Last Updated on April 22, 2025 by Packoi Team

Emboss printing and deboss printing are two techniques used to add texture and dimension to printed materials. These techniques are commonly used for business cards, invitations, book covers, and packaging.

In this blog post, we will explore the differences between emboss printing and deboss printing, the advantages of each method, the typical applications of both techniques, and the types of materials used for each method.

What Is Emboss Printing and How Is It Used?

Emboss printing is a printing technique that creates a raised impression on paper or other materials. This is achieved by pressing the paper against a raised metal die or plate, creating a three-dimensional design imprint. Emboss printing is commonly used for creating logos, patterns, and text on business cards, stationery, and packaging materials.

Common Applications of Emboss Printing

Emboss printing is a process commonly used for ink and is commonly used for business cards, logos, invitations, letterheads, packaging, and book covers. It is also a process used in the fashion industry for adding texture to leather and fabric.

What Are the Advantages of Embossed Printing?

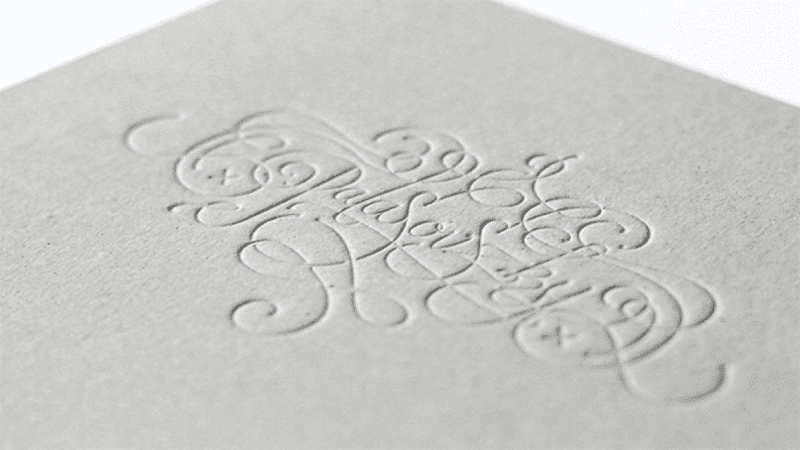

Embossed printing is a printing technique that involves creating a raised design or pattern on paper or other materials. The raised design is created by pressing a heated metal plate or roller onto the material’s surface. As the material cools, the design is left with a raised appearance. Here are some additional advantages of using embossed designs for printing:

1. Enhanced Logo Visibility and Legibility

Embossed logo designs are visually appealing and create a sense of depth and texture. This can help the logo design stand out from other printed materials and make it easier to read or for readers’ eyes to understand. Embossing can also highlight important information or create a sense of hierarchy within the logo design.

2. Durability and Longevity of Print Materials

Embossing adds an extra layer of thickness and resilience to the printed material, making it more resistant to wear and tear. This can be particularly useful for print materials, business cards, packaging, and other printed materials that are frequently handled or exposed to the elements.

3. Versatility

Emboss printing can be used on various materials, including paper, cardstock, leather, foil, metal, and plastic. This makes it a versatile printing technique that can be used for a variety of applications, from product packaging to wedding invitations.

4. Brand Recognition

Embossing and printing can be used to create a distinctive brand identity and help your business stand out from the competition.

By incorporating your embossed graphics, logos, or other design elements into your marketing materials, you can create a sense of professionalism and sophistication that will make a lasting impression on your target audience and potential customers.

5. Customization

Embossing allows for a high degree of customization, as the design of blind embosses and print pieces can be tailored to the specific needs and preferences of the client. This can include choosing the type of material, the size and shape of the embossed area of the print piece, and the design elements of registered emboss and printed pieces themselves.

What Is Deboss Printing and How Is It Used?

Deboss printing is the opposite of embossing printing images. Instead, blind embossing creates a raised impression, where an embossed image is printed, and a debossed image creates a depressed impression on paper or other materials.

This is achieved by pressing the paper against a recessed die or plate. Deboss printing is commonly used for creating logos, patterns, and text on business cards, stationery, and packaging materials.

What Are the Advantages of Deboss Printing?

Deboss printing is a printing technique that involves creating a depressed or indented design or pattern on paper or other materials. The design is created by pressing a heated metal plate or roller onto the surface of the material. As the material cools, the design is left with a depressed appearance. Here are some additional advantages of deboss printing:

1. Subtle and Elegant Appearance

Debossed designs have a subtle and understated appearance that can be ideal for minimalist designs. This makes it a popular choice for high-end and luxury products, where a simple and sophisticated look is desired.

2. Tactile and Visual Appeal

Like embossing and printing, debossing adds a tactile and visual element to the design. The depressed areas of the material create a sense of depth and texture that can make the design more memorable and eye-catching.

3. Durability and Longevity

Debossed designs are more durable and long-lasting than printed designs, as the ink in depressed areas is less likely to wear or fade over time. This can be particularly useful for business cards, invitations, and other printed materials that are frequently handled or exposed to the elements.

4. Versatility

Deboss printing can be used on a wide range of materials, including paper stock, cardstock, paper stock leather, metal plates, foil, and plastic. This makes it a versatile printing technique that can be used for a variety of applications, from product packaging to business cards.

5. Customization

The debossed printing area and embossed printing also allow for a high degree of customization, as the design can be tailored to the specific needs and preferences of the client. This can include choosing the type of material, the size and shape of the debossed printing area, and the design combination embossed on the elements themselves.

What Are the Common Applications of Deboss Printing?

Deboss printing is a popular printing technique that can be used for a variety of applications. Here are some common applications of deboss printing:

1. Business Card and Greeting Cards Made

Debossed business or greeting card stock and cards create a premium and professional look that can help your brand stand out. The tactile and visual elements of the debossed card stock and design can make a lasting impression on potential clients.

2. Invitations

Debossed invitations add a touch of elegance and sophistication to weddings, parties, and other special events. The depressed areas of the design can create a sense of depth and texture that makes the image of the invitation more memorable.

3. Letterheads

Debossed letterheads can help create a professional and polished image for your own business card. The subtle and understated appearance of the debossed design can help convey a sense of reliability and trustworthiness.

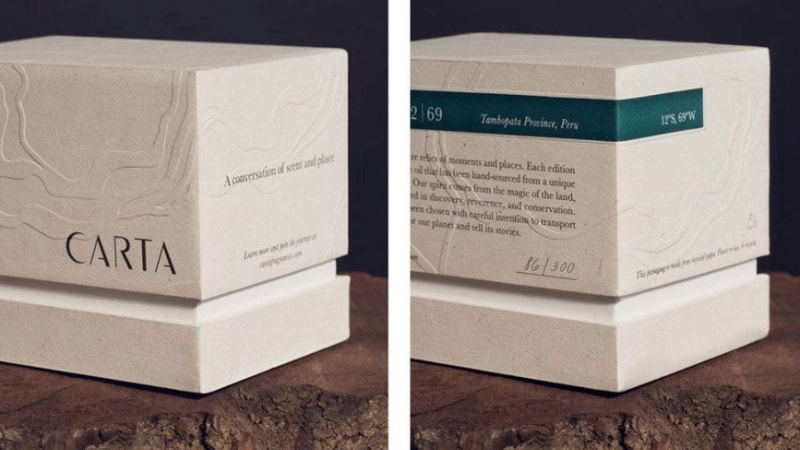

4. Packaging

Debossed foil packaging can help create a premium and high-end look for your products. The depressed areas of foil stamping in the design can create a sense of texture and depth, making your products more visually appealing.

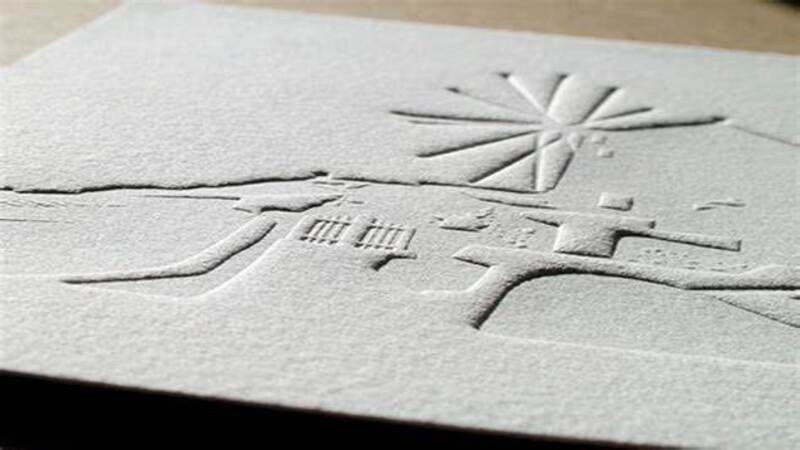

5. Book Covers

Debossed book covers can help create a sense of luxury and sophistication for your book. The depressed areas of the design can create a tactile and visual element that makes the book more memorable and eye-catching.

6. Fashion industry

Debossing is also commonly used in the fashion industry for adding texture to leather and fabric. It can create a unique and distinctive look that sets the final product and the brand apart from others.

What Are the Differences Between Emboss and Deboss Printing?

Emboss printing and deboss printing are similar techniques but produce different effects.

The main difference between the two techniques is the direction of the ink impression. Emboss printing creates a raised ink impression, while deboss printing creates a depressed impression.

Another difference between the two techniques is the types of materials that can be used. Embossing and printing work best with thicker papers and cardstocks, while the debossed area and printing process work best with thinner papers.

The cost of blind embossing, press printing, and deboss printing is also a factor to consider. Embossing and press printing are generally more expensive than debossing printing due to the complexity of the embossing process.

What Are the Common Materials Used with Embossing and Debossing Techniques?

Emboss printing, embossing, and debossing printing can be used with a variety of materials, including paper, cardstock, leather, and fabric. The choice of material depends on the desired effect and the project requirements.

Thicker papers and cardstocks are typically used for multi-level embossing and debossing, while thinner papers are used for embossing and debossing. Leather and fabric are commonly used for adding texture and dimension to fashion accessories and products.

Which Technique Is Right for You?

Choosing between emboss printing and deboss printing depends on the project requirements, budget, and desired effect. Emboss printing is ideal for creating a premium and professional look, while deboss printing is ideal for creating a subtle and elegant look.

The choice of material also plays a role in determining which technique to use. Thicker papers and cardstocks are best suited for emboss printing, while thinner papers are best suited for deboss printing.

Conclusion

Emboss printing and debossing printing are two popular printing techniques used to add texture and dimension to paper and other materials.

Both techniques have their advantages and are commonly used for business cards, invitations, letterheads, packaging, and book covers. Choosing between the two techniques depends on the project requirements, budget, and desired effect.

Get Your Exclusive Printing From Packoi Now!

If you’re interested in adding texture and dimension to your printed materials, consider Pakoi‘s embossing die, printing, or debossing die. Contact us today to learn more about our printing press and die services and how we can help you bring your ideas to life.