Last Updated on November 11, 2025 by Packoi Team

People new to printing often hear about sublimation while exploring ways to personalize products for small shops or gifts. The ink plays a huge part in how long a print lasts and how crisp the colors look on the surface. Good results depend on the correct ink, the right printer, and the right materials.

In this guide, you will see what sublimation ink does, where it works best, and what to look for when starting your first projects. Let’s get right into it.

What Is Sublimation Ink?

Sublimation ink is a specialized ink formulated to sublimate. It is not the same ink you use in your typical office printer. There are two types: aqueous sublimation ink dyes and solvent sublimation ink dyes. It is designed to directly change from a solid to a gaseous state when heated.

The specialized ink is made from dye particles and is specially made for a sublimation printer. The dye particles are suspended in a liquid carrier without dissolving. The complete definition of sublimation inks is based on the sublimation printing process.

How Does Sublimation Printing Work?

The manner in which sublimation inks work is just amazing. This printing method is widely accepted due to its high-resolution images and designs.

Sublimation inks are designed to be used with inkjet printers and are compatible with these special ink cartridges and their inkjet printing technology. The sublimation printer prepares the ink to print on heat transfer paper.

Here’s how the process works:

- Design: A design gets created on design software so you can adjust colors, size, and placement before anything touches a product. Bright colors and high-resolution graphics usually show up best once transferred. Keeping the artwork sized correctly for the blank item saves time later.

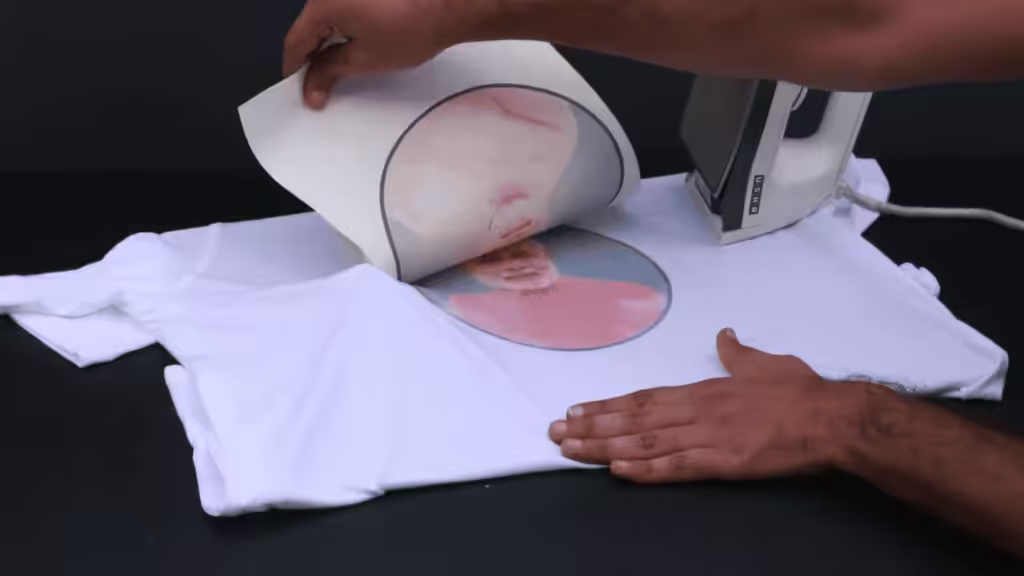

- Print: The printer uses special ink that reacts to heat. The design comes out mirrored because it will flip onto the product during pressing. The sublimation paper holds the ink on the surface long enough to move it onto fabric or a coated object.

- Prepare: The printed sheet goes face down on the item. Heat-resistant tape holds it still, so lines stay sharp. A clean surface matters here. Lint or fingerprints can show through once the color bonds with the fibers or coating.

- Press: The heat press applies a set pressure and temperature, then the ink turns into a gas and sinks into the polyester fibers or polymer coating. No film sits on top. After cooling, the color feels smooth to the touch and can handle washing or daily handling.

This process is common when creating graphic designs on t-shirts. After printing, the ink becomes an integral part of the garment and does not fade over time.

What Do You Need to Start Sublimation Printing?

Getting set up takes a few pieces of equipment made for this type of printing. The combination of the right printer, ink, paper, heat source, and items you print on determines how vibrant and durable the final product will be. Each one plays a role in turning digital artwork into long-lasting color on products.

Here’s what you’ll need:

Sublimation Printer

A dedicated printer is essential. Some printers, like Sawgrass models, come built specifically for sublimation. Others, such as certain Epson EcoTank printers, can be converted to handle sublimation ink.

Regular office printers will not work. Standard ink sits on the surface of a product rather than embedding into it, which means the colors wash away or peel over time. A proper sublimation printer handles the heat-reactive ink consistently, so colors appear bright and true to your design.

Sublimation Ink

The ink used in sublimation printing is unique. It starts as a liquid in cartridges or bottles and turns into a gas when heated. This gas penetrates the fibers of polyester fabric or bonds with polymer coatings on hard goods.

Cheap ink can produce muted or uneven colors, while high-quality options make the difference between a crisp, vibrant print and one that looks dull. Choosing the right ink for your printer type also reduces clogs and ensures smooth operation.

Sublimation Paper

Sublimation paper is more than just a medium to hold your design. Its special coating keeps the ink stable until heat triggers the transfer. This paper also prevents bleeding, which helps edges stay sharp and colors maintain their intensity.

Using regular paper can result in faded prints or smudging because it doesn’t release the ink evenly. Different papers are available for specific printer types and project sizes, so picking the right one helps you get predictable results.

Heat Press

Heat and pressure are what move the ink from paper to product. Flat heat presses work well for t-shirts, tote bags, mouse pads, and other flat surfaces. Mug presses wrap the design evenly around cylindrical items, while convection ovens suit tumblers and curved blanks.

Each machine must maintain consistent temperature and pressure for a precise time. Even slight variations can affect how deeply the ink bonds, altering durability and color vibrancy.

Sublimation Blanks

The items you print on need to accept the sublimation ink. Polyester fabric allows the dye to embed directly into fibers. Hard goods, like mugs, keychains, or phone cases, require a polymer coating.

Without this, the ink cannot adhere, and the design will peel or wash away. Beginners often start with t-shirts or coffee mugs because these items are widely available and forgiving for practice. Expanding to puzzles, coasters, and metal items comes after learning the basics.

What Can You Make with Sublimation?

Sublimation inks come with a wide range of applications. The increasing reliability issues of screen printing have led to the use of sublimation printing technology because of its high-quality prints. With their unlimited advantages, sublimation printers have found their way into some key industries.

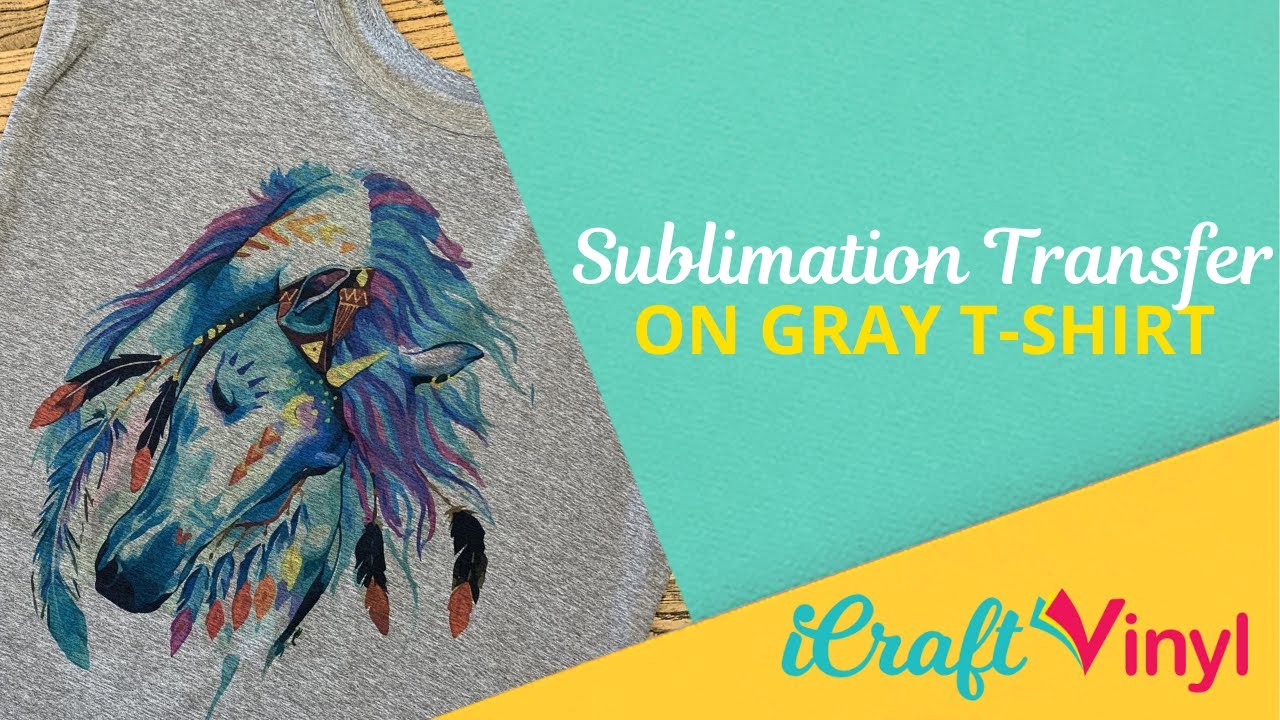

Apparel & Textiles

Think of a vibrant image printed in full color across a t-shirt. Sublimation works especially well on textiles like polyester garments, as well as apparel such as t-shirts, jumpers, and socks. All polyester fabrics can take sublimation ink, allowing the colors to sink into the fibers rather than sit on top.

Garments printed with this method are durable. The designs do not wear off or fade after repeated washing. The ink becomes part of the fabric itself, so the print has no added texture or “feel.”

This makes it ideal for clothing that looks bright and clean while staying comfortable to wear. Sublimation ensures that every item retains its color and detail over time, from everyday t-shirts to specialty sportswear or socks.

“Hard Goods” & Promotional Items

The demand for custom prints on personal items is high. Dye sublimation printing allows the creation of desirable images and other prints on hardware items.

You can sublimate on any item that has a special polymer coating. This includes:

- Ceramic Mugs & Tumblers

- Phone Cases

- Plates

- Mousepads

- Keychains

- Metal Panels

Some people also want to create personalized images on the surface of items like mugs and plates. The sublimation printing method can produce vivid designs on hardware items that can maintain vibrant colors even after washing.

Is Sublimation Printing Worth It? (Pros vs. Cons)

Deciding whether to invest in the right printer, ink, and materials requires a clear look at the good and the bad. Here are the pros and cons of sublimation printing:

The Advantages (Pros)

Sublimation printing is a process in which ink is transferred from a printed piece onto a substrate, creating a permanent bond that won’t wash off or fade with time. Sublimation printing uses a special type of ink called sublimation ink. Here are some pros of printing with sublimation inks:

1. High-Quality, Vibrant Images

Sublimation printers produce high-quality, sleek results. The sublimation ink reaches the printing material in gaseous form. It penetrates and firmly binds to the fabrics under controlled heat and pressure. The dye particles of the ink are embedded in the substrate and cannot fade easily.

The sublimation process gives more detailed prints and high-resolution printing results. Unlike screen printing, where smudging and smearing pose a risk to image quality, sublimation printing is not affected by such factors.

2. Extreme Durability

Sublimation prints have proven to be durable. Heat presses under pressure on the prepared heat transfer paper ensure the sublimation ink forms a firm image on the printing surface, including rigid surfaces of items like mugs and plates.

The vivid image does not peel or scratch off and is close to permanent on the printed material, which is not the case with DTG printing.

For example, sublimation printing on garments can last longer without fading until the item is worn out. The sublimation inks are designed to be waterproof and resistant to UV, scratching, or abrasion over time.

3. Versatility

One of the key advantages of sublimation printing is its flexibility with materials. The sublimation inks can print on a wide range of substrates, barring pure cotton or silk. You can use sublimation inks to print on polyester fabrics, wood, glass, cardboard, and metal surfaces.

Even the cotton, if treated with a polyester layer, can be sublimated with specialized ink. Business owners take advantage of sublimation printing since it can print on a wide range of materials.

4. No “Hand” or Feel

The level of customization in sublimation printing is higher compared to other printing methods. It allows people to create near-permanent images and other graphics rather than adding layers on top of their items. It is ideal for quick customization and printing of personalized, intricate designs on mugs, apparel, and other items.

In today’s fashion markets, it is challenging to find garments without graphic designs; people are seeking clothing that is both attractive and made from the right fabric.

Even plain t-shirts or other garments on the market are sold without preprinted designs to allow customers to apply their desired graphics. The intricate designs will not peel as long as the print is applied effectively to the surface.

The Disadvantages (Cons)

While there are many advantages to printing with sublimation inks, there are also some cons to consider:

1. High Initial Setup Cost

The initial cost involved in setting up sublimation printing is high. The cost of a sublimation printer is higher than that of a standard inkjet printer.

In fact, special printers and inks are more costly than other printing methods. This is because the sublimation printer requires a special heat press machine, which increases the cost. This printing method is not cost-effective, especially when dealing with large quantities.

2. Does NOT Work on Cotton

Dye sublimation printers can only work with plastic substrates, especially polyester. All the printing materials must be coated with a layer of plastic polymer before printing. Dye-sublimation inks are not ideal for natural fabrics like cotton unless they are coated with a polyester layer before printing.

Materials polymer-coated with plastic polymers pose a risk to the environment. These materials produce solid waste, hindering sustainability efforts made by customers and businesses.

3. Only Works on Light-Colored Materials

The processes involved in sublimation printing are complex. From setting up the printing machines and preparing the transfer paper to heat pressing and producing a printed output, sublimation printing must be laborious.

Heat-pressing each item individually and printing individual transfer papers makes the process tedious and complex. The repetition of these processes for individual items can also make sublimation printing slow.

4. Process Can Be Slow

The specialized inks in a sublimation printer cannot print on dark surfaces. Because the sublimation inks are transparent or sometimes translucent, they are only usable with white backgrounds and bright-colored objects. This incompatibility is a great downside for the application of sublimation printing.

FAQs

Q1: What is sublimation ink used for?

Sublimation ink is used in heat transfer printing to create permanent, full-color designs on polyester fabrics or polymer-coated items. The ink turns into gas under heat, embedding into the material for durable, vivid prints.

Q2: Can I use sublimation ink on cotton?

No. Sublimation ink only bonds with polyester fibers or polymer-coated surfaces. Natural fabrics like cotton or silk will not hold the colors.

Q3: Will sublimation prints fade or peel over time?

Prints made with sublimation ink are extremely durable. The ink becomes part of the fabric or coating, so designs resist peeling, cracking, and fading, even after repeated washing or long-term use.

Q4: Is sublimation printing environmentally friendly?

While sublimation produces minimal waste, it mainly works with polymer-coated materials, which may not be fully sustainable unless responsibly sourced.

Q5: What materials work best for sublimation printing?

Sublimation printing works best on polyester fabrics and polymer-coated products like mugs, keychains, and tumblers.

Conclusion

Sublimation printing presents a suitable digital technology for vibrant-colored and high-quality designs. The sublimation inks come with excellent features that, upon printing, become a permanent part of the printed material. Also, the sublimation printer uses special technology to produce the desired quality output.

However, the sublimation ink comes with specific advantages and disadvantages that are crucial to getting started with sublimation printing. While getting started with your sublimation printing business, it is important to keep in mind your environmental goals.

Create Durable, Full-Color Prints with Packoi

Are you looking for packaging designs and printing solutions? Well, Packoi is a trusted company dealing with packaging designs and printing services. We have helped business people stand out from the competition with custom packaging designs and printing with our leading technologies.

Get your custom designs and printing today! Contact us or visit Packoi for more information.