Last Updated on December 26, 2022 by Packoi Team

There are hundreds of designs you can use for your custom rigid boxes. Before we go any further, let us dive into the details as we explain to you what rigid boxes are.

What are Rigid Boxes and What are They Used For?

Rigid boxes are sturdy paper boxes with high-thickness chipboard wrapped in decorative papers. Rigid boxes are hard and with maximum protection design for shipping fragile and highly expensive items such as phones. Rigid boxes help deliver gifts to customers as they have an amazing appearance. In addition, manufacturers use rigid boxes to improve a brand’s value, for instance, Apple products.

The Different Types of Rigid Boxes

There are two main types of rigid boxes available. We will explain in detail these two major types below.

Partial Finish Rigid Boxes

The wrapping paper in partial finish rigid boxes covers only the outside surface of the box, and the chipboard inside is visible. Just as the name suggests, partial cover rigid boxes shield some parts of the boxes. These rigid boxes are easy to make using single chipboard pieces and utilize few materials. The materials are biodegradable and cause minimal waste.

Full Finish Rigid Boxes

Full finish rigid boxes are completely covered, and the chipboard is not exposed. The chipboards are laminated as per the customer’s need and are extra thick paperboard. Full rigid boxes offer additional wrapping either in normal white or printing. These rigid boxes serve best when someone is wrapping a gift or a custom-made item.

Rigid Boxes Style

There are several types of rigid box styles. The style chosen by a particular business depends on the products being shipped, the size of the products, branding elements, and the shipping model adopted. Here are some of the popular rigid box styles available in the market.

Tube Packaging

A unique way of rigid box packaging that’s of telescope rigid box styles opening. The rigid packaging utilizes eco-friendly paper style for brands. This rigid box packaging’s tend to be more innovative and sustainable due to their eco-friendly nature. Furthermore, these packaging are affordable.

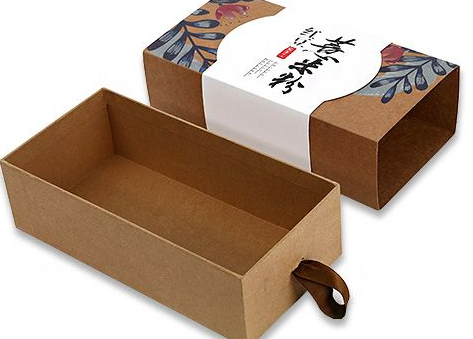

Drawer Style Rigid Boxes

Drawer style boxes are also known as slide or match and unbox as matchboxes. Drawer rigid box packaging opens by pulling an attached ribbon, and accidents are minimal as the design ensures easy opening. Furthermore, drawer style boxes are children-friendly by integrating children’s features to ensure no harm.

Magnetic Closure

Rigid box packaging with two magnets closing the box with a snap sound. Magnetic closure boxes use premium and luxury packaging styles that mostly store expensive products such as jewelry. Magnetic closure boxes are durable and give the one who is receiving the package a unique feeling when unboxing. Besides, magnetic closures are collapsible rigid boxes with double-sided tape necessary to hold the box tightly. They offer maximum protection as compared to another packaging.

Book Style Rigid Boxes

An innovative rigid box that opens like a book cover. The book-style rigid box is opened through seals by either a button strap mechanism or two magnets, creating a distinctive value. Book style rigid boxes provide brand identity, which enhances the company image.

Shoulder Neck Rigid Boxes

A packaging that provides custom rigid boxes to the clients. Shoulder neck rigid boxes has layers that give the packaging a unique touch, especially for pricey gifts. The premium packaging allows for unique customization through folding cartons in multiple layers and is best for items with less weight.

Telescopic Boxes

Telescopic rigid box that utilizes traditional packaging models and is firm. They cover the base of the product and ensure exact measurements of the product in the box to allow for slow opening speed. Moreover, it offers maximum protection and is a robust packaging option as it is sturdier than the other rigid box alternatives.

How to Choose the Right Rigid Box for Your Product

The quality of your rigid packaging reflects on your company. Therefore, it is crucial to make the right decisions when deciding on the right manufacturer. When making the decisions, the factors below should guide you toward selecting the best manufacturer. They include:

Capabilities

When selecting the manufacturer, it is important to analyze their ability to produce the right quantity and quality packaging. Read other clients’ reviews on google and social media platforms and remember to always ask for samples of their work. The samples act as a guide and evidence that they can meet your designing rigid packaging desires.

Price

It is good to always ask for quotes from different manufacturers to help in comparing the prices. Select a manufacturer who can meet your budget and provide high quality packaging types. Do not settle on cheap manufacturers who cannot meet your needs but consider the affordability and quality of their work.

Location

Always consider the regions with most of your customers. Choosing a manufacturer near your customers saves on shipping and handling costs. In addition, it saves transit time with no or fewer damages.

Certifications and Licenses

Consider a manufacturer that meets all the company requirements and needs, such as government regulations, if any, or approvals.

After outlining the factors to consider when choosing a packaging manufacturer, let us discuss tips for choosing the right rigid box for your product.

Materials

Identify the product needs in the market and how you always meet them. Consider rigid boxes with good qualities and are environmentally friendly to avoid pollution. In addition, consider what materials give your brand identity and allow for customization, such as branded rigid gift boxes.

Budget

The amount allocated towards rigid packaging affects the decisions such as shipping volume, rigid packaging style, materials, and designs such as those with magnetic closures. Consider all costs to be involved and select the most rigid box styles. Rigid box styles create a unique value, and customers enjoy the premium packaging option. Besides, always plan as per your budget and remember that custom rigid boxes are good but expensive.

Packaging Size

Packaging types can limit the choice of your rigid boxes. What the product is and how fragile it is another important aspect. The size can limit rigid boxes such as telescopic versus tube packaging inserts. To make the right choice, always understand your product and its roles in the market, whether it is a new one, a well-established one, or future product goals.

Weight

The weight of your product influences the selection of rigid boxes. For bulky products, you select materials with strong inner chipboards and rigid boxes with multiple layers for luxury products. Furthermore, consider flexible packaging.

Value

Select a rigid box that matches the product value. For example, smartphone boxes are different from watches boxes. The value should match the product quality and multi packaging impression.

Benefits of Rigid Boxes

There are several benefits you get for using rigid boxes as your packaging option. While the advantages differ depending on the nature of the business, location, and price, among other factors, the ones outlined below are the most common benefits.

Protection

Rigid boxes enhances product protection during their shipment. Quality rigid boxes protect the products against scratches and harsh handling. In addition, it offers a luxurious look to your product, unlike other packaging.

Gift-Type Packaging Boxes

Customers who receive custom rigid boxes enjoy the product and company identity. They always want to associate with such, and the company builds positive public impressions.

Reusable

Rigid box packaging materials are reusable as a way of saving the planet. Customers who receive products in such packaging tend to reuse them, thus creating eco-friendly environments.

Brand Identity

Rigid packaging creates a unique value when the company invests in the right boxes. Shipping is unique rigid packaging that draws attention, growing the customer base and increasing the company’s sales.

Flexible Packaging

Different rigid box types offer various options for packaging the products. Flexible packaging increases convenience and gives products an undefinable look.

Tips on Packaging Your Product in a Rigid Box

Identify the type of rigid boxes; understand the rigid setup boxes to ensure the packaging fits, such as jewellery versus shoes. Consider the rigid box materials, for instance, grey chipboard material versus colored chipboard fits different products.

Understand the style of your rigid boxes before packaging your products. Also, the value of the product can assist in packaging. For instance, rolled edge tube packaging versus match rigid boxes; shoes versus board games luxury products.

Conclusion

Rigid boxes offer a superior feel and support associated with your products. Every business needs to understand the role of rigid boxes and how they help create brand awareness. The benefits of rigid boxes range from sustainability to luxury promotions and protection against damage. The custom rigid boxes continue to appreciate the need for gifts and add value to the human experience. It is important to understand the rigid box types, the packaging, and how to get the right quality of your product. Even though price plays a crucial role in determining rigid paperboard boxes, other factors include manufacturer, product value, customer satisfaction, and the need for quality packaging. Packaging is a silent agent in the market but proves to be a worthwhile investment as per return on investment. The packaging types create awareness, satisfy customers, and enhance the company’s reputation.

At Packoi Printing, we aim to provide businesses with affordable packaging alternatives. Our high quality custom rigid boxes increase the customer’s experience and credibility. We take pride in your growth; thus, with every order, we personalize it well and ensure it meets your business needs. Besides, we offer a variety of packaging as various businesses focus on different markets. We are all-inclusive, and our products are eco-friendly. Contact us for all your custom rigid packaging.