, because the growing process can capture more carbon than it emits.

The Sustainable Packaging Coalition and other environmental groups are increasingly recognizing such materials for their potential to reshape the industry. Whether used in the food industry, electronics, or consumer goods, mycelium packaging offers a credible, scalable alternative to traditional foams.

Key Use Cases and Applications

Mushroom packaging has found its use cases in a wide range of industries. Some of them are as follows.

Electronics and Fragile Item Protection

Mycelium packaging is gaining traction in the electronics industry. It works well as a shock-absorbent cushion for phones, laptops, and glass components. It performs like foam but breaks down naturally, so it’s ideal for companies seeking sustainable alternatives to traditional plastic.

Cosmetics and Small Goods

For cosmetics and personal care products, mycelium packaging offers precise molding. It fits snugly around delicate jars and tubes, reducing movement and preventing breakage. It also boosts brand appeal for businesses focused on eco-conscious values.

Food Service and Takeaway Packaging

In the food sector, mycelium packaging competes with cornstarch packaging and other compostable materials. It’s ideal for takeout containers, trays, and insulation liners. Made from agricultural waste, it’s food-safe and supports a healthier environment.

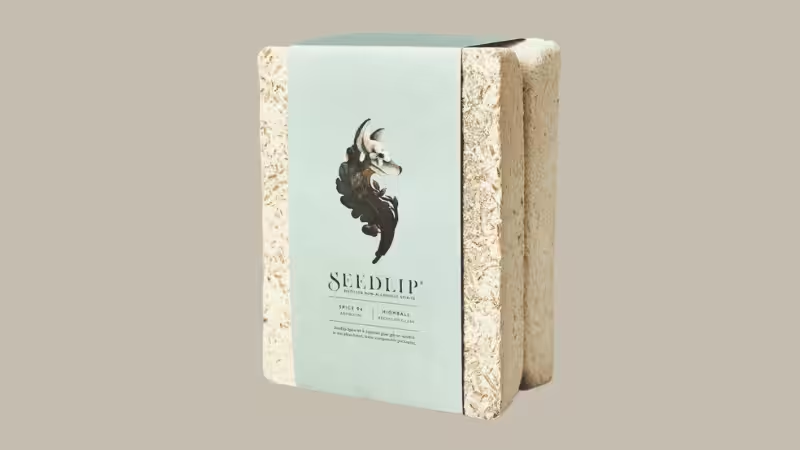

Artisanal Brands and E-Commerce

Sustainability-focused e-commerce and artisanal brands are early adopters. These businesses use mycelium packaging to align with eco-values and reduce waste. Its clean look and compostability reinforce a commitment to the circular economy.

Mushroom Packaging vs Other Biodegradable Alternatives

Mushroom packaging offers distinct advantages over other biodegradable options like cornstarch packaging, paper, and molded fiber. While all of these are better than traditional plastic, mushroom packaging is grown from agricultural waste, making it a carbon-negative solution. It’s also more durable than paper and less water-intensive than molded fiber.

| Feature | Mushroom Packaging | Cornstarch Packaging | Paper Packaging | Molded Fiber |

|---|---|---|---|---|

| Source Material | Agricultural waste + mycelium | Corn/plant starch | Wood pulp | Recycled paper pulp |

| Biodegradability | Fully home compostable | Compostable (may need facilities) | Biodegradable | Biodegradable |

| Strength & Protection | High (shock absorbent) | Moderate | Low | Moderate |

| Water Resistance | Moderate | Low | Low | Moderate |

| Energy to Produce | Low | Moderate | Moderate | High (water & heat needed) |

| Custom Moldability | Excellent | Good | Poor | Good |

| Ideal Use Cases | Fragile goods, electronics, food trays | Food containers | Bags, wrapping | Trays, inserts |

| Compost Time | 30–60 days | 90+ days (varies) | 60–90 days | 90+ days |

| Carbon Footprint | Very low (carbon negative solution) | Moderate | Moderate | High |

Mushroom packaging is becoming more cost-competitive as production scales. While it may currently cost slightly more than traditional plastic or paper packaging, it offers better durability and protection, especially for fragile items.

Compared to cornstarch packaging and molded fiber, it performs better in cushioning and custom moldability. Its use of agricultural waste as a feedstock helps reduce raw material costs and contributes to a circular economy.

Mycelium packaging is dry, stable, and inert once cured. It can be stored in warehouses or shipping facilities for months without degradation, as long as it stays dry.

Unlike some biodegradable packaging types that may warp or weaken in humid environments, cured mycelium packaging holds its form. However, prolonged exposure to moisture could soften the material, so indoor storage is ideal.

It’s not intended for long-term reuse like plastic, but it holds up well during typical shipping and handling cycles. Brands using it for product packaging in e-commerce, food service, or fragile goods find it reliable, protective, and easy to store.

Brands Using Mushroom Packaging Today

Several major brands have integrated mycelium packaging into their operations as part of broader sustainability commitments.

- IKEA: One of the earliest adopters, IKEA uses mushroom-based packaging to protect fragile items during shipping. The company has committed to eliminating traditional plastic in all packaging by 2028 and sees mycelium packaging as a key component of that transition.

- Dell Technologies: Dell uses mycelium packaging to ship lightweight servers and electronic components. The material’s shock-absorbing quality allows for safe transit while reducing waste. Dell reported lower packaging-related emissions after switching.

- Ecovative: While not a brand using it for shipping their own goods, Ecovative supplies the raw material and tech that powers most mushroom packaging systems today.

The sustainability initiatives of these brands show how sustainable packaging could scale without sacrificing performance.

Small Businesses That Have Made the Switch

Many small and mid-sized brands are embracing sustainable alternatives to align with eco-conscious consumers:

- Loliware: A sustainable product company using compostable materials like seaweed and exploring mycelium packaging for future expansions.

- Pym: A wellness brand using mycelium-based packaging for supplement shipments to reduce plastic use and appeal to eco-focused buyers.

- Custom candle and soap makers: Many artisans on platforms like Etsy now use mushroom packaging for its aesthetic, minimalism, and biodegradability, helping them build a healthier environment ethos into their unboxing experience.

These examples show that mushroom packaging is both scalable for enterprises and accessible for small businesses committed to greener practices.

Is Mushroom Packaging the Future of Sustainable Shipping?

Mushroom packaging is gaining traction as a long-term solution to the global packaging crisis. As the demand for sustainable materials grows, so does investment in mycelium technology. Companies are no longer treating it as a niche option; it’s entering the mainstream.

Market Trends and Investment

Startups like Ecovative and MycoWorks have attracted millions in funding. Their focus is scaling mycelium packaging for global use. Big brands are taking notice. There is clear momentum from:

- Corporate sustainability targets

- Global bans on petroleum-based plastics

- Consumer pressure for greener packaging solutions

More investors are seeing fungi-based materials as a competitive market. The value is in both environmental impact and long-term cost reduction.

Innovations in Biofabrication

New biofabrication methods make mycelium packaging faster and stronger. Labs are experimenting with:

- Stronger fungal strains

- Faster curing methods

- Hybrid blends with agricultural waste

These innovations reduce production time and improve durability. It’s making the material suitable for more than just custom packaging; it’s becoming viable for bulk use.

Beyond Packaging: A Versatile Future

Mycelium is not limited to shipping applications. Its structure is naturally insulating, breathable, and durable. This opens doors in:

- Building insulation

- Acoustic panels

- Leather-like textiles

- Furniture cores

Researchers are testing it as an eco-friendly alternative to foam boards and even fashion materials. The potential is wide. With continued investment, mycelium packaging could transform more than just shipping. It could reshape how we build, ship, and wear products in a circular economy.

FAQs

Is mushroom packaging safe for food contact?

Yes, mushroom packaging is generally safe for food contact, especially when grown and processed under controlled, clean conditions. It’s made from agricultural waste and mycelium, without toxic chemicals or glues. Many producers ensure it meets food safety standards for packaging dry goods or takeaway containers.

How long does mushroom packaging take to break down?

Mushroom packaging typically breaks down in 30 to 60 days under home composting conditions. Its composition makes it highly biodegradable. When exposed to moisture, microbes, and oxygen, it naturally decomposes into nutrient-rich compost, leaving behind no toxic residue or microplastics in the soil.

Can I compost mushroom packaging at home?

Yes, you can compost mushroom packaging at home. It’s fully biodegradable and made from natural compostable materials like fungi roots and plant fibers. Just break it into smaller pieces and add it to your compost bin or pile. It will break down within a few weeks to two months, depending on temperature and moisture levels.

Conclusion

Mushroom packaging is a transformative shift in how we think about packaging. With continued investment, innovation, and consumer awareness, it has the potential to become a new industry standard. For brands committed to reducing waste and supporting a healthier environment, mycelium packaging offers real, scalable impact. Now is the time to explore this powerful solution.

Jump on the Mycelium Packaging Bandwagon With Packoi

Looking to swap out your plastic or foam packaging for something greener? Explore mushroom packaging options from Packoi. Get in touch with us to learn about your sustainable packaging options.