Last Updated on March 4, 2025 by Packoi Team

Sublimation printing is a digital printing method applied extensively across the market. With this technique, the design is transferred from a sublimation paper to a substrate or fabric.

When you are making dye sublimation, it is possible to utilize a sublimation-specific printer that offers professional outcomes. Some of the known printers for this purpose include inkjet printers that make converting to sublimation easy. The printers usually utilize sublimation ink cartridges with specialized dye particles in a liquid.

Through sublimation, a solid substance is converted to a gaseous state without becoming a liquid. Therefore, sublimation ink is formulated in a way that allows it to change from a solid to a gaseous state. It is worth noting that these ink types come with several advantages and disadvantages.

The article aims to explain what sublimation ink is, its working process, and its diverse industrial applications. It is also crucial to understand the pros and cons of these inks in different sectors.

What Are Sublimation Inks Printing?

Sublimation ink is a specialized ink formulated to sublimate. It is not the same ink you use in your typical office printer. There are two types: aqueous sublimation ink dyes and solvent sublimation ink dyes. It is designed to directly change from a solid to a gaseous state when heated.

The specialized ink is made from dye particles and is specially made for a sublimation printer. The dye particles are suspended in a liquid carrier without dissolving. The complete definition of sublimation inks is based on the sublimation printing process.

How Do Sublimation Inks Printing Work?

The manner in which sublimation inks work is just amazing. This printing method is widely accepted due to its high-resolution images and designs. Sublimation inks are designed to be used with inkjet printers and are compatible with these special ink cartridges and their inkjet printing technology. The sublimation printer prepares the ink to print on heat transfer paper.

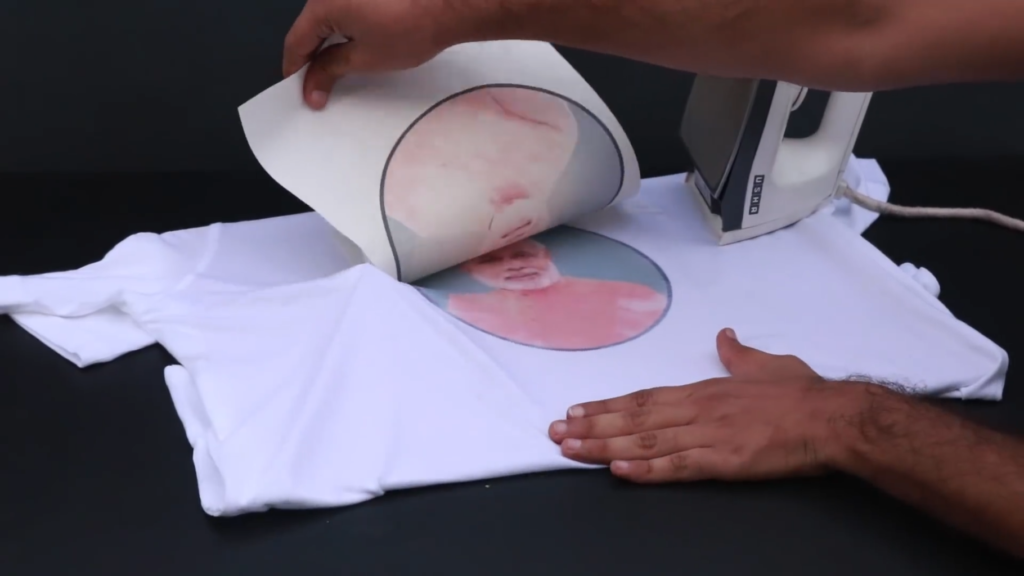

Once the image is printed on the sublimation paper by a digital printer, it is then transferred onto the fabric or print material. When the transfer paper is heated under pressure, the dye particles melt and change directly from a solid to a gas, diffusing and permeating the polyester fabric, creating high-quality print media.

Dye sublimation inks create reverse images on heat-resistant sublimation papers. The reverse images are then printed on polyester fabrics to produce the final print photos. This process is common when creating graphic designs on t-shirts. After printing, the ink becomes an integral part of the garment and does not fade over time.

Areas of Use – Industries and Applications

Sublimation inks come with a wide range of applications. The increasing reliability issues of screen printing have led to the use of sublimation printing technology because of its high-quality prints. With their unlimited advantages, sublimation printers have found their way into some key industries.

1. Textile Industry

Think of the attractive image and other prints in full color on your t-shirt. Textiles, like polyester garments, and apparel, like t-shirts, jumpers, and socks, are effective with sublimation printing. All polyester fabrics are compatible with sublimation inks. Notably, the textiles and apparel printed through dye sublimation are washable and do not wear or wash off over time.

2. Hardware

The demand for custom prints on personal items is high. Dye sublimation printing allows the creation of desirable images and other prints on hardware items like ceramics, metals, and wood. Some people also want to create personalized images on the surface of items like mugs and plates. The sublimation printing method can produce vivid designs on hardware items that can maintain vibrant colors even after washing.

4 Pros of Sublimation Ink Printing

Sublimation printing is a process in which ink is transferred from a printed piece onto a substrate, creating a permanent bond that won’t wash off or fade with time. Sublimation printing uses a special type of ink called sublimation ink. Here are some pros of printing with sublimation inks:

1. Detail on the High-Quality Images

Sublimation printers produce high-quality, sleek results. The sublimation ink reaches the printing material in gaseous form. It penetrates and firmly binds to the fabrics under controlled heat and pressure. The dye particles of the ink are embedded in the substrate and cannot fade off easily.

The sublimation process gives more detailed prints and high-resolution printing results. Unlike screen printing, where smudging and smearing pose a risk to image quality, sublimation printing is not affected by such factors.

2. Durability and Longevity

Sublimation prints have proven to be durable. Heat presses under pressure on the prepared heat transfer paper ensure the sublimation ink forms a firm image on the printing surface, including rigid surfaces of items like mugs and plates. The vivid image does not peel or scratch off and is close to permanent on the printed material, which is not the case with DTG printing.

Ready to Get Custom Packaging for Your Business?

start with a low minimum order quantity

For example, sublimation printing on garments can last longer without fading until the item is worn out. The sublimation inks are designed to be waterproof and resistant to UV, scratching, or abrasion over time.

3. Versatility in Material Application

One of the key advantages of sublimation printing is its flexibility with materials. The sublimation inks can print on a wide range of substrates, barring pure cotton or silk. You can use sublimation inks to print on polyester fabrics, wood, glass, cardboard, and metal surfaces.

Even the cotton, if treated with a polyester layer, can be sublimated with specialized ink. Business owners take advantage of sublimation printing since it can print on a wide range of materials.

4. Ease of Customization

The level of customization in sublimation printing is higher compared to other printing methods. It allows people to create near-permanent images and other graphics rather than adding layers on top of their items. It is ideal for quick customization and printing of personalized, intricate designs on mugs, apparel, and other items.

In today’s fashion markets, it is difficult to find garments without graphic designs; people are looking for clothing with the right fabric while looking attractive with designs. Even plain t-shirts or other garments on the market are sold without preprinted designs to allow customers to apply their desired graphics. The intricate designs will not peel as long as the print is applied effectively to the surface.

4 Cons of Printing with Sublimation Inks

While there are many advantages to printing with sublimation inks, there are also some cons to consider:

1. Initial Setup Cost

The initial cost involved in setting up sublimation printing is high. The cost of a sublimation printer is higher than that of a standard inkjet printer. In fact, special printers and inks are more costly than other printing methods. This is because the sublimation printer requires a special heat press machine, which increases the cost. This printing method is not cost-effective, especially when dealing with large quantities.

2. Limited to Polymer or Polymer-Coated Materials

Dye sublimation printers can only work with plastic substrates, especially polyester. All the printing materials must be coated with a layer of plastic polymer before printing. Dye-sublimation inks are not ideal for natural fabrics like cotton unless they are coated with a polyester layer before printing.

Ready to Get Custom Packaging for Your Business?

start with a low minimum order quantity

Materials polymer-coated with plastic polymers pose a risk to the environment. These materials produce solid waste, hindering sustainability efforts made by customers and businesses.

3. Complexity of the Process

The processes involved in sublimation printing are complex. From setting up the printing machines and preparing the transfer paper to heat pressing and producing a printed output, sublimation printing must be laborious. Heat-pressing each item individually and printing individual transfer papers makes the process tedious and complex. The repetition of these processes for individual items can also make sublimation printing slow.

4. Incompatibility with Certain Colors

The specialized inks in a sublimation printer cannot print on dark surfaces. Because the sublimation inks are transparent or sometimes translucent, they are only usable with white backgrounds and bright-colored objects. This incompatibility is a great downside for the application of sublimation printing.

Conclusion

Sublimation printing presents a suitable digital technology for vibrant-colored and quality designs. The sublimation inks come with excellent features that, upon printing, become a permanent part of the printed material. Also, the sublimation printer uses special technology to produce the desired quality output.

However, the sublimation ink comes with specific advantages and disadvantages that are crucial to getting started with sublimation printing. While getting started with your sublimation printing business, it is important to keep in mind your environmental goals.

Discover the Perfect Solution for Your Business with Packoi

Are you looking for packaging designs and printing solutions? Well, Packoi is a trusted company dealing with packaging designs and printing services. We have helped business people stand out from the competition with custom packaging designs and printing with our leading technologies.

Get your custom designs and printing today! Contact us or visit Packoi for more information.