Last Updated on August 25, 2023 by Packoi Team

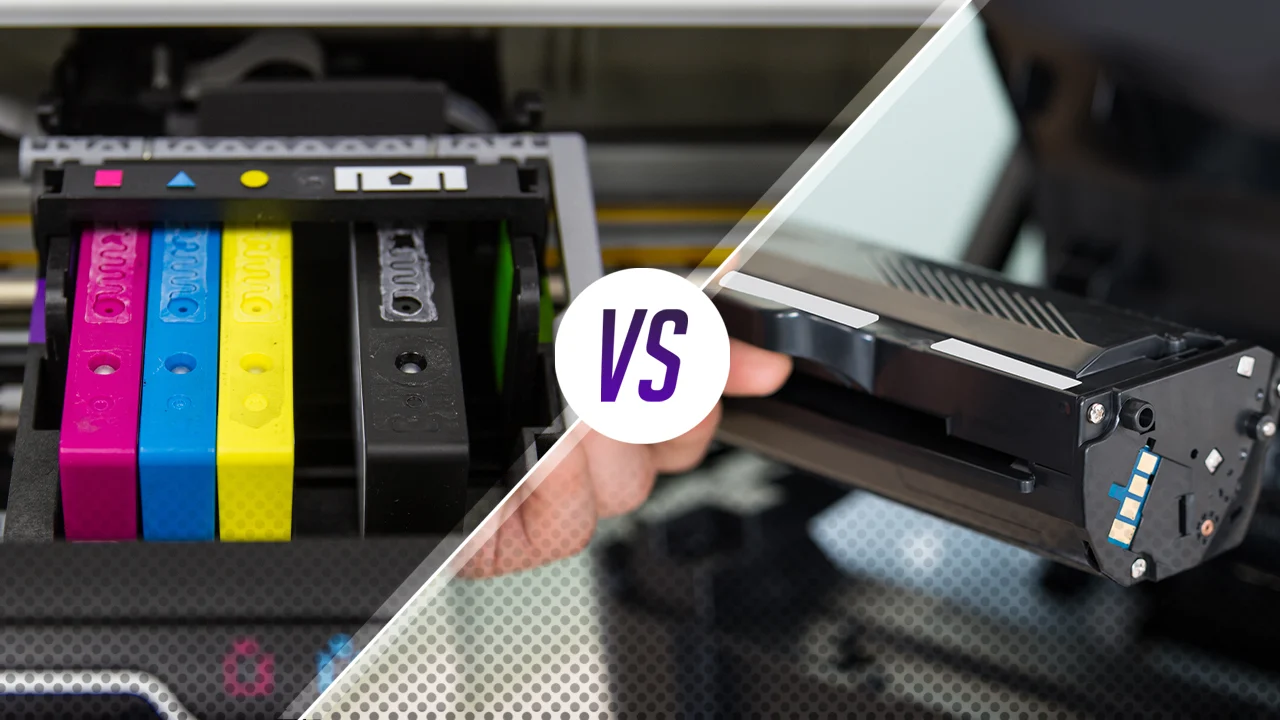

In this blog, we will look at how laser and inkjet printers work, each of their key components, compare them, and provide guiding tips to help you acquire the best printer for your needs.

How Do Laser Printers Work?

A laser printer uses toner powder instead of dye or ink to create text and images. It is generally larger and more durable than conventional printers and is commonly used in office settings for higher-volume production. Over the years, these printers have evolved into efficient machines in offices and printing stations. There are three types: monochrome, color, and multifunctional laser printers.

Overview of Laser Technology

Laser printers use electrophotographic processes to produce texts and images. It involves a laser beam of light with precise wavelength and electrostatically charged dots attracting toner on the photosensitive drum, creating images on the photosensitive drum and onto the paper. After the particles form the required image, fusing occurs under controlled heating and pressure to fuse the particles firmly on the fabric.

Key Components of a Laser Printer

Laser printers are common in many office settings due to their print speed. Each consists of eight primary components, each playing a crucial part in producing high-quality images. These include:

- Power supply – this printer requires a high-voltage power supply for charging the drum and corona wires for the transfer process.

- Laser – the laser section transmits light from the diode across mirrors and reflects it on the drum unit to imprint the shape of your print.

- Photosensitive drum – for attracting particles from toner cartridges on the beam-exposed surfaces, turning it into the latent image that creates a final image when the toner meets the substrate.

- Toner cartridges – for holding the powdered substance used as an imaging agent in this printer.

- Corona wires – the main corona wire positively charges the photosensitive drum. The transfer corona wire has a negative electrostatic charge and is responsible for negatively charging the paper.

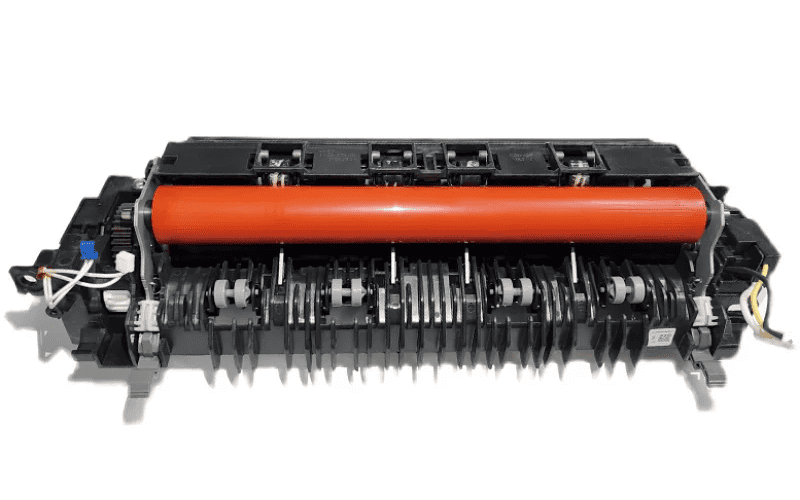

- Fuser unit – with two hot rollers, the fuser uses high heat and pressure to melt and strongly fuse the particles onto the fabric. The fuser unit operates at a higher speed. Thus, the sheet makes little contact with the paper, preventing the risk of burning the transfer sheet.

- Transfer belt- its purpose is to move the paper through the printer, pass it through the drum where the image imprint is fused on the substrate, and eject it afterward. However, some small printers have rollers instead that work as the belt.

- Waste toner bottle – used for collecting excess particles from the drum unit unused during the process. Once this reservoir is full of excess or waste toner, it must be replaced.

The Laser Printing Process

Here is the step-by-step process:

- Sending – data is sent from a PC to the printer, and the printer converts the print command into printer-understandable information.

- Cleaning is another essential part of the process, which involves the physical and electrical removal of the previous print jobs, and preparing the drum unit for the new job.

- Conditioning – this involves applying a static electrical charge to the photosensitive drum and the substrate as it goes through the corona wire. The drum unit gets charged with static electricity in advance, and toner is attracted only to areas exposed to the laser beam (the image imprint), and the electrostatically charged paper attracts the particles when the drum rolls on it and forms the output image.

- Exposing – here, the photosensitive drum is exposed to a beam, which imprints the latent image with a negative charge.

- Developing – in this stage, the charged toner is applied to the latent image formed by the beam on the drum.

- Transferring – the transfer corona wire negatively charges the substrate to attract the positively charged particles before fusing.

- Fusing – the final stage involves the application of heat and pressure in the fuser unit to melt and firmly bond the toner on the substrate. To create the image, the fuser unit melts and presses the toner powder onto the material substrate.

How Do Inkjet Printers Work?

Inkjet printers come in a compact design, use less power, are cheaper, and are remarkably versatile. They work by jetting ink onto print material and drying it naturally. Due to their low cost, they are mainly built for personal use, small office use, and home or school users needing image-heavy documents.

The most common are photo inkjet printers for consumers who need high-resolution photos due to their high-quality color prints.

Overview of Inkjet Technology

The inkjet printers have ink cartridges that are used to hold liquid pigment. Liquid ink combines carbon pigments, drying agents, and other useful components that help it bind to print material.

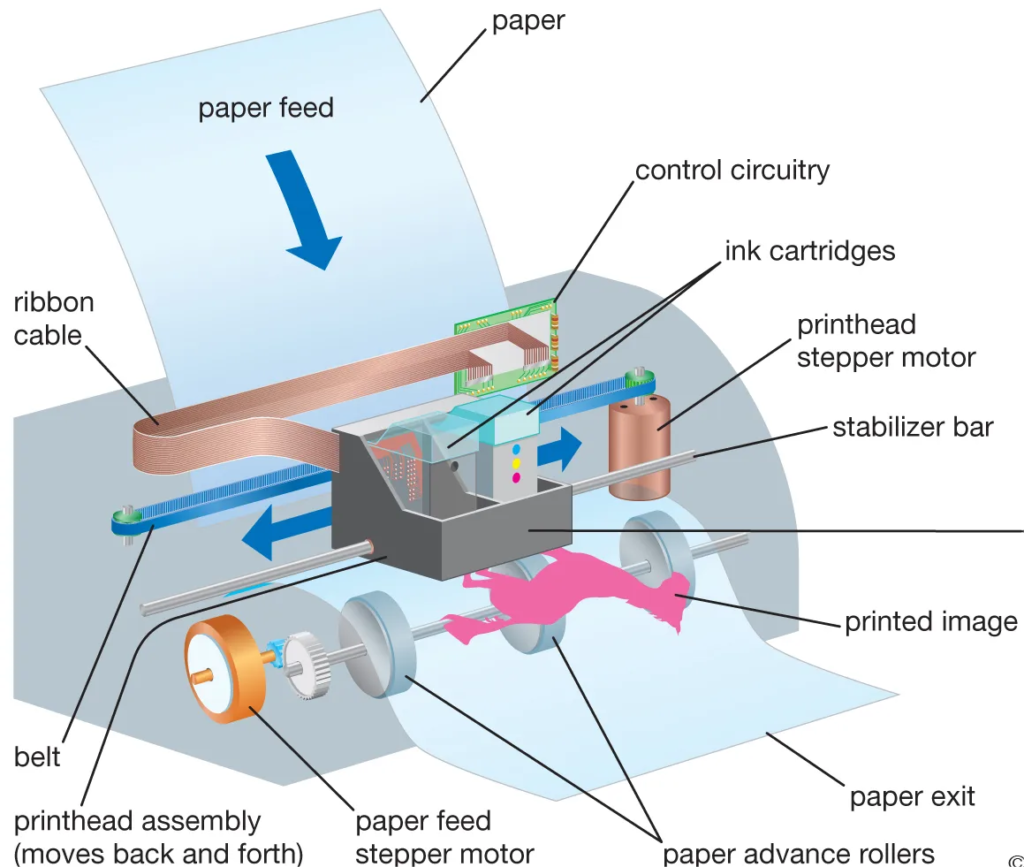

Key Components of an Inkjet Printer

Parts of a modern inkjet printer include:

- The printer usually has a power supply for supplying electrical charge to the machine.

- Interface port(s) – modern inkjet printers have a USB port for connectivity to the PC. But some use a serial port or SCSI port.

- Print head – this is the main part of an inkjet printer. The printhead contains a series of small nozzles for spraying drops of pigment-based ink onto the substrate.

- Ink cartridges come in different combinations depending on the manufacturer and printer model; color and black in a single cartridge, black and color cartridges, or each color with its own cartridge. These cartridges are used to hold the pigment-based ink for the printers.

- Stepper motor – for moving the printhead assembly back and forth across the print substrate.

- Belt – it attaches the printhead assembly to the stepper motor

- Stabilizer bar – for controlling and ensuring the precise movement of the printhead assembly.

- Paper feeder – a tray for loading papers.

- Rollers – for pulling the paper from the feeder and moving it when the printhead is ready for another pass.

- Control circuitry – controlling mechanical operations and decoding information sent from the PC to the printer.

The Inkjet Process

The key principle ink printers use is to convert digital data into physical copies. Every ink printer has a driver that converts digital information into printer language. The converted information is transferred to the printhead. As the printhead moves across the substrate, ink from the cartridges is forced through the tiny nozzles on the printhead in high volumes of individual ink droplets. The printhead uses the information it received, distributes the liquid pigment droplets on the material substrate as it moves across, and creates the intended output in the manner it received the imaging information. With the help of rollers, the printhead creates the entire image on the print paper as it moves through the printer, and once completed, the hard copy is ejected and collected in an output tray. The inkjet printer also excels in producing prints on unusual media like plastic and iron-on transfer sheets without damaging them.

Comparing Laser and Inkjet Printers

A. Print Quality

Inkjet printers have high-resolution color printing than laser printers. Color quality in laser printers is poor with banding. However, laser printers tend to produce black and white copies more than inkjet printers; laser printers are better at producing smaller fonts. With an ink printer, there is the likelihood of smudging while the ink is wet.

B. Speed

Laser printers have higher processing speed than inkjet printers; they can print more pages per minute than their inkjet counterparts. Laser printers have an average speed of 20 pages per minute, while inkjet printers produce six pages per minute.

C. Cost of Ownership

Inkjet printers can be acquired at a significantly lower cost than laser printers. Averagely, the initial investment for a budget inkjet printer is $55, while a laser printer can go for $125. Laser printers cost considerably less per page than inkjet printers, particularly if you want black and white. The cost per page for a laser printer averages 2-5 cents for black and white and 15 cents for color prints, while inkjet printers have an average of 5-10 cents for black and white and 15-25 cents for color prints. The toner cartridge cost is higher than the ink cartridge, but it has a high lifespan, and you will not need toner replacements for some time, even if the machine is not in use. Inkjet cartridges dry up in months even if they it is not in use and needs refilling the cartridge more often; this is one of the cons of an inkjet printer.

D. Suitability for Different Purposes

Inkjet printers are cheap and convenient for personal home or office use due to their high-quality prints. Their low speed makes them suitable for small office and home use.

On the other hand, a laser printer’s speed is high and convenient for professional high-volume needs. Laser printers are, therefore, common in commercial settings.

Environmental Considerations

Energy Consumption

An inkjet printer consumes less energy than a laser printer, making it more reliable from a sustainability perspective printing. Having inkjet technology in place of the laser process significantly saves energy—one of the main reasons inkjet printers continue dominating the industry.

Waste Generation and Recyclability

The latest inkjet printers are more energy efficient, cheaper, and generate less waste. This is crucial for a sustainable business ecosystem. Also, ink cartridge recycling mechanisms and more eco-friendly inks are entering the industry.

Laser printers tend to consume more energy, and their used cartridges are unrecyclable, which poses an environmental threat by excess energy consumption and generating more waste. Ultimately, Epson announced that it would stop producing laser printers by 2026.

Eco-Friendly Features and Certifications

More and more companies, like Packoi, are becoming environmentally aware. They are acquiring printers that consume less energy, generate less heat and waste, and use recyclable papers and eco-friendly inks. Sustainable Green Printing (SGP) Partnership is a leading certification company for print facilities, advocating for best practices to reduce environmental impact and promote social responsibility. Other printer certifications include EcoLogo, Energy Star, and Forest Stewardship Council(FSC).

Tips for Choosing the Right Printer

There are a few considerations when looking for a new printer:

- Print Color or Black and White Both inkjet and laser printers are good for producing color images. However, a monochrome laser printer is an ideal option if you are looking for black-and-white prints only.

- FunctionalityBoth laser and ink printers are essentially good for printing solutions. But the difference between laser and inkjet printers is their functionality and technology. Depending on other factors like budget and your overall needs, you must decide between toner and ink cartridges.

- Price and Other CostsLaser printers are considerably expensive to purchase and operate. The initial cost is over $100, and toner replacements are also expensive. Also, they consume more energy as they require heating and charging of corona wires and drums. On the other hand, inkjet printers can basically go for just over $50, and the ink cartridges are inexpensive. Also, inkjet printers consume less energy than laser printers.

- QualityIf you are looking for high-resolution photo prints, an inkjet printer can be an ideal option, but there could be cases of distortion or smudging when ink is wet. With laser printers, there are no issues of smudging. Both inkjet and laser printers can give you good results, but the laser printer style will surely give better results for all CMYK colors.

- Speed and VolumeLaser printers have higher production speeds than inkjet printers. Also, they can handle high volumes of work while inkjet deal with small volume works.

- SpaceLaser printers are often larger and may require more space. If your space is limited, inkjet printers are good; they come with a compact design to place them on your shelve or desk.

Conclusion

Inkjet and laser printers are the main two printer types in the market. They come with different technologies; the former uses pigment-based ink in cartridges, while the latter uses toner powder to produce prints. These printers have different functionality due to different components and technologies. However, as you look for a printer, various considerations help you understand the differences between laser and inkjet printers, such as business needs, speed, costs, quality, etc. But the most important factor is looking for a printer that will serve your printing needs while causing less environmental harm.

Get Eco-Friendly Packaging Prints with Packoi

At Packoi, we acknowledge the need to be more efficient, eco-friendly, and more socially responsible in our packaging and design solutions. We provide a wide range of packaging designs and printing services. Contact us for high-quality, appealing designs and prints, or click the button below for more information.