Last Updated on August 28, 2023 by Packoi Team

By recycling paper and plastic film, we can reduce the need for new raw materials, save energy, water, and chemicals, and minimize the pollution caused during production.

Any organization and individual—businesses, families, and schools—can contribute to environmental projects that save resources, reduce waste, and create more sustainable communities. Change your paper to something better for the planet today!

Types of Paper Recycling

An important part of the production of recycled paper is paper recycling, which helps to reduce waste and maximize resource efficiency. This is a sustainable approach that ensures the reuse of fiber and wood materials. There are two main types of paper recycling: pre-consumer paper recycling fiber recycling and post-consumer paper production fiber recycling.

Pre-Consumer Recycling

Pre-consumer recycling involves reusing waste paper scraps and trimmings from the manufacturing processes of paper materials. This type of recycling occurs before the paper products reach the consumer. It focuses on utilizing leftover materials during the paper recycling production stage, reducing waste right at the source of the paper-making machine. Pre-consumer recycling helps make paper production more sustainable by repurposing these manufacturing byproducts instead of discarding them.

Post-Consumer Recycling

Post-consumer recycling, on the other hand, focuses on collecting used paper products from consumers for processing into new paper. This type of recycling aims to extend the lifespan of paper by giving it a second chance at usefulness. Collected papers go through various steps, such as sorting, cleaning, and pulping, to remove contaminants from the pulp and transform it into pulp suitable for producing recycled paper.

Both paper manufacturers and pre-and post-consumer recycling contribute significantly to increasing the overall paper recycling rate and reducing environmental impact. By diverting waste from landfills and conserving valuable resources like trees and water, these paper mills and recycling methods play a crucial role in creating a more sustainable future for paper materials.

Recycling of Waste Paper: Recyclable and Non-Recyclable

Recycling waste paper involves converting used or discarded paper products into new paper or other products. Recycling paper can help conserve resources, reduce energy consumption, and minimize waste.

Recyclable paper products include handmade paper only:

- Paper and cardboard containers, such as cardboard boxes, soda cans, and milk cartons.

- Office paper, such as printer paper, copier paper, and envelopes.

- Newspapers and magazines, including those with glossy or colored coatings.

- Old books, including hardcover and paperback books.

- Mailing envelopes.

- Paperboard packaging, including egg cartons, pizza boxes, and cake and muffin wrappers.

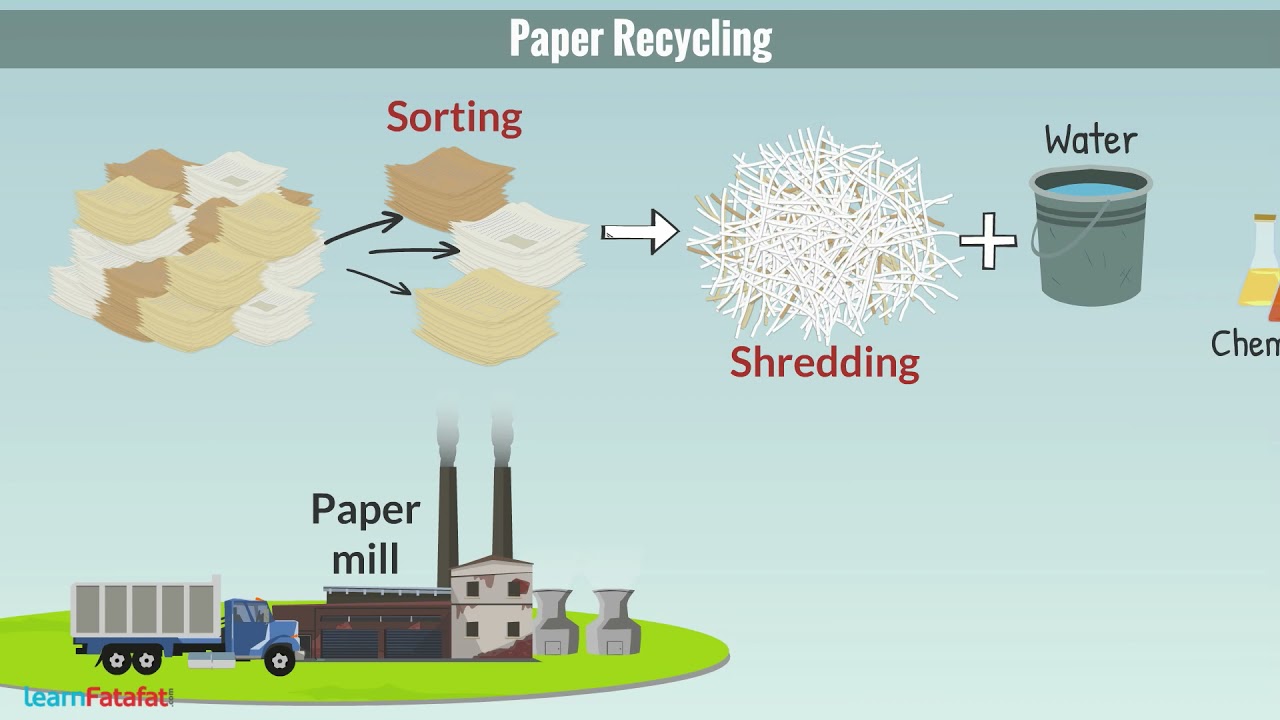

The above list of paper products can be recycled through a process called paper recycling, which involves sorting, collecting paper mill parts, pulping, de-inking, bleaching, sheet formation, printing, finishing, testing, and distribution.

Non-recyclable paper products include colored paper only:

- Paper towels and tissue paper, as these products are not designed to be recycled.

- Paper with food stains or oil, as these products can contaminate the recycling process.

- Paper with large amounts of plastic or metal, such as envelopes with plastic windows, can be difficult to separate from paper.

- Photographs and printed photos, as these products contain dye and chemicals that can be harmful to the environment.

- Newsprint, as it contains large amounts of ink and dyes that can contaminate the recycling process.

- Paper with large amounts of glue, such as paper bags and envelopes with glue seals, as these products can be difficult to separate from the paper.

It is important to check with your local recycling center or waste management company to determine what types of paper products can be recycled in your area. By recycling paper, we can help reduce waste, conserve resources, and create more sustainable communities.

The Step-by-Step Production Process of Recycled Paper

The paper recycling process involves several stages, each carefully designed to remove impurities from wet paper and transform collected paper into reusable pulp. Let’s take a closer look at how recycled paper pulp is produced:

- Sorting and collection: This is the first step in the production process, where the waste paper is sorted and collected from various sources such as offices, homes, and businesses.

- Pulping: The sorted paper is then processed to remove any impurities or contaminants, such as plastics, metals, and glass. This is done through a process called pulping, which involves grinding the paper into a pulp.

- De-inking: The pulp is then processed to remove any ink from the paper. This is done through a process called de-inking, which involves using chemicals to dissolve the ink into the pulp.

- Bleaching: The pulp is then processed to remove any remaining impurities, such as colorants or contaminants. This is done through a process called bleaching, which involves using chemicals to lighten the pulp.

- Sheet formation: The bleached pulp is then formed into a sheet of paper through a process called sheet formation, which involves pressing the pulp through screens to remove excess water and form a sheet of paper.

- Printing: The sheet of paper can then be printed using a printing press.

- Finishing: The printed paper can then be finished with a coating or other treatments to improve its quality and durability.

- Testing: The finished paper can then be tested to ensure it meets the required standards for strength, finish, and color.

- Distribution: The finished paper can then be distributed to customers, either as a recycled paper product or as a raw material for further processing into other products.

Advanced technologies are employed throughout these stages to maintain quality standards for producing new paper items. By understanding this intricate industrial process, we gain an appreciation for the effort required to make recycled paper production possible.

Recycling recycled paper not only helps reduce deforestation, but the entire process also conserves energy and reduces landfill waste. So next time you use recycled paper products, remember that they have gone through this extensive process to give them a second life while protecting our environment.

Reducing Pollution through Recycled Paper Production

Producing recycled paper has numerous environmental benefits and plays a crucial role in reducing pollution. Here’s how recycled paper production helps protect our planet:

- Significantly lower energy consumption: Making paper from recycled fibers requires much less energy compared to producing new paper products from virgin materials. This reduction in energy consumption translates into fewer greenhouse gas emissions and contributes to mitigating air pollution.

- Preserving natural habitats: By using waste paper instead of cutting down trees, the production of recycled paper helps reduce deforestation. This preservation of forests is essential for protecting biodiversity and preserving natural habitats for countless species.

- Minimizing water pollution: The deinking process involved in recycling paper plays a vital role in minimizing water pollution. Harmful chemicals present in the pulp are removed during this process, preventing them from contaminating water sources and ecosystems.

- Reducing greenhouse gas emissions: Opting for recycled paper over conventional options contributes to lowering greenhouse gas emissions associated with the paper industry. These emissions are a significant contributor to climate change, making the use of recycled fibers an effective way to combat global warming.

By considering these factors, it becomes clear that recycling paper is an important step towards environmental protection and pollution reduction. Through reduced energy consumption, the preservation of natural habitats, minimized water pollution, and decreased greenhouse gas emissions, we can make a positive impact on our planet’s health.

So why not choose recycled paper? Together, we can make a difference by supporting sustainable practices that benefit both our environment and future generations.

Challenges Faced by the Recycling Industry

Recycling paper and scrap paper is essential for reducing waste and preserving natural resources. However, the recycling scrap paper industry faces several challenges that hinder the production of recycled paper.

Contamination of Recyclable Paper

Contamination is a major issue in the recycling industry. Recyclable paper often gets mixed with non-recyclable materials like plastic, food waste, or hazardous substances. This contamination makes it difficult to separate and process the recovered paper more effectively.

Lack of Awareness Among Consumers

Many consumers are not aware of proper recycling practices. As a result, they unknowingly include non-recyclable items in their paper waste, leading to lower-quality feedstock for recycled paper production. Educating consumers about what can and cannot be their own recycled paper is crucial to improving the quality of recyclable materials.

Fluctuating Market Demand and Pricing

The demand for recycled paper varies over time, causing fluctuations in market prices. Recycling facilities rely on stable market conditions to ensure economic viability. When prices for shredded paper drop too low due to reduced demand, it becomes financially challenging for these facilities to continue operating efficiently.

Handling Complex Packaging Materials

Complex packaging materials pose a significant challenge for the recycling industry. Items such as multi-layered plastics or composite packaging are harder to process compared to simple paper products. Developing efficient technologies capable of handling these complex materials is necessary to enhance recycling capabilities.

Conclusion

Now that you have a better understanding of how recycled paper is produced, it’s clear that making paper recyclable is crucial for our environment. Recycling paper not only helps preserve our forests but also contributes to a more sustainable future.

So what can your business do? Use environmentally friendly recycled paper, design environmentally friendly recycled paper packaging, and promote the green concept of the enterprise. By promoting green ideas, encourage others to do the same. Together, we can have a significant impact on reducing waste and protecting the planet.

Discover the Perfect Package Solution for Your Business with Packoi Printing

We are passionate about packaging and proud to be the packaging partner of choice for our customers.

Packoi Printing is an FSC-certified packaging company that works with you to create an environmentally friendly packaging solution that will make your product stand out in a crowded market.

Contact us today, and we will have the perfect package solution for your business.