Last Updated on September 19, 2025 by Packoi Team

Packaging is a transformative process that can potentially change the fortunes of your products and brand. Thanks to the global push towards environmental consciousness, materials such as glassine have been cast into the limelight and are now among the most sought-after packaging solutions.

In this article, you’ll learn everything you need to know about glassine paper, including how it is manufactured, its exceptional characteristics, and its applications. Additionally, you’ll learn about this packaging material’s key benefits and drawbacks to help you make a balanced choice when considering your packaging solutions.

What is Glassine Paper?

Glassine is a translucent, glossy paper made from wood pulp. Its unique appearance and exceptional structural barrier against air, water, and grease make it suitable for a variety of packaging applications.

Being 100% paper, glassine biodegrades completely, leaving no residues. Unlike plastic packaging, glassine is much simpler to recycle and has a longer useful life.

Whether you are looking for a classy protective cover for your delicate artwork or translucent paper for packaging, glassine gives you that and more.

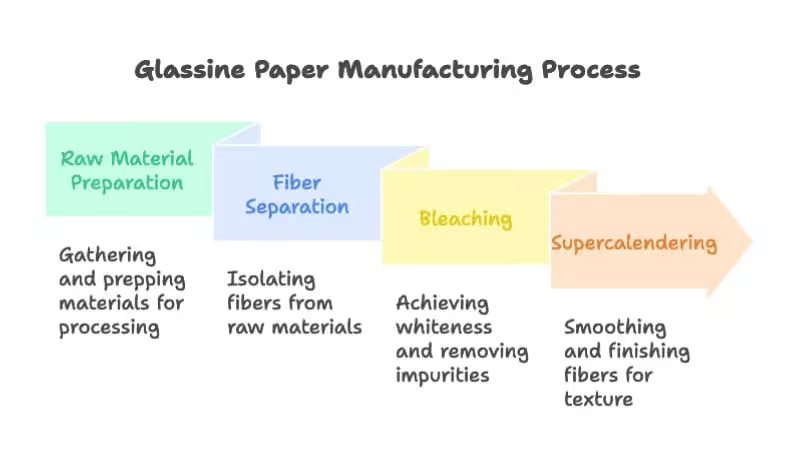

How Is Glassine Paper Made?

Glassine is an environmentally friendly, compostable film made from the pulp of hardwood trees grown in certified sustainable forests. Some tree varieties used include aspen, gum, oak, and birch.

When the trees mature, they are felled, and the logs are transported to designated factories or paper mills for pulping. The pulping and paper-making process can be broken down into the following steps.

1. Raw Material Preparation

Roundwood bolts are received at the pulp mill and debarked in large steel drums. Thereafter, they are either chemically or mechanically pulped. Chemical pulping involves chipping the wood, screening the chips, and cleaning them for the next process.

2. Fiber Separation

The goal of this process is to separate the fibers from the lignin. Lignin is a group of complex organic polymers that form the structure of cell walls in plants. If the lignin is not dissolved, it will react with the chemicals at the bleaching stage, making the paper brittle.

In chemical pulping, the fiber is separated by cooking the wood chips in a pressure digester using white liquor as the solvent for the lignin chemical bond. Once cooked, the digested pulp, also known as brown stock, is emptied into a blow tank where the volatile materials and the steam are drained.

Thanks to the dissolved lignin, the white liquor is usually black at this stage. According to industry practice, the black liquor undergoes a chemical recovery process and is returned to the digester as white liquor.

The brown stock, which looks like cooked oatmeal, is washed, screened, and cleaned to remove undigested fibers in preparation for the bleaching process. In mechanical pulping, the wood is fed into a grinder and turned into pulp through attrition. No chemicals are used.

3. Bleaching

Bleaching or brightening is necessary to complete lignin separation, remove any residue from the pulping stage, and produce light or white-colored paper. The bleaching agents include sodium hypochlorite, chlorine gas, oxygen, chlorine dioxide, and hydrogen peroxide.

The choice of bleaching chemicals and the sequence in which they are introduced determine the desired brightness of the paper. After bleaching, a moving wire cloth is used to drain the pulp.

It is important to mention that removing lignin leaves the fibers pH-neutral. This attribute makes glassine resistant to structural, optical, and chemical changes.

4. Supercalendering

This is the last stage in making glassine paper. To start with, the paper is taken through the standard calendering process. Here, heated or cooled pressurized calendars help to align the glassine fibers.

After that, the sheets are moved further in supercalendering, where a series of hard and soft-surfaced steel paper machine rollers apply pressure, friction, and heat to the fiber mat surface.

As the high-pressure rollers break down the capillaries, they improve the density of the glassine paper fibers, making them less porous. For this reason, the glassine becomes glossy and resistant to moisture, air, and grease. Additives may be introduced to give the glassine paper sheets the desired finish.

After this stage, the glassine paper sheets begin to be rolled and packaged.

The Key Benefits of Using Glassine Paper on Packaging

Using glassine paper is beneficial in many ways. Here are the most significant benefits:

Acid-Free and pH-Neutral

During the paper manufacturing process, lignin is removed at the pulping and bleaching stages. Chemically, the presence of lignin enhances acidity and leads to paper discoloration. Therefore, the acid-free nature of glassine paper ensures that it remains flexible, lasts longer, and retains its original color.

Strength and Durability

The density of glassine sheets, 40–90 gsm, is more than double that of other papers. This higher density gives glassine sheets remarkable tensile strength and endurance, which contribute to their long-lasting nature.

Recyclable

Since glassine is made of 100% wood pulp, it can be recycled many times. Ultimately, you can let it biodegrade without leaving any residues behind. With climate change and environmental degradation concerns taking center stage, having a fully recyclable packaging solution is a huge plus for the planet.

The Drawbacks of Glassine Paper

While glassine paper is a great packaging solution, you must be aware of a couple of challenges.

Printing Challenges

Due to its low ink absorption, printing on glassine paper takes a long time to dry. This also increases the risk of ink smearing on the print surface. That said, you can still do digital printing on the smooth, glossy glassine surface.

Embossing Difficulties

Glassine paper can be too wrinkled when embossing on surfaces such as folding carton paperboard or corrugated fiberboard.

Glassine Paper vs. Other Packaging Materials

Despite the few drawbacks, glassine paper offers many benefits and is of great utility in the packaging industry. As industry demands evolve, glassine paper becomes even more useful and a preferred packaging material. Its unique qualities and versatility make it applicable to almost all industries, from medicine to food to art.

Compared with other packaging materials, classine paper has its own characteristics. Here is how glassine stacks up against other packaging materials:

| Feature | Glassine Paper | Vellum Paper | Wax Paper | Cellophane | Parchment Paper |

|---|---|---|---|---|---|

| Texture | Smooth & glossy | Slightly rough & toothy | Waxy & smooth | Smooth & crinkly | Non-stick & smooth |

| Strength | High tensile strength, durable | Low, delicate and tears easily | Moderate | Thin, vulnerable to liquids | Strong & durable |

| Grease/Oil Resistance | ✅ Naturally resistant | ❌ No | ✅ Yes (from coating) | ✅ Yes | ✅ Yes (from coating) |

| Heat Resistance | ❌ No | ❌ No | ❌ No, wax melts | ❌ No | ✅ Yes, oven-safe |

| Recyclable? | ✅ Yes | ❌ No | ❌ No | ❌ No (complex) | ❌ No (silicone-coated) |

| Biodegradable? | ✅ Yes | ✅ Yes | ❌ No (takes very long) | ✅ Yes (but can release methane) | ❌ No (silicone-coated) |

| Best For | Eco-friendly packaging, art protection, food wraps | Commercial printing, overlays | Wrapping sandwiches, lining containers | Gift baskets, candy wrappers | Baking, roasting, non-stick cooking |

For a more detailed breakdown, here’s a closer look at how glassine compares to each of these materials individually:

1. Glassine Paper vs. Vellum

Vellum has been an industry standard for hundreds of years. It is translucent and mostly used for uncoated commercial printing work. However, in contrast to the smoothness of glassine paper, vellum is slightly rough and toothy.

Also, vellum is susceptible to tearing because it is more delicate and lacks the tensile strength that comes with glassine paper.

2. Glassine Paper vs. Wax Paper

As the name suggests, wax paper refers to paper that has been coated with wax to make it grease- and moisture-proof. As with plastic laminates, the major drawback of wax paper is that it cannot withstand heat and is, therefore, not safe when used in ovens.

Wax coatings take much longer to biodegrade and are not recyclable either. Glassine scores highly in both biodegradability and recyclability.

3. Glassine Paper vs. Cellophane

As a cellulose-based paper, cellophane is closer to glassine than other materials. It is a translucent paper that is resistant to oils and water. However, cellophane’s thinness makes it vulnerable to liquids.

Also, its production process utilizes toxic chemicals such as carbon disulfide, which can release methane if disposed of in landfills. This means cellophane cannot match the strength and eco-friendliness of glassine.

4. Glassine Paper vs. Parchment Paper

Also known as bakery paper, parchment paper is non-stick, heat-resistant, and grease-proof. It can withstand temperatures of up to 215 °C. The major undoing of parchment paper is that, unlike glassine paper, it is not compostable and cannot be recycled.

What Is Glassine Paper Used For?

According to Future Market Insights (FMI), glassine paper revenues are projected to hit US$4.99 billion by 2033, a 1.6X increase from 2023. The biggest markets are North America, Europe, and Asia, where users are keen to adopt safe, sustainable, and eco-friendly product packaging.

Glassine paper has multiple applications in a variety of industries. Some of the uses include:

1. Food Industry

Glassine comes in handy as a wrapper for meats and candies, and as a material for tear-resistant paper sheet covers and glassine bags. Because this acid-free paper has grease-resistance properties, it is used as a release line on cans and trays in baking.

2. Artwork and photography

Glassine paper is what you need to protect the surfaces of your paintings, photography, and processed films.

3. Bookbinding

Glassine paper’s acid-free, neutral pH makes it a suitable interleaving paper material. This application is important in protecting fine illustrations from rubbing against facing pages.

4. General Packaging

Other than food packaging, glassine paper comes in handy for packaging thanks to its high density and moisture resistance.

5. Philately

Postage stamps, postmarks, stamped envelopes, and postcards can easily become defaced if not handled with care. Using glassine envelopes, you can safely store your collections.

FAQs

Q1: What is glassine paper made from?

Glassine paper is made from 100% wood pulp through a process called supercalendering that makes it smooth and dense.

Q2: Is glassine paper recyclable and biodegradable?

Yes, glassine is fully recyclable, compostable, and biodegradable because it is made entirely from natural wood pulp.

Q3: Is glassine paper acid-free?

Glassine is naturally acid-free and pH-neutral, which makes it ideal for archival and protective purposes.

Q4: How is glassine different from wax paper?

Unlike wax paper, glassine is naturally grease-resistant without any coatings, making it recyclable and biodegradable.

Q5: Is glassine paper safe for direct food contact?

Yes, its purity and resistance to grease make it a popular and safe choice for packaging a variety of food products.

Conclusion

Glassine scores highly on the entire packaging spectrum. It is environmentally friendly and made through a process that poses no danger to the planet. Thanks to its rigorous production process, this packaging material is acid-free, durable, and can be used in various industries.

Get The Glassine Paper for Your Packaging With Packoi Today!

Are you looking for an FSC-certified glassine paper packaging supplier? Packoi Printing is here to meet all your needs. We are committed to the sustainability and responsible sourcing of our paper products. We have a strong design team to help you customize your packaging to reflect your brand equity.

Contact us today, and we will promptly respond with all the details you need and a quote.