Last Updated on March 21, 2025 by Packoi Team

More brands are choosing digital printing for packaging because it’s cost-effective and allows for quick changes. Whether you’re a small business or a large company, this technology offers big advantages.

It reduces waste, speeds up production, and delivers eye-catching packaging. Want to know more? Let’s explore how digital printing is used in packaging and why it’s becoming the go-to choice for brands.

What Is Digital Printing?

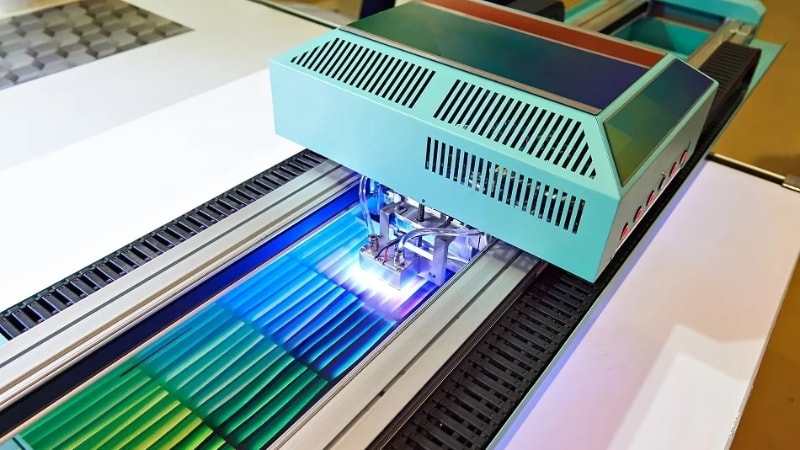

Digital printing is a modern printing method that transfers digital images directly onto different materials. It prints from a digital file, like a PDF, straight to the printer. The process allows for custom digital printing, making it easy to personalize packaging with unique designs, colors, and branding.

This process works by mapping an image onto a surface using tiny droplets of ink. The result is sharp, vibrant prints with great detail.

Many industries now use digital printing technology in packaging because of its speed and efficiency. It’s especially useful for businesses needing quick turnarounds and multiple design variations.

While digital printing vs offset printing depends on volume and cost, digital is ideal for flexible, short-run packaging. Overall, this method is reshaping how brands approach packaging design and production.

How Does Digital Printing Work?

Digital printing starts with a digital file, like a PDF. This file is sent directly to a digital printer, eliminating the need for printing plates. The printer then applies ink or toner onto the chosen material.

There are two main types: inkjet and laser printing. Inkjet printers spray tiny droplets of ink onto the surface. In contrast, laser printers use heat to fuse toner powder. Both methods ensure precision and vibrant colors, making them ideal for digital printing for packaging.

Color management plays a key role. Digital printers use CMYK (cyan, magenta, yellow, and black) to produce accurate shades. Advanced software ensures consistency across different prints. The process works on various digital printing packaging materials, from paper and cardboard to flexible films.

Digital Printing Technologies Used in Packaging

The following technologies are used in digital printing for packaging.

Inkjet vs. Laser Printing

Inkjet printers spray tiny droplets of ink onto a surface. So, they are ideal for high-resolution images and vibrant colors. They work well on flexible packaging and labels.

Laser printers use heat to bond toner to the printing material. They offer fast printing speeds and sharp text, making them great for barcodes and high-volume jobs. When comparing digital printing vs offset printing, inkjet is better for customization, while laser excels in efficiency for simple designs.

| Feature | Inkjet Printing | Laser Printing |

|---|---|---|

| Printing Technology | Uses liquid ink sprayed onto the surface | Uses toner powder fused onto the surface with heat |

| Print Quality | Produces vibrant colors and high detail | Offers sharp text and precise lines, better for monochrome prints |

| Speed & Efficiency | Slower but suitable for detailed, color-rich prints | Faster, making it ideal for bulk printing |

| Material Compatibility | Works well on various surfaces, including flexible packaging | Limited to certain coated and uncoated materials |

| Best Use Cases | Ideal for custom digital printing, labels, and packaging with complex designs | Best for high-volume printing and digital printing packaging that requires sharp text |

UV Digital Printing

UV digital printing uses ultraviolet light to cure ink instantly, creating sharp, durable prints. This technology works on various surfaces, including plastic, glass, and metal.

It’s a great choice for custom digital printing since it produces scratch-resistant, vibrant images with a premium finish.

HP Indigo & Other Advanced Digital Presses

HP Indigo presses stand out for premium digital printing packaging. They use liquid electrophotography (LEP) to deliver offset-quality prints with the flexibility of digital.

Other high-end presses offer advanced color accuracy, making them perfect for luxury packaging and brands that need top-tier results.

How Digital Printing Is Used in Packaging?

Digital printing has transformed the packaging industry in many ways, including the following.

Food & Beverage Packaging

In the food and beverage industry, digital printing for food packaging is a game-changer. It allows brands to create custom digital printing designs for labels, cartons, and flexible pouches.

Since there’s no need for printing plates, companies can easily update the packaging for seasonal promotions, limited editions, or regulatory changes.

One major advantage is color consistency. Digital printing uses CMYK and advanced color management to ensure vibrant, accurate branding.

It’s also great for small batches, helping craft breweries, specialty food brands, and organic product makers create unique, professional packaging without high costs.

E-Commerce Packaging

With the rise of online shopping, e-commerce brands are using digital printing packaging to enhance the customer experience. Personalized packaging, limited-edition prints, and high-quality branding make unboxing exciting. Companies can print unique messages, QR codes, or interactive designs directly on boxes, mailers, and inserts.

Since digital printing enables fast turnarounds, businesses can respond to trends quickly. For example, they can create packaging for special sales, holidays, or influencer collaborations without high setup costs.

Luxury Packaging

Luxury brands demand high-quality digital printing for their packaging to reflect exclusivity and sophistication. HP Indigo and other advanced digital presses offer exceptional print clarity, color depth, and premium finishes.

Techniques like metallic inks, embossing, and spot UV coatings elevate packaging for perfumes, cosmetics, and designer goods. Unlike digital printing vs offset printing, digital methods allow for cost-effective short runs, perfect for high-end limited editions.

The ability to personalize each piece also makes digital printing ideal for premium gifting and VIP customer experiences.

Sustainable Packaging

Sustainability is a growing priority, and digital printing technology in packaging is helping brands reduce their environmental impact. Unlike traditional printing, digital methods produce less waste, use fewer chemicals, and require minimal setup materials.

Custom digital printing supports eco-friendly packaging by allowing brands to print on recycled and biodegradable materials without compromising quality. Water-based and UV-curable inks reduce pollution, making packaging safer for both consumers and the planet.

Another key benefit is the reduction of overproduction. Since businesses can print on demand, they avoid excess inventory and waste. It makes digital printing vs traditional printing a greener choice, helping brands align with sustainable values while maintaining high-quality packaging.

Digital Printing vs. Other Printing Methods

Digital printing is the best choice for short runs. It requires no setup time since there are no printing plates, making it much faster for small-batch production.

Offset printing, while efficient for high volumes, takes longer to prepare. Digital printing for packaging lets businesses print what they need. It helps reduce waste and storage costs.

Offset printing has high upfront costs due to plate creation and setup. However, it becomes cost-effective for large-scale production. Custom digital printing eliminates setup fees, which is best for businesses that need flexibility.

Digital printing technology in packaging has advanced significantly, offering sharp details and vibrant colors. While offset printing provides slightly better color consistency for very large runs, digital printing uses CMYK with precise color management.

One of the biggest perks of digital printing packaging is design customization. Brands can personalize labels, add unique QR codes, or create region-specific versions without extra costs.

Variable data printing (VDP) allows for individualized prints in a single run, making digital the best choice for personalized marketing, promotions, and limited-edition packaging.

Benefits of Digital Printing in Packaging

Digital printing for packaging offers speed and efficiency since it doesn’t require printing plates. Brands can easily update designs, making custom digital printing ideal for limited-edition and seasonal packaging.

It’s also an eco-friendly choice, reducing waste and energy consumption compared to traditional methods. Plus, digital printing works well with sustainable materials.

For small and medium print runs, it’s highly cost-effective, eliminating expensive setup fees. Businesses can print what they need, reducing excess inventory and costs while ensuring high-quality, eye-catching packaging.

Limitations and Challenges of Digital Printing

While digital printing for packaging is flexible, it has some drawbacks. The cost per page is higher than traditional offset printing, making it less economical for very large print runs.

Some commercial digital printing processes may lose fine-image details, affecting intricate designs. Additionally, digital printing is limited to specific materials and may not be ideal for large-format packaging.

Color accuracy can also be a challenge. While CMYK technology provides good results, it may not match the precision of offset printing, especially for brands requiring exact color consistency across large production batches.

Future of Digital Printing

The digital printing press is evolving rapidly, with advancements in technology closing the quality gap between digital and traditional methods. Improved color accuracy, faster printing speeds, and better material compatibility are making digital printing for packaging even more competitive.

As demand for custom digital printing grows, businesses are embracing its cost-effectiveness and flexibility for short runs and personalized designs. Sustainability efforts are also driving innovation in professional printing with eco-friendly inks and reduced waste solutions.

Conclusion

Digital printing for packaging offers a fast, flexible, and cost-effective solution for modern businesses. It eliminates the need for printing plates, allowing for custom digital printing and quick design changes.

With high-quality output, personalization options, and eco-friendly benefits, digital printing is shaping the future of packaging and branding.

Opt for Digital Printing for Futuristic Packaging

Planning to use digital printing for packaging? At Packoi, we offer comprehensive design solutions to businesses for branding and production. Get in touch today.