Last Updated on March 19, 2025 by Packoi Team

Understand what each refers to while appreciating their advantages and disadvantages.

The printing industry is gradually developing. Several market drivers, such as cost management, market demand, sustainability and environmental challenges, product diversification, and more, are impacting the printing sector from all angles.

These drivers also influence the kind of ink and printing technology required to meet market demands.

In the modern market, where sustainability is a key driver, companies and consumers have committed to keeping the environment safe. So, it is necessary to look for environmentally friendly, efficient, and cost-effective printing and coating technologies in the printing market.

This has led to increased interest in understanding the capabilities of water- and solvent-based inks. Both the two inks have pros and cons depending on where each is applied and your specific needs.

This article will describe in detail water- and solvent-based inks, look at their different pros and cons, and make a comparison of the two inks based on key factors like cost-effectiveness, environmental and health concerns, kind of output, and performance.

The blog will act as a guide for ink selection for anyone considering starting printing projects.

What Are Solvent Inks?

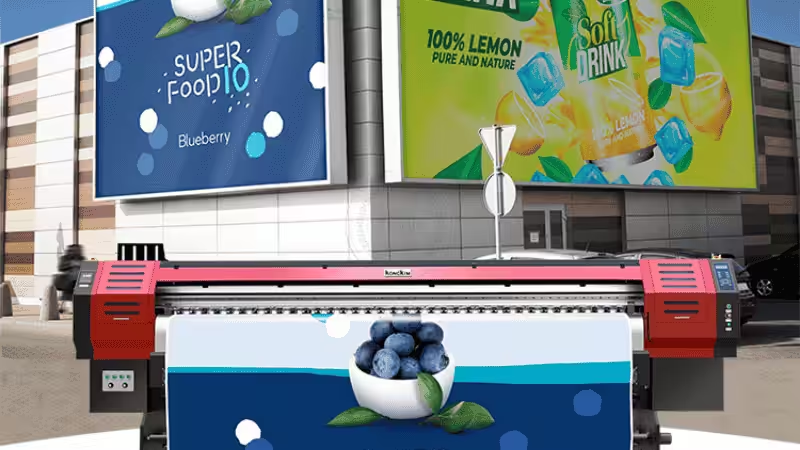

Solvent ink refers to printing ink made of various oil-based solvents (volatile organic compounds). This kind of ink is used for a wide range of printing solutions thanks to its capability to print on unlimited surfaces. Solvent-based inks are popular in the printing market due to their amazing print quality.

Also, these inks are relatively cheap and compatible with inkjet printers. The solvent-based ink is water-resistant due to its high level of organic solvents. The ink is formulated to offer a faster evaporation rate when drying, delivering superior results and value, especially in large-scale printing where speed is crucial.

Normally, the level of volatile organic compounds (VOCs) in solvent-based inks is 100 percent, and this enhances press efficiency with high press speed. Notably, solvent-based printers are generally faster at producing prints than their water-based counterparts.

Solvent-based printing is commonly used in commercial settings where speed, efficiency, and output are key factors in meeting market needs.

Pros of Solvent Inks

Solvent ink is a commonly used ink that has obvious advantages, and the following are the main advantages:

1. Durability and Longevity

When it comes to print output, ink durability and longevity are crucial. You do not want your printed image to fade and lose its attractiveness. And that’s what oil-based inks offer: durability. Solvent-based ink offers high durability, even in extreme environmental conditions.

The prints can averagely last for 5 years without discoloring while resisting abrasion. Because of its ability to resist abrasion and discoloring, solvent-based ink lasts longer on the printed surface.

2. Outdoor Suitability

Generally, solvent inks offer outdoor suitability thanks to their unrivaled features. One of the important factors is their ability to resist extreme environmental conditions. Solvent-based inks have high resistance to high temperatures and scratching, which are common in outdoor settings.

Also, because the inks have a high content of oil-based carriers, they are waterproof, making them tolerant and resistant to moisture without fading. These attributes make ink solvent suitable for outdoor applications like banners and roadside signage, where weather conditions vary from time to time.

3. Versatility on Different Materials

Solvent inks are quite flexible and versatile. They are formulated to work on non-absorbent or non-porous media, including uncoated surfaces. Oil-based inks can be used to print on a variety of substrates, such as metal, plastic, glass, varnished surfaces, foils, and glossy paper or cardboard.

With the high demand for advertising banners and personalized prints on personal items, solvent-based inks offer the best solutions. The inks also have many applications, including packaging printing, graphics, marking and coding, labeling, billboards, vehicle wraps, and more.

So, you can use these inks in different applications and industries.

Cons of Solvent Inks

But everything has its shortcomings; solvent ink is no exception. it has some aspects of shortcomings that need you to understand.

1. Environmental Impact

Oil-based inks have volatile organic compounds (VOCs) or solvents that evaporate in the form of chemical fumes during the drying process. These hazardous substances have a detrimental impact on the environment by causing ozone pollution.

While using these inks, it is advisable to have the right containment and environmental protection measures against hazardous VOCs.

2. Health Considerations

The substances produced during printing, especially during the drying process, cause severe health problems. Solvent-based inks produce hazardous substances that cause skin and eye irritation.

When inhaled, ink fumes and odors may cause asthma, respiratory problems, and, in severe cases, organ cancer. In fact, oil-based ink cartridges have logos indicating the substance’s health risks.

3. Need for Special Ventilation and Waste Disposal Systems

Exposure to the evaporated solvent substance causes both health and environmental problems. At the printer station, the level of fumes and odors is high. There’s a need to reduce exposure to these substances for the printer and customers through special ventilation.

Proper venting will allow the fresh air to dilute volatile compounds and exhaust, allowing the vapor to escape the room without exposing people to health risks. Also, a proper waste disposal system is essential to reducing environmental damage from hazardous waste.

What Are Water-Based Inks?

In water-based inks, water is the main solvent. But water is not the only solvent; most of these inks contain “co-solvents” that are crucial in curing. Water-based inks are ideal in situations where a “soft hand” is needed.

Because of the environmental and health problems of solvent-based inks, water-based ink entered the market as an environmentally friendly ink. Consumers are becoming eco-conscious, and so are businesses, becoming more active in sustainability efforts.

Businesses are under pressure to enhance production efficiency while ensuring their working environment remains safe. So, what are the pros and cons of water-based ink?

Pros of Water-Based Inks

Water-based ink is a relatively environmentally friendly ink that has its advantages and disadvantages. The following are its advantages:

1. Environmental Friendliness

Water-based ink does not contain VOCs or any other toxic chemicals. This means ozone pollution is much lower with water-based ink compared to solvent ink.

Water-based inks are made of natural materials and are easily recyclable and reusable. There is less waste to the environment and, so, an eco-friendly business ecosystem.

2. Safety and Health Considerations

Water-based ink is non-toxic and contains no volatile solvents that may cause harm to people. While working with water-based ink, there is no risk of exposure to fumes and odors.

Therefore, health risks are reduced in water-based ink than in conventional solvent pigments. Waste in water-based printing is non-hazardous.

However, catalyzed water-based ink should be handled as hazardous and should be disposed of as harmful waste.

3. Ease of Cleanup

Cleaning up water-based ink is easier than oil-based ink. You can use water to clean the ink, but as the water evaporates, cleaning becomes difficult. Therefore, a screen cleaning system is recommended to capture the water-based pigments. No solvent is required for cleaning.

Cons of Water-Based Inks

Relative to solvent ink, water-based ink also has its shortcomings.

1. Limited Durability Compared to Solvent Inks

The durability of water-based ink on fabric is limited. Water-based ink is not waterproof, making it prone to decoloration and fading. These inks have lower resistance to chemicals, water, and heat than their solvent-based counterparts.

2. Not as Suitable for Outdoor Uses

Because water-based inks are not waterproof, they are prone to smearing and abrasion, which reduces color consistency and contrast. Also, they are less resistant to extreme environmental conditions, like high temperatures, which may damage their resolution.

3. Can be Problematic on Certain Materials

Water-based inks are limited to printing on a few absorbent substrates. It is problematic to print non-porous materials like metal, glass, plastic, and some glossy surfaces. This is because water-based ink needs to penetrate the fabric or surface to effectively create an image.

Solvent Inks vs. Water-based Inks

Let us compare the two inks based on:

1. Cost Implications

Water-based inks are relatively cheaper than their solvent-based counterparts. Also, the cost required to operate solvent-based printing is higher than for water-based technology. The costs of venting and waste management in solvent-based settings are eliminated in water-based printing.

Therefore, water-based ink is cheaper for purchasing, waste management, and storage than its solvent-based counterpart.

2. Environmental and Health Considerations

Solvent-based pigments contain harmful VOCs and emit more waste into the environment. Evaporation of the organic compounds during the drying process emits ozone pollution and toxic chemicals. The toxic chemicals cause detrimental health problems.

On the other hand, water-based inks are made of natural substances that do not pollute the land and have no detrimental health effects.

3. Quality and Performance

Oil-based inks dry faster and are resistant to water, heat, abrasion, and fading, producing classy output. The slow drying of water-based ink and its high surface tension cause smudging and smearing.

The slow drying consumes more energy, which means water-based ink prints are dull, the process is not efficient, and it is not cost-effective, especially in an industrial setting.

As a result of fast-drying and high-resolution images, solvent-based printing is more efficient than water-based pigment.

Conclusion

If your printing does not demand a quick turnaround, water-based ink could be a better option. It provides more sustainable solutions with fewer health risks. However, the application of water-based ink should be carefully done because of its output issues.

Although ditching solvent-based ink for water-based ink comes with a sacrifice in output and efficiency, it is worth it considering the environmental gains.

Discover the Perfect Solution for Your Business with Packoi

At Packoi, we are committed to delivering exceptional packaging design services that meet market demand while taking advantage of the opportunity to advocate for environmental sustainability. Get design services today to spice up your packaging. Contact us or visit us at Packoi for more information.