Last Updated on September 22, 2025 by Packoi Team

Printing is essential to many businesses because it helps make packaging, advertising materials, and promotional items. As a result, choosing the right printing method is crucial to achieving the desired outcome for your project. Two common printing methods are offset printing and silk screen printing.

Both have pros and cons, and choosing the best option for your project depends on your needs. In this post, we’ll define offset and full printing techniques vs. silk screen printing, highlight their advantages and disadvantages, and provide guidance on choosing between the two print methods.

Offset Printing

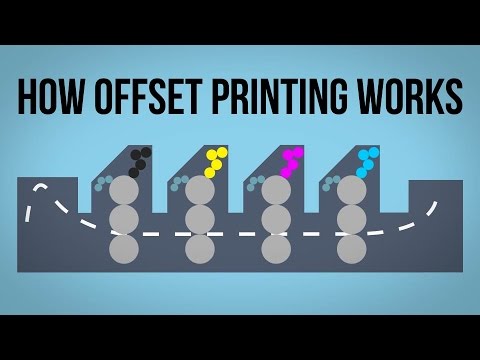

Offset printing is a traditional printing technique that involves an inkjet printer transferring an image or design onto a rubber blanket, which, in turn, transfers the ink onto paper.

The reason why it is called “offset printing” is that the ink is not transferred directly from the screen printing to the paper, but is transferred to the rubber blanket and then transferred to the paper.

How Does it Work?

Offset printing works by using plates with the digital image or design to be printed. The plates are made of metal or plastic and have a specific area for printing the image or design. The ink is applied to one plate, and then the plates are pressed onto a rubber blanket, and the liquid ink is then transferred to the paper.

Advantages of Offset Printing

This traditional method remains a top choice for commercial projects due to several key advantages:

- Cost-effective for large quantities: Offset printing is ideal for printing large quantities of the same inks and the same design since it requires a one-time setup cost, no production time, and the cost per unit decreases as the order quantity increases.

- High-quality digital printing: Offset digital printing produces high-quality digital printing with sharp and clean images suitable for printing fine details and small text.

- Versatile: Offset printing can be used on various paper types and sizes, including glossy, matte, and textured paper.

While these benefits make it a powerful tool, it’s not the perfect solution for every project.

Disadvantages of Offset Printing

Generally, it’s crucial to weigh its drawbacks before committing to this method for your project.

1. Setup Time and Cost

Offset printing is a popular printing method used for various applications, from books and magazines to marketing materials and packaging. While it offers many advantages, this printing method also has its share of disadvantages that should be considered before deciding whether it is the right print option for your printing needs.

One of the main disadvantages of offset printing is the setup time and cost. The printing process often requires a longer setup time than other printing, as the plates must be created and mounted on the press.

This can take several hours, which can add to the overall turnaround time of the project. Additionally, for garment printing, the setup cost can be high, as it includes the cost of creating the printing plates and the setup of the press. This cost can be spread over many units, making offset printing more cost-effective for large orders.

2. Limited Color Options

Another disadvantage of offset printing is the limited color options. Offset printing is limited to CMYK colors (cyan, magenta, yellow, white, and black), which can result in less vibrant colors than other printing methods. It cannot produce metallic or fluorescent colors, which can be a limitation for designs that require these colors.

If your design requires specific ink colors or metallics, you may need to consider another printing method, such as digital printing.

3. Not Ideal for Small Orders

Offset printing is also not ideal for small orders. As the setup cost can be high, offset printing may not be cost-effective for printing small units. The cost per unit for the offset process may be high, making it more expensive than other printing methods, such as digital printing or silk screening.

If you only print at a small number of shops and need a small number of units printed, you may need to consider other printing to keep costs down.

Silk Screen Printing

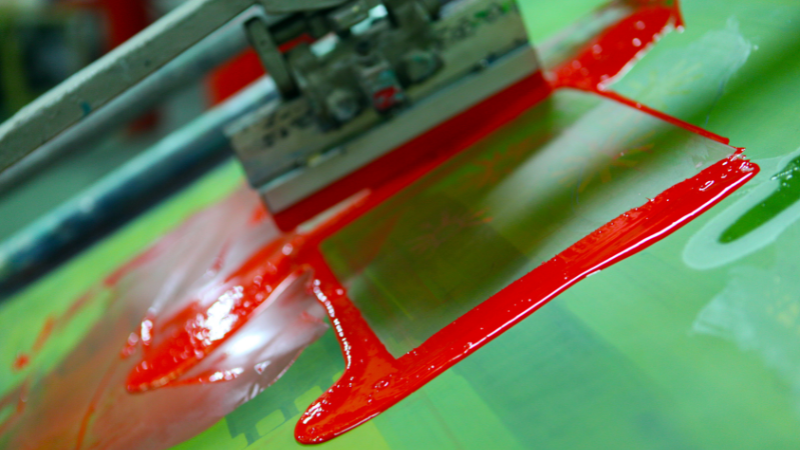

Silk screen printing is a printing technique that involves pressing ink through a stencil onto the surface to be printed. The stencil is made of a fine mesh material stretched over a frame, with the desired design or image cut out of the mesh.

How Does the Silk Screen Work?

Silk-screening involves creating a stencil on a fine mesh screen. The screen is then placed over the material to be printed, and ink is applied to the top of the screen. A squeegee is used to press the ink through the stencil onto the material. The two ink stencils block the ink in the areas where the printed design or image is not desired.

Advantages of Silk Screen Printing

This versatile technique offers a unique set of benefits, making it ideal for a wide range of custom projects:

1. Highly Cost-Effective for Small Orders

Silk screening printers are ideal for small orders since the setup cost, unlike screen printing, is relatively low, and the cost per printer unit remains constant, regardless of the number of units printed.

2. More Color Options, Prints, and Design Possibilities

Silk screen printing can produce prints in a wide range of colors, including metallic and fluorescent colors, and can print on a variety of materials, including fabric, glass, metal plates, and plastic.

3. Ability to Print on a Variety of Surfaces

Silk screen printing can print on a variety of surfaces, including curved and irregular surfaces, making it ideal for printing companies and business names for promotional business items such as water bottles, t-shirts, pens, and other promotional business products.

3. Disadvantages of Silk Screen Printing

Despite its flexibility, it’s important to be aware of the potential limitations of this method:

1. Time-Consuming

Silk screen printing can be a time-consuming process since each color in the design requires a separate stencil, and each color must be applied separately. This can lead to longer lead times for completing a project, especially if the design has multiple colors.

Each color must be applied and allowed to dry, and then the next color can be applied directly. The process can be time-consuming, but it is necessary to ensure that each color is applied correctly and that the final product meets the desired quality standards.

2. Low-Resolution

Silk screen printing has a lower resolution than other printing methods, making it less suitable for printing fine details, inks, and small text. The ink used in silk screening is thicker than the ink used in specialty inks and other printing, which can lead to less precise and defined edges in the final image and printed product.

This can result in a less detailed and less professional-looking final printed product. While Silk screen printing can produce vibrant and bold colors, it may not be the best option for designs that require intricate details.

3. Quantity

When deciding between offset, digital printing, and Silk screen printing, it’s essential to consider the specific needs of your project. Quantity is critical since both offset and digital printing are more cost-effective for larger quantities, while silk screening is more cost-effective for smaller quantities.

If your design requires metallic or fluorescent colors, Silk screen printing may be better since offset and digital printing are limited to CMYK colors.

Silk screen printing is more versatile when it comes to design possibilities since it can print on a variety of materials and can produce a wide range of colors. However, if your design requires fine details or small text, offset printing may be better since it has a higher resolution than silk screening.

4. Surface

The surface is another important factor to consider since silk screens can print on various surfaces, including curved or irregular surfaces. This makes it a great option for printing on items such as bottles or promotional items.

In contrast, offset or digital printing is limited to flat surfaces, and digital printing may not be the best option for curved or irregular surfaces.

Make a Decision Based on Your Specific Needs

The best printing method is the one that fits your project’s specific goals. To find the right fit, evaluate your project against these four key criteria.

| Choose Offset Printing If... | Choose Silk Screen Printing If... |

|---|---|

| You need 500 or more identical items. | You need a small, custom run of items. |

| Your design is photographic or highly detailed. | Your design is bold, graphic, and uses spot colors. |

| You are printing on paper, cardboard, or corrugated boxes. | You are printing on fabric, glass, plastic, or curved surfaces. |

| You need precise CMYK color reproduction. | You need vibrant Pantone colors or specialty inks (e.g., metallic). |

1. Order Quantity

Your order size is the most critical factor. Choose offset printing for large quantities (500+), as the high setup cost is offset by a very low per-unit price. For small, custom runs, choose silk screen printing due to its low setup costs, making it the most economical choice for limited quantities.

2. Design Complexity

The detail in your artwork is a key differentiator. Choose offset printing for high-resolution designs with fine details, small text, or photographic images. For bold, graphic designs with solid colors, the vibrant and durable finish of silk screen printing is the superior choice.

3. Printing Material (Substrate)

Consider the surface you are printing on. Choose offset printing exclusively for paper and paperboard products like boxes and commercial mailers. For virtually any other surface—including fabric, glass, plastic, or curved items—the unmatched versatility of silk screen printing is required.

4. Color Requirements

Your color needs will guide your decision. Choose offset printing for designs requiring precise, full-color (CMYK) reproduction. For projects that need exceptionally vibrant, opaque spot colors (Pantone/PMS) or specialty inks like metallics, silk screen printing is the better option.

Ultimately, the decision between offset printing and Silkscreen printing comes down to your specific needs. Consider the quantity, colors, design, resolution, and surface when deciding which traditional screen printing method to use.

FAQs

Q1. What is offset printing best used for?

Offset printing is ideal for high-volume projects requiring sharp details and consistent quality.

Q2. Is silk screen printing more durable than offset printing?

Yes, silk screen printing produces long-lasting prints, especially on promotional items and textiles.

Q3. Between offset printing and screen printing, which method between offset printing and screen printing is cheaper for small orders?

Silk screen printing is usually more cost-effective for small quantities.

Q4. Can offset printing produce metallic or fluorescent colors?

No, offset printing is limited to CMYK colors, while silk screen printing allows metallic and fluorescent inks.

Q5. Between offset printing and screen printing, which printing method gives higher resolution?

Offset printing provides sharper details and higher resolution compared to silk screen printing.

Conclusion

Offset printing and silk screen printing are two common printing methods with their own advantages and disadvantages. Choosing between the two print methods depends on your specific needs, including quantity, colors, design, resolution, and surface. Consulting with a printing professional can help you make the right choice for your project.

Get Design Services from Packoi Now!

If you need design services for your printing project, Packoi can help. Our team of experienced designers can help you create a design that meets your specific needs. Contact us and visit our website to learn more about our design services.