Last Updated on October 20, 2025 by Packoi Team

Varnish coatings protect, enhance, and elevate the look and feel of your products. Turning ordinary prints into premium, high-impact visuals. With numerous varnish options ranging from glossy to textured finishes, selecting the right one for your business can be a challenging task.

In this article, we break down the varnish coating process, highlight its various types, and list their advantages and best applications.

What Is a Varnish Coating in Printing & Packaging?

Varnish is a clear wet ink applied to printed materials and packaging. It’s a protective coating made from a combination of resin, solvent, oil, and stabilizing agents. The varnish coating increases water resistance, repels insects, reduces the chances of discoloration, and protects from scratches.

There are several types of varnishes. We can broadly categorize these varnish coatings based on their solvent, finish, or application.

- Solvent – Water-based coatings that dry naturally. Ultraviolet (UV) coating that cures under direct sunlight or a UV lamp.

- Finish – Varnish can have a glossy, matte, satin, or soft-touch finish.

- Application – Flood varnish is the complete coverage of printed materials. Spot varnish selectively coats some areas of the printed surface.

We discuss these different types of varnish in more detail later in the article.

Protect Your Printed Materials & Packaging

Your product packaging is a visual representation of your brand. Scuffs, scratches, and water damage decrease the perceived value of the product and, by proxy, your brand.

Products often stay on store shelves for weeks or even months. Without varnish in packaging, the product boxes would wilt and degrade before the goods hit their expiry date. Packages with a protective layer have a clear advantage over non-coated competitors.

Enhance Packaging Appeal

Now that varnish coating machines have become affordable, businesses are trying to differentiate themselves based on varnish application. Packaging varnish has become a design tool that protects and enhances your product packaging.

Businesses use varnish coating to change the look and feel of their packaging. Satin or soft-touch coatings give your products a premium and luxurious vibe. At the same time, gloss varnish in packaging is mostly used to gain customer attention. A high-quality varnish coating helps your products stand out and boosts product sales.

9 Types of Varnish Coatings in Packaging & Printing

Varnish is just another tool in your branding arsenal. Your choice of varnish will affect the overall look, feel, and presentation of your packaging.

Here are 9 types of varnish coatings that will take your packaging to the next level.

1. Gloss Varnish Coating

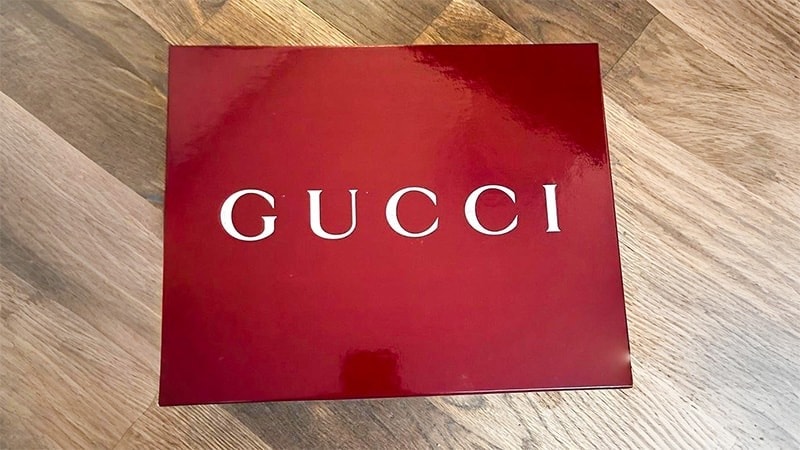

Gloss varnish coating is the most standard option. Cover the entire surface in a clear liquid that becomes reflective after drying. It’s a cost-effective way of protecting and enhancing your products.

The glossy finish enhances prints by giving colors a more saturated look. It gives packaging a smooth touch and a shiny, polished texture. You can find glossy finishes on business cards, brochures, product boxes, and other promotional materials.

This type of varnish reflects light at a sharp angle, resulting in a white glare over the packaging. Gloss varnish makes products more appealing in person. However, it loses its edge in photography, especially when using a camera flash.

Since gloss varnish is so reflective, it reflects every scratch, crease, and dent in the packaging.

Advantages

- Affordable Protective Layer

- Boost Packaging Color Contrast

- Better Store/In-person Presentation

Disadvantages

- Poor Visibility under Direct Lighting

2. Matte Varnish Coating

Matte varnish is the exact opposite of gloss varnish. Instead of reflecting light, it disperses it across the product surface. The final result is somewhat dull print colors, but superior readability.

High gloss coating is inconsistent. It changes your product’s appearance based on lighting conditions. By comparison, matte varnish ensures product appearance, stays consistent across photos, videos, store displays, and in customers’ hands.

Unlike gloss UV coating, which can feel cheap, matte varnish has a unique, soft, and premium feel. It’s also more expensive than the standard gloss finish. Since every brand uses gloss coating, a matte finish will help your products stand out from a row of reflective product boxes.

The softer look of matte varnish makes it ideal for luxury products and cosmetic packaging.

Advantages

- Soft & Premium Feel

- Consistent Product Presentation

- Unique Packaging Appearance

Disadvantages

- Dull Print Colors

- Higher Cost

3. Satin Varnish Coating

Satin varnish is a hybrid of matte and gloss varnish. It’s ideal for brands that want good in-store presentation but want to avoid harsh glares.

Many packaging printers market satin varnish as a gloss finish and other reflective varnishes as a high gloss finish. Satin finish is commonly used for product packaging that will interact with the customers. Hence, beverage packaging commonly uses a satin or suede varnish.

Similarly, magazines and cookbooks use satin varnish pages to protect them from finger smudges while ensuring good readability.

Advantages

- Better Light Distribution than Gloss Varnish

- Better Color Contrast than Matte Varnish

Disadvantages

- Less Bright Colors than Gloss Varnish

- Less Premium Feel than Matte Varnish

4. Soft-Touch Varnish Coating

Soft-touch coating is a variation on matt varnish. It gives your packaging a soft velvety texture. The tactile feel of soft-touch varnish solidifies your product’s status as premium and luxury.

Other varnishes are designed to sell products from their packaging. It’s a key component of using packaging design as a marketing tool. However, soft touch varnish is the opposite.

Luxury products are sold based on their story, performance, and design. After the sale, consumers expect the packaging to reflect the contents inside. Soft-touch varnish is used on boxes for expensive tech products, luxury watches, jewelry, and premium cosmetic packaging.

Advantages

- Premium Feel that Matches Luxury Goods

- Soft Tactile Surface Finish

- Elegant Package Design

Disadvantages

- Very Expensive

5. Strike-Through Matte Varnish Coating

Strike-through matte varnish is a glossy coating that is applied to a matte finish base. It’s a unique blend of matte and gloss coating that creates visual appeal. As light reflects off the surface, the gloss parts shine while the matte parts stay the same.

The name comes from the varnish application process. A base matte finish is first applied to the printed materials. Then a gloss varnish is applied on top, and it “strikes through the matte surface“.

Strike-through varnish enhances product presentation. It gives your packaging a 3D look. Brands use a matte finish for the background colors and gloss finish on logos, images, and titles.

Advantages

- Creates Visual Interest

- Enhance Surfaces

- Shiny Elements on Packaging

Disadvantages

- Time-Consuming Design

- Slightly Expensive

6. UV Coating

UV-based varnish is a unique protective and high-impact-resistant coating. It is applied like paint over the printed materials and cured using ultraviolet light (UV) drying lamps.

Other varnishes are thinner and quicker drying, so they are printed on the packaging, similar to color printing. However, UV coatings are more viscous and are applied using roller drums. It takes a long time to cure (harden). So a UV light is used to mimic the natural wavelength of the sun.

Compared to other types of varnish, UV results in more durable packaging. The packaging industry highly favors UV coating for its convenience.

Paired with wet trapping, a printing process that quickly layers a UV coating on top of wet ink for speed and efficiency. Afterward, the entire surface is dry-cured using UV light.

Gloss UV coating is more difficult to scratch, making it an ideal finish for business cards that see a lot of wear and tear.

Advantages

- Better Durability

- High Gloss Finish

- Affordable

Disadvantages

- Time-Consuming Design

- Poor Visibility under Direct Lighting

7. Spot Coating

Spot varnish or spot UV printing is a unique package design tool. The liquid coating selectively covers sections of a packaging material. It’s similar to strike-through matte varnish, except that there is no requirement for a base matte varnish.

Packaging designers use spot gloss varnish to highlight logos, images, and other design elements so they pop from the background.

In standard UV coating, the printed piece passes through two drums that coat the entire sheet in UV resin. This process is called flood coating or flood varnish.

In spot coating, the spot UV pattern is printed on like ink and cured using UV. It’s a highly precise process that requires a unique printing press.

Advantages

- Better Durability

- Highlight Select Design Elements

- Creates Visual Intrigue

Disadvantages

- Slightly Expensive

8. Raised UV Coating

Raised UV coating is a subcategory of the spot UV printing process. This process uses a thicker layer of transparent coating that results in a raised tactile texture. When done right, raised UV coating can create some truly unique packaging designs.

It is also one of the more expensive print coatings. Hence, its applications are limited. You can use raised UV coating on premium business cards and packaging material for high-cost items.

You can also use raised UV for accessibility applications. Adding a tactile bump enables visually impaired individuals to read the text.

Advantages

- Tactile Texture

- Highlight Select Design Elements

- One of a Kind Texture

- Improves Accessibility

Disadvantages

- Very Expensive

9. Aqueous Coating

Aqueous (AQ) coating is a water-based protective layer applied to printed materials. It’s available in gloss, matte, and satin finishes. It provides basic protection against smudges and scratches.

It’s the second most common type of protective coating after gloss resin. It’s generally used for low-cost items such as cardboard burger boxes for fast food restaurants.

Aqueous coating is known for two distinct properties. It’s fast-drying and one of the few eco-friendly varnish options. Sustainable packaging solutions are in demand right now. More and more businesses are switching over to environmentally friendly packaging.

While AQ coatings aren’t the most attractive solution, they’re affordable, reliable, and better for the planet.

Advantages

- Cost Effective

- Environmentally Friendly

- Available in Matte and Gloss Finish

Disadvantages

- Basic Protection

Comparing Every Print and Packaging Varnish Option

Now that we have a good understanding of the different varnish coatings. Let’s compare them head-to-head against each other.

| Varnish Type | Cost | Durability | Texture | Drying Time | Environmental Impact |

|---|---|---|---|---|---|

| Gloss Varnish | Low | Great | Shiny | Fast | Moderate |

| Matte Varnish | Medium | Great | Soft | Moderate | Moderate |

| Satin Varnish | Medium | Great | Semi-Soft | Moderate | Moderate |

| Soft-Touch Varnish | High | Great | Velvety | Slow | Moderate |

| Strike-Through Matte | High | Great | Mixed | Slow | Moderate |

| UV Coating | Low | Excellent | Very Shiny | Fast (UV-cured) | Moderate |

| Spot Coating | High | Great | Shiny Accents | Fast (UV-cured) | Moderate |

| Raised UV Coating | Very High | Great | Raised Surface | Slow | Moderate |

| Aqueous (AQ) Coating | Low | Good | Shiny | Fast | Eco-Friendly |

A quick glance shows us that there is a shortage of eco-friendly varnishes. All varnishes contain some type of plastic resin or polymer that makes the packaging hard to recycle.

We can also see that plain glossy coatings are the most affordable and offer decent protection and durability. Soft-touch, spot, strike-through, and raised varnishes are generally limited to premium packaging materials.

Matte varnish with a soft finish strikes the ideal balance between visual appeal and functionality.

Varnish vs. Lamination: Choosing the Right Finish

Another packaging protection option we haven’t discussed is lamination. It’s a great alternative to varnish for select applications. Here is a quick breakdown of all the ways lamination differs from varnish.

Varnish: Lightweight Coating for Short-Term Protection

Varnish is a liquid coating applied on top of a printed surface to enhance appearance and provide temporary protection. Unlike lamination, varnish is thin and doesn’t add extra weight to the packaging material.

It’s a short-term packaging protection solution. It only needs to keep the products safe until the sale is finalized.

A key advantage of varnish is its precision. It can be selectively applied to highlight specific areas, logos, or text. Spot and strike-through varnish are ideal for creating visual contrast and tactile effects without fully covering the surface.

Lamination: Durable Plastic Layer for Long-Term Protection

Lamination involves fusing a thin sheet of plastic onto a printed surface, creating a stronger, more durable layer. It not only safeguards the design from moisture, wear, and tear but also gives the material a semi-rigid structure.

Commonly used for book covers, cards, certificates, and premium packaging, lamination is ideal for applications that demand longevity. It is best suited to high-end packaging such as jewelry or ring boxes that double as display containers.

FAQs

Q1: What is the Best Varnish Coating for Packaging?

UV-cure varnish is the most durable coating for printed materials and packaging.

Q2: Are Varnish Coatings Waterproof?

Yes, varnish coatings are waterproof. They form a clear protective layer over your packaging designs.

Q3: What is the Difference Between Varnish, Epoxy, and UV Coating?

Varnish is a thin coating, and epoxy is a thick coating. UV varnish is a thin liquid coating that dries under UV light.

Q4: Is Wood Varnish Different from Print Varnish?

Yes, wood varnish is oil-based and has a yellow tint. Print varnish is transparent with either water or resin-based.

Conclusion

Varnish is an integral part of modern packaging designs. It protects your prints from environmental effects and adds a flair of style. A well-executed varnish coating can leave a lasting impression on the consumer. Today, matte and spot UV coating are considered the gold standard for premium clear coatings. Use the information from this guide to choose the right varnish for your business.

Get Varnish Coated Custom Packaging from Packoi!

Packoi is a premier manufacturer and supplier of high-quality packaging and print materials. We specialize in fully custom product boxes and bags. Get your desired packaging with your choice of varnish coating.

You can also work with our design team to fine-tune your spot varnish packaging printing. Contact us now!