Last Updated on March 3, 2025 by Packoi Team

This article will look at corrugated paper and its different types, testing methods, application, eco-friendliness, and guiding tips for choosing corrugated paper.

What Is Corrugated Paper?

Also known as corrugated cardboard, it is a strong three-layered packaging material mainly used to make corrugated shipping boxes.

It comprises three layers; a single sheet of corrugated medium with flutes glued between two sheets of kraft papers or liners. The fluted material sandwiched between two sheets of liner board gives the corrugated board. You can create shipping boxes from this corrugated board capable of sustaining physical impacts during shipment.

Four Types of Corrugated Paper

As we know, the flute gives strength to the corrugated board; it is also important to note that it can be done at different levels to give types of corrugated papers with different strengths.

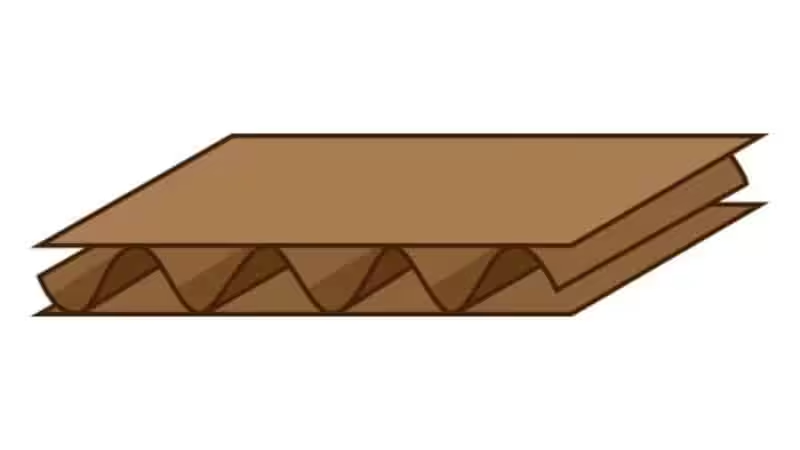

Single Wall Corrugated Paper

This basic corrugated board comprises two sheets of kraft paper or liner board with a corrugated material in between. This is what we call a “single-wall board,” and it is the most common in the retail market.

Single-wall corrugated paper is commonly used for retail displays and constructing packaging boxes. This is the most popular among people whenever they think about corrugated boxes.

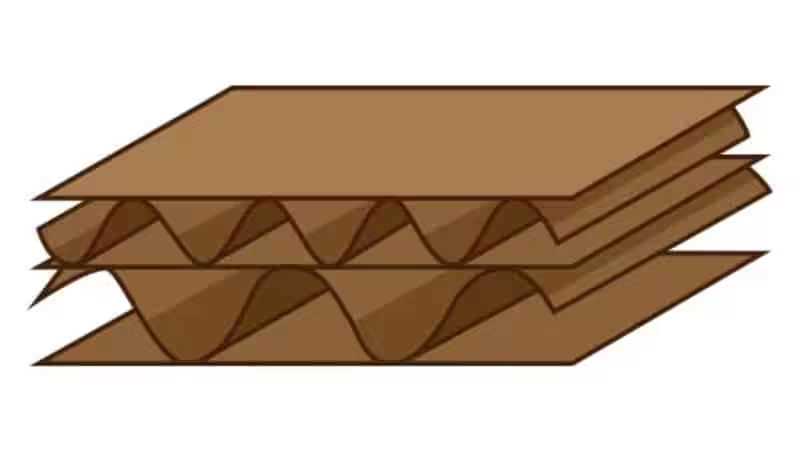

Double Wall Corrugated Paper

Suppose you attach a fluted sheet and an additional outer layer of liner or kraft paper in this order: liner-fluting-liner-fluting-liner. In that case, we end up having double-wall corrugated cardboard.

The double-wall material is more rigid and sturdy, making it suitable for heavy item packaging that is more delicate and may require extra protection.

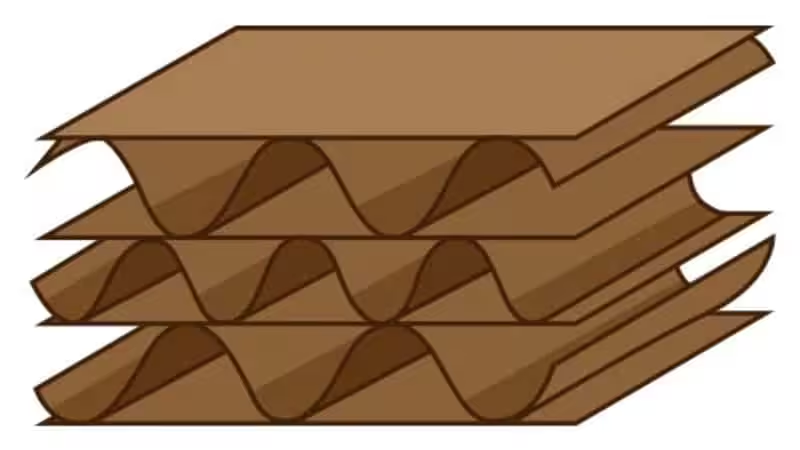

Triple Wall Corrugated Paper

If you are dealing with large and heavy items like auto parts, you need packages made of triple wall board. This comprises three stacked corrugated sheets and four liner board facings: liner-fluting-liner-fluting-liner-fluting-liner.

This is the strongest corrugated cardboard you can use to construct a corrugated box for shipping those heavy auto parts or industrial equipment.

Corrugated Fiberboard Boxes

Well, these are the packaging boxes constructed from corrugated fiberboards. Sheets of corrugated cardboard are joined with either glue or any joining component. You end up with a corrugated fiberboard box or a corrugated box in simpler terms.

These are the common boxes you see in retail shipping, and most probably, you recently received a product in a corrugated fiberboard box. Their main purpose is to protect items in retail packaging, securing them against physical damage during shipment.

What Is Corrugated Paper Flutes?

Flutes in corrugated papers refer to the c-shaped (or sometimes referred to as s-shaped) patterns forming the wavy layer in the corrugated board. The flute size influences the corrugated boxes’ rigidity, thickness, and stacking strength.

Flute types are identified by different letters that indicate their sizes. In corrugation, we have five common types:

- A Flute: This A-flute has a 1/4″ thickness with 33 flutes per linear foot.

- B Flute: A 1/8″ thick flute with 47 flutes per linear foot. The B-flute types are also thinner than the A-flute profile.

- C Flute: Being 3/16″ in thickness with 39 flutes per linear foot, the C-flute sheet of corrugated cardboard has exceptional compression strength as compared to the B-flute.

- E Flute: Extremely thin corrugated fluting with 90 flutes per linear foot, and measuring just 1/16″.

- F Flute: The narrowest type of flute profile. It has 125 flutes per linear foot and measures 1/32″ in thickness. Printed designs on this will be sharp thanks to its smooth surface.

Applications of Each Type of Flute:

- A Flute: Since this is the biggest and thickest flute type of fluted paper, it is mostly preferred to offer extra protection for fragile items.

- B Flute: It is one of the most common types for packaging purposes thanks to its surprising strength and exceptional versatility. B-flute is common for canned food items and counter displays.

- C Flute: It offers effective stacking strength and resistance to crushing and can be used for shipping boxes and packaging items like glass, dairy, and furniture products.

- E Flute: Not good for shipping purposes. As one of the thinner flute profiles, E-flute is sometimes a preferable option for making folding cartons instead of cardboard. Although it is thinner, the E-flute has excellent compression strength and crush resistance, and it can be used for cosmetic products, ceramics, and other lightweight delicate items. Due to its flat smooth surface, the E-flute offers high-quality printing applications.

- F Flute: Commonly applicable for clamshell boxes in the food industry. Also, the smooth surface allows for printing applications vital in food packaging.

What Are the Testing Methods for Corrugated Paper?

Now that you know what fluting, different flute profiles, and the wall types in corrugated cardboard, you also need some confidence that the box with your chosen flute grade and wall type can offer the required stacking strength and puncture resistance and, in the end, safeguard your products.

Depending on the retailer’s needs, corrugated boxes may be tested thoroughly. Let us look at the main testing methods for corrugated boxes:

Edge Crush Test (ECT)

Edge Crush Test (ECT) is a testing method for calculating the maximum compression force of a box, i.e., the amount of pressure a corrugated box can withstand before crushing. It involves the compression of the edges of the test paper between two plates. Edge Crush Test is expressed in pounds per linear inch.

Flat Crush Test (FCT)

The Flat Crush Test is a testing method used to assess the resistance of corrugated cardboard to the crushing of corrugated flutes. This test method loads a single corrugated wall board specimen perpendicular to its surface. The resistance to crushing presented by the corrugated board indicates its strength and how it will behave during packaging. It also helps determine the pressure that can be applied to the box process during printing application.

Minimum Puncture Test (MPT)

Also known as the Puncture Test, is a method used to measure the minimum pressure or energy required to puncture a corrugated board. In this test, with the help of a triangular or pyramid-shaped weight, the material is loaded in all spatial directions where a combination of compression, tension, flexural and shear forces take place.

Bursting Strength Test

This is a method for assessing the bursting strength of corrugated boxes before selecting them for packaging. The tester clamped with a round sample that applies hydraulic pressure (set using gauges), transferring equivalent pressure on the sides of the box. The pressure applied to bursting the sample can be used to calculate the bursting factor.

Bursting factor = Bursting strength (kg/cm^2) X 1000/grammage (gm/m^2)

Applications of Corrugated Paper

The corrugated board has many applications and is found in almost all industries. Corrugated paper is common because of its strength, effectiveness in safeguarding items, durability, recyclability, and environmental friendliness. Here are some of the key applications of corrugated paper:

Shipping Boxes

If you are considering shipping out items, you probably need corrugated shipping boxes. Corrugated boxes are approved for shipping because they offer great strength for accommodating items of varying weights. Every box has a specific quality and strength stamped on the surface.

Retail Packaging

Corrugated retail packaging is widely available in almost all retail outlets. Corrugated cardboard has proven to offer varying stacking strengths and can safeguard products. Retail corrugated packaging usually requires quality printing to display product features. Corrugated boards with E-flute have a smooth surface for high-quality printing, which serves well in retailing products.

Clamshell Packaging

Clamshell boxes made from corrugated cardboard and kraft paper are the ideal packaging for most takeaway and restaurant use. The corrugated material for this packaging is heat resistant; therefore, suitable and safe for microwave use for reheating food products.

The material is flat and smooth for printing applications, and you can leverage this with Packoi, which offers high-quality custom printing on your clamshell boxes.

Retail Point of Purchase Display

Retail display is like a store within a major store that allows your products to grab attention and stand out amongst competitors. The displays can be customized to fit your permanent or temporary needs.

Because of the fluted layer, the corrugated board offers excellent strength and can be customized into a display material with quality prints to drive sales. Some of the reasons why a sheet of corrugated cardboard is suitable for retail displays include its versatility, affordability, and adaptability.

Additional Packing Material

Bubble Wrap

Bubble wrap is made from 100 percent recycled corrugated board. It can be used as wrapping material for protecting items or as a filling material to cushion products from physical impact.

Foam Cushioning

A packing material that is made from a corrugated fiberboard material. The corrugated medium gives strength for cushioning and padding, while the smooth surface of the material protects items with delicate surfaces from scratching.

Packing Peanuts

The purpose of packing peanuts is to fill up void spaces, offer a cushioning effect, and safeguard items in shipping boxes from shock. More environmentally friendly packing peanuts made from biodegradable corrugated medium have been introduced recently as alternatives to the most common styrofoam packing peanuts.

Factors to Consider When Choosing Corrugated Paper

Packaging complements your products. As you consider the best material for your packaging solution, you probably desire material that subscribes to social responsibility in promoting sustainability, economics, and attractiveness. All these qualities can be found in corrugated materials.

Therefore, here are factors of corrugated paper to consider when choosing one for your packaging needs.

Stacking Strength

Stacking strength helps determine how much load a corrugated packaging can bear over shipping. Because of the varied fluting of the fluted material, corrugated cardboard comes in different stacking strengths. Therefore, choose a corrugated paper that offers the required stacking strength for your products.

Crush Resistance

This is the ability of corrugated paper to resist crushing when loaded. It is measured by loading the packaging box perpendicularly to its surface and indicates flute rigidity.

Since flutes have varied strengths to resist crushing due to different flute grades, choose a corrugated paper with the suitable ability to resist crushing to avoid crushing when items are loaded in the packaging.

Puncture Resistance

It refers to the ability of corrugated material to withstand internal and external forces to puncture. Your corrugated material should be able to withstand the compression, tension, and all forces when loaded and resist puncturing.

Flute Size

Flutes have different sizes (thickness), ranging from 5 mm to 0.8 mm. Choose corrugated cardboard with the ideal flute size depending on the weight and fragility of your items. Flute sizes include A-flute – 5 mm, B-flute – 3 mm, C-flute – 4 mm, E-flute – 1.5 mm, and more.

The most common flute size is C-flute, which is common in Regular slotted Containers like the half-slotted container. It offers excellent stacking strength, crush resistance, and durability.

Flute Grade

The grade of a fluted corrugated paper is determined by its grams per square meter (GSM) of kraft paper liner. The most common grades used include 115/125 gsm, 140/150 gsm, 185/200 gsm, 250 gsm, and 300 gsm. However, there is a wide variety of grades available.

Is Corrugated Paper Sustainable Packaging?

Corrugated paper is the most common material for any packaging box manufacturer out there. Corrugated fiberboard is one of the most eco-friendly packaging materials available. Packaging of corrugated paper can easily be recycled into something useful in the shipping line as well.

It can be recycled and used to make bubble wraps, packing peanuts, and cushioning foam in shipping boxes. Recycling and reusing corrugated paper can greatly help in reducing waste.

Conclusion

Corrugated packaging is the most common in every industry. This is because corrugated paper is versatile, cost-effective, strong, recyclable, and reusable. It can be used to make almost all types of boxes common in the market; regular slotted containers, folding boxes, or five panel folders, and more.

Most packaging and shipping boxes are made of corrugated material of different strengths. The corrugated material has proven to protect products and their quality well, cushioning the items from shocks during shipment.

Discover the Perfect Solution for Your Business with Packoi

Packoi is a socially responsible company, and in their call for the use of sustainable products, we advocate for corrugated packaging while helping businesses with custom packaging and printing designs that promote brand visibility without sacrificing the quality of the product. You can order custom printing applications for your corrugated packaging by contacting us here.