Last Updated on September 26, 2025 by Packoi Team

Businesses face a lot of costs, starting from product development to market research and advertising. One of these costs is packaging. The importance of packaging is such that it has become an enormous industry in itself.

Being a business owner or a major stakeholder, you need to be familiar with the different types of packaging and their respective costs to make an informed decision for your business. Below, we discuss the ins and outs of the packaging cost for businesses.

Factors Affecting Packaging Costs

Packaging cost is the total amount spent on getting a product ready for shipping and sale. This includes a variety of expenses, such as:

- Creating, designing, and producing the packaging itself.

- Purchasing raw materials.

- Paying for the labor involved in the packaging process.

- Shipping the packaging materials to your facility.

- Additional processing, such as custom printing or embossing.

Generally, there are many factors that affect the cost of packaging. These factors may impact everything from production costs to shipping costs. Here are some of them:

Type of Material

The material used to create product packaging is usually the biggest factor in determining its cost. For example, plastic packaging can be expensive due to its durability, while paper-based packaging tends to be more affordable. Similarly, materials like glass and metal can also be more costly.

Nowadays, more and more businesses are turning to sustainable packaging since it gives them a place in the consumers’ good books. In a McKinsey survey, over 60% of respondents said that they can pay more for a product with sustainable packaging.

Due to this, businesses have begun using alternative materials such as bamboo, bioplastics, and recycled paper. However, these materials are usually more expensive than their traditional counterparts. A plus point for using biodegradable packaging materials is that they incur lower shipping costs due to lower weight.

Sometimes, it’s just not possible to compromise on the type of packaging material due to the product’s nature. For example, fragile items would require sturdier packaging to avoid damage during transportation. In such cases, the cost of packaging material becomes a necessary expense that businesses have to bear.

Quantity and Economies of Scale

As a rule of thumb, the more packaging material you need, the higher your total expenditure will be. If you’re a big business that sells thousands of units, then it makes sense to purchase packaging material in bulk. The process is called economies of scale, where the cost per unit of packaging material decreases as the quantity increases.

Basically, packaging manufacturers offer pricing discounts on bulk orders. When you buy in bulk, you have the option to negotiate the rates and get a better deal. Plus, buying in bulk also helps reduce transportation costs as more materials can be shipped at once.

Customization and Design

The level of customization and design is also a factor that affects the cost of packaging. Customization could include unique designs, shapes, and sizes for your product’s packaging.

While this allows businesses to stand out from their competition, it also adds to the overall product cost. Also, intricate designs may require special machinery or labor, further increasing the cost.

Sometimes, custom packaging has less to do with what’s inside the box and more to do with creating a unique unboxing experience for the customer. For example, you may want the packaging material to be a specific shape or size. Perfume packaging boxes are a good example here. They usually have a particular shape and size to fit the bottle perfectly.

Printing and Labeling

Branding is an important part of creating a lasting impression on consumers. Besides your marketing collateral and website, you also want to brand your product packaging.

However, custom-designed packaging tends to be more expensive than generic options. The cost of custom packaging includes design fees, printing costs, and mold-making expenses. If you’re a small business with limited resources, this could be a significant investment.

The more complicated or extensive the design, the higher the cost will be. For example, if you only want the packaging to brandish your logo, it would be relatively cheaper than having a full-color design with unique shapes and materials.

The cost of printing also depends on the technology. Digital printing is ideal for small runs and intricate designs. However, it’s not as cost-effective for large quantities. In contrast, offset printing is better suited for high-volume orders and simpler designs.

Shipping and Handling

As we’ve touched upon, shipping also impacts the packaging cost. The higher the weight and the larger the size of your packaging, the more expensive it is to ship. Shipping carriers often use dimensional weight or volumetric weight when calculating shipping costs. So, a larger volume costs you more.

The shipping method also comes into play. Standard ground shipping is typically the cheapest option, while expedited and international shipping can significantly increase costs.

How far the manufacturer is from you also affects shipping costs. If the manufacturing facility is in another country, you’ll pay international shipping fees and customs duties. Local manufacturers are closer, so transportation costs are lower.

To reduce shipping costs, it’s best to go with corrugated boxes. They are lightweight yet sturdy and take up less space. It also helps to choose a manufacturer close to your location to lower transportation expenses.

Components of Packaging Costs

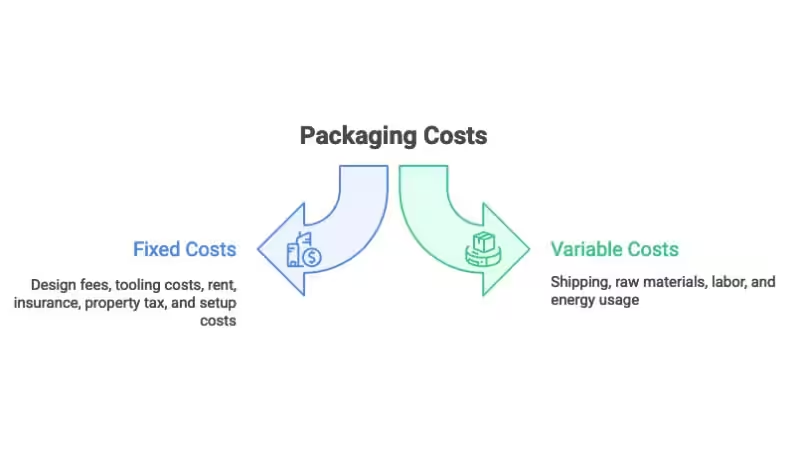

When it comes to packaging, there are two types of costs: variable and fixed costs. They differ in their relationship to production volume.

Fixed Costs

Fixed costs are the expenses that remain constant regardless of your packaging volume. These include:

- Design and tooling fees

- Mold-making expenses

- Rent for storage or facilities

- Insurance and property tax

- Machine setup costs

Typically, these costs are independent of the specific business activities of a business. You could be an e-commerce seller of essential oils or a retail store selling clothing. Both types of businesses normally pay the same fixed costs for packaging.

Variable Costs

Unlike fixed costs, variable costs change depending on your production volume. Examples include:

- Raw materials

- Labor

- Energy usage

- Shipping and handling fees

You should have a rough idea of how many units you’ll need to package for your business. It will help you estimate variable costs and determine if outsourcing packaging is cost-effective.

The Relationship Between Fixed and Variable Costs

The relationship between fixed and variable costs helps you gauge your business packaging costs. You know that fixed costs will stay the same irrespective of the production volume, but variable costs will increase. If you plan to factor the packaging cost into the total product pricing, you’ll have to base this increment on the variable cost.

Suppose your product costs $50. Of this amount, $3 is for packaging, and of this total, $1.5 is variable, and $1.5 is fixed. However, your product packaging supplier increases the shipping costs by $1. Now, the packaging costs go from $3 to $4, which translates to a $1 increase in the total product cost.

The example illustrates that even if fixed costs remain the same, an increase in variable costs will increase the overall packaging cost. You may want to now charge $51 for the product, up from $50, to make up for the extra $1 you’re spending on packaging.

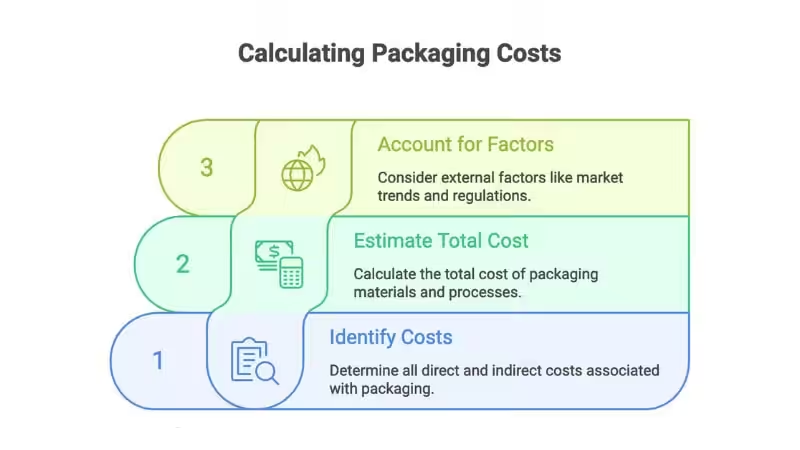

3 Steps to Calculate Packaging Costs

You must calculate packaging costs to decide how much to price your product and determine the profitability of your business. The following steps will help you calculate packaging costs.

Step 1: Identify Costs

Start by identifying the fixed and variable costs. You can refer to your packaging supplier invoice to see the total cost of packaging materials.

Step 2: Estimate Total Packaging Cost

Next, estimate the total packaging cost by multiplying the unit price of the materials by the number of units you need. Let’s say, in the first step, you determined that your total packaging cost was $3 per product. If you need 1000 units, your total packaging cost will be $3000.

Step 3: Account for External Factors

Add external factors to your packaging costs, such as handling fees, customs duties, and any other applicable taxes or charges. If you ship packaging from overseas, you’ll also have to pay to transport it from the point of origin to your business location.

You can use a packaging cost calculator to streamline these calculations. Order.co has a free calculator that accounts for both fixed and variable costs. Alternatively, use a self-made spreadsheet based on past relationships with suppliers and cost fluctuations.

3 Strategies for Reducing Packaging Costs

Every business wants to cut costs wherever possible. Here are some ways to lower your overall packaging costs.

1. Optimize Packaging Size and Weight

We’ve explained that the exact specifications of your product packaging can have an impact on costs. You can tweak the size and weight of packaging materials to lower their pricing.

For example, instead of buying bigger boxes for your products, you can find ways to optimize the items’ dimensions that will fit into a smaller box. You’ll not only save on the cost of the packaging material itself but also reduce shipping costs.

As for the weight, you could use lighter materials like bubble wrap instead of heavier options like Styrofoam peanuts. You may also switch to lightweight alternatives for your packaging materials, such as poly mailers instead of cardboard boxes.

2. Streamline Shipping and Handling Processes

A significant factor in packaging cost reduction is optimized shipping and handling. First, you can opt for standardized packaging sizes instead of custom sizes for your products.

You can further work with logistics partners to select the best shipping routes and schedules that minimize costs. Automation tools for shipping also help reduce the time and labor required for handling packages, thereby reducing costs.

3. Minimize Design and Printing Costs

If you opt for custom display boxes with extensive design and printing, your packaging costs will increase. You can lower this expenditure by using minimal designs.

Similarly, if you use dedicated packaging design services, the total costs will increase. Instead, use pre-built templates or free designs for cost reduction. You can go a step further and print your packaging in bulk to get discounted prices from printing companies.

Maximizing the Value of Product Packaging

Packaging is more than just a means of protecting and containing products; it also serves as a powerful marketing tool. Here’s how:

Enhance the Customer Experience

Customer experience begins with the product landing in the consumer’s hands. What’s the first thing they notice? The packaging.

Well-branded and well-designed packaging will help improve brand recall. It further improves customer satisfaction and leads to higher retention and loyalty. You can also use eco-friendly materials to appeal to environmentally conscious customers.

Highlight Product Features and Benefits

Product packaging also provides a peek into your product’s features. For example, Dae, a hair care brand, highlights its products’ premium ingredients on its packaging. Similarly, many food and nutrition-related brands also use food packaging to show that their product is non-GMO or gluten-free. Kellogg’s is a good example.

Besides adding value to the product, this also helps attract customers looking for these particular features. If your product has a unique set-up mechanism, you can also print instructions on the packaging material itself. The table shows some more options for using product packaging to its full potential.

These additions to product packaging help increase sales. They also make your brand more recognizable. For example, we can immediately identify the Nutella brand from its iconic glass jar with red and white labels.

| Feature/Benefit Printed on Packaging | Impact |

|---|---|

| Premium Ingredients | Attracts customers seeking quality products and builds trust in the brand |

| Awards or Certifications | Builds credibility and adds prestige to the product |

| Usage Instructions | Enhances user experience by making the product easy to use |

| Special Offers or Discounts (e.g., QR codes) | Drives immediate purchases and increases customer engagement through digital interactions |

| Iconic Visual Design | Improves brand recognition and loyalty |

| Nutritional Information | Increases transparency and fosters trust |

Measuring and Analyzing Packaging Performance

How do you know that you’ve perfected product packaging? You’ll need to measure its performance.

Track Packaging Costs and Metrics

Packaging costs tend to be dynamic, so it’s important to measure them regularly. Select appropriate key performance indicators (KPIs) like:

- Total Costs: The actual cost of the packaging material.

- Shipping Costs: The amount you spend to transport the packaging material to your warehouse or production facility.

- Storage Costs: The cost of storing the packaging material.

Another important metric is customer satisfaction. It’s a measure of how well the product packaging fits your customer’s needs and expectations. You could measure this through surveys or by tracking returns due to packaging issues.

Your financial accounting team can share their insights for this analysis. Work with them to see how your business’s cash flow has changed after making changes to the packaging material. If the numbers have improved, the packaging is doing the trick.

Analyze Packaging Data and Trends

When measuring packaging performance, don’t simply look at raw data. Instead, analyze trends to get a clearer picture of how your packaging is performing over time. You should also look at popular packaging trends in your industry to determine how you stack up against the competition.

Take notes from popular studies and industry reports. For example, Bain & Company releases an annual Paper & Packaging Report. McKinsey also releases paper and packaging reports that you can learn from. Use these resources to understand how you can further improve product performance with packaging materials.

Besides industry data, you can also monitor in-house packaging performance. Let’s say you use customer surveys to determine how satisfied consumers are with your products’ packaging. You can gain a lot of insights from this data.

For example, use data analytics tools like Tableau or Power BI to visualize trends and patterns in your packaging. Suppose you find that customers are happy with the size and material you’ve used, but they find the graphics to be dull. You can tweak your packaging design to make it more visually appealing.

Also, keep an eye on customer reviews. To monitor customer sentiment about your packaging, you can:

- Use online reputation monitoring tools

- Set up alerts for brand mentions with keywords like “packaging” or “product”

- Track how people describe your packaging in reviews and discussions

Monitoring these mentions will show you how people feel about your product packaging.

FAQs

Q1: What factors affect packaging costs the most?

Material type, customization, printing, shipping, and order quantity are the biggest cost drivers.

Q2: How do fixed and variable packaging costs differ?

Fixed costs stay constant regardless of volume, while variable costs change depending on production and shipping needs.

Q3: How can businesses reduce packaging costs?

Businesses can cut costs by optimizing packaging size, using lightweight materials, streamlining shipping, and simplifying designs.

Q4: What is the role of bulk ordering in packaging costs?

Bulk ordering lowers the cost per unit through economies of scale and can reduce shipping expenses.

Q5: How do you calculate packaging costs per unit?

Divide the total packaging expenses—including materials, labor, and shipping—by the number of units packaged.

Conclusion

To sum up, it’s imperative for businesses to understand their packaging costs and how they can impact the bottom line. From streamlining shipping processes to minimizing customizations and reducing material weight and size, a lot can be tweaked to reduce packaging costs. These strategies help businesses achieve the dual goal of boosting profits and keeping customers happy.

Reduce Packaging Costs With a Reliable Supplier

Are you on the hunt for a packaging supplier that helps you cut costs while offering top-notch quality? Packoi is a trusted supplier of custom packaging in bulk to meet your business needs. Get a quote today to improve your packaging performance.