Last Updated on May 21, 2025 by Packoi Team

Ever wondered why blister packaging is the go-to choice for so many products, from medications to electronics? This versatile packaging method isn’t just about aesthetics; it plays a crucial role in protection and consumer safety.

In this blog post, we’ll dive deep into blister packaging and everything you need to know about blister packaging to optimize your packaging strategy. Whether you’re a startup or an established company, understanding the ins and outs of blister packaging could be the key to enhancing your product’s appeal.

What Is Blister Packaging?

Blister packaging is a popular option you’ve likely encountered numerous times daily. Blister packaging involves sealing a product in a pre-formed plastic pocket, or “blister,” typically backed by a sturdy material like cardboard, paperboard, or aluminum foil.

This type of packaging is most commonly seen in the pharmaceutical industry, where pills, tablets, and capsules are packaged securely to ensure they are protected from contamination, moisture, and other external factors.

The “blister” part of blister packaging is made by heating a plastic sheet until it’s malleable and then forming it around a mold to create a pocket form that perfectly fits the product.

Once the product is placed into these pockets, the backing material is securely sealed up against the contours of the blister form, often through a heat-sealing process. This sealing method protects the items’ integrity and makes the package tamper-evident, making any unauthorized access easily noticeable.

What Type of Plastic Is Blister Packaging Normally Made of?

When it comes to blister packs and packaging, the choice of plastic material is crucial for the physical protection of the product inside and its environmental impact. Let’s explore the most common plastics used in product blister packs and packaging and their environmental friendliness.

1. PVC (Polyvinyl Chloride)

PVC is one of the most prevalent materials used in blister packaging due to its durability and clarity, which are essential for the retail display of products. However, PVC is not environmentally friendly. During its manufacture and disposal, PVC releases dioxins and other chlorinated pollutants, which harm the environment and human health.

These substances can contribute to respiratory issues, cancer, and reproductive problems in wildlife. Recycling PVC is also challenging due to the heavy metals and phthalates often added for flexibility, further compounding its environmental impact.

2. PET (Polyethylene Terephthalate)

PET is favored for its strength and transparency and is commonly recycled, making it a more sustainable option than PVC. PET can be recycled into many products, including fiber for polyester fabric and new PET containers and packaging, reducing the need for virgin materials and the energy consumption associated with production.

While PET recycling is widespread, it is not a perfect solution; the process of recycling PET can still consume considerable energy and produce waste.

3. RPET (Recycled Polyethylene Terephthalate)

RPET is made from recycled PET materials, such as water bottles and containers, making it a more sustainable choice. RPET reduces landfill waste and uses less energy to produce than virgin PET.

However, the quality of RPET can vary depending on the recycling process and the source materials, which can limit its application in some types of blister packaging.

4. PLA (Polylactic Acid)

Produced from sustainable materials such as sugarcane or cornstarch, PLA is a biodegradable plastic. It is one of the most environmentally friendly options for blister packaging, as it produces significantly lower greenhouse gas emissions during production than conventional plastics.

PLA is compostable under industrial composting conditions, breaking down into carbon dioxide, water, and organic materials, which means it does not contribute to landfill mass. However, PLA’s biodegradation process requires specific conditions that are not widely available in many municipal compost facilities.

5 Types of Blister Packaging

Blister packaging varies widely to suit different materials and product requirements, ranging from essential visibility to enhanced protection. Here, we’ll delve into the common types of blister packaging and their characteristics.

1. Face Seal Blister Packaging

Face Seal Blister packaging is the most basic form, featuring a pre-formed plastic blister pack typically made from PVC or PET, adhered to a cardboard backing only at the plastic blister pack’s edges.

This type feels rigid and clear, offering straightforward visibility and cost-effectiveness, making it popular in retail for items such as toys, electronics, and tools.

However, the environmental impact is significant, especially with PVC, which emits toxic chemicals during production and is challenging to recycle.

2. Full-Face Seal Blister Packaging

Full-Face Seal Blister extends the coverage of the plastic to the entire front and edges of the cardboard, enhancing the protection and durability of the packaging.

Like the face seal blisters, they are made from PVC or PET but provide additional security for the contents, commonly used for pharmaceuticals and cosmetics. PET variants are preferable for their recyclability and lower environmental footprint.

3. Full Card Blister

Full Card Blister covers the entire cardboard backing with plastic, which is mechanically secured rather than heat-sealed. This type usually comprises thicker and more robust PVC or PET, suitable for heavier or more valuable items needing substantial protection.

The thicker plastic increases material use but offers excellent security, and if PET is used, it remains recyclable.

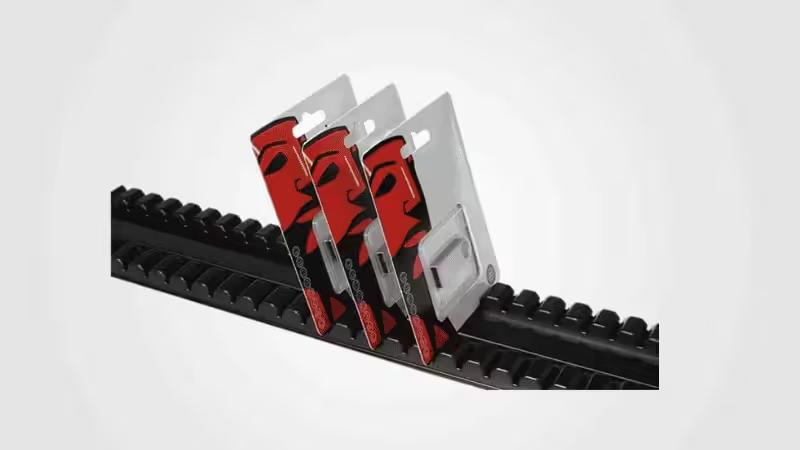

4. Trapped Blister Packaging

Trapped Blister packaging features a plastic blister pack sandwiched between two pieces of cardboard without heat-sealing the plastic directly to the card. This structure uses thinner, more flexible plastic, often PVC or PET, providing a sleek presentation for products like electronics or stationery.

The additional cardboard reduces the amount of plastic used, slightly mitigating the environmental impact, mainly when PET is the coating material employed.

5. Clamshell Packaging

Clamshell packaging comprises a single or two-piece hinged plastic case that snaps or seals shut, providing robust protection and often reusable features. Made from durable plastics like PET, clamshells are ideal for high-value items or products requiring a secure, reusable package, such as electronic gadgets or food products.

Despite its practical benefits, full clamshell packaging often has a high environmental impact due to its complex structure and the difficulty of recycling the mixed materials. However, designs focusing on single-material use, particularly PET, can enhance recyclability.

Advantages and Disadvantages of Blister Packaging

Blister packaging is popular in many industries. However, like any packaging option, it has its strengths and weaknesses. Below, we’ll examine the advantages and disadvantages of blister packaging.

Advantages of Blister Packaging

- Blister packs provide a high level of protection against environmental factors that can degrade products.

- The blister packaging design shows if the product has been tampered with, enhancing consumer trust and safety.

- Packages are designed for ease of use, allowing consumers to access one product at a time while keeping the remainder sealed and secure.

- The clear plastic component allows consumers to view the product without opening the packaging, aiding decision-making and reducing the need for open-package displays.

- Despite the initial setup costs, blister packaging can be economical for mass production. The materials are inexpensive, and the packaging process can be highly automated.

- Particularly beneficial for pharmaceuticals, blister packaging allows for precise control of dosage amounts.

Disadvantages of Blister Packaging

- Not suitable for all product types, particularly those too large or oddly shaped for the standard blister pack formats.

- Depending on the materials used (often PVC), blister packaging can be less environmentally friendly due to challenges with recycling and the production process that may emit harmful chemicals.

- Creating custom molds for blister packaging can be significant, but it might be prohibitive for small businesses or those with frequently changing product lines.

- While effective in protecting products, blister packaging can generate more waste than other options due to the combination of plastic and cardboard components, which are not always recyclable.

- The very feature that adds security, the tamper-evident design, can sometimes make blister packs challenging to open, leading to “wrap rage” among consumers.

What Products Do Blister Packs Suit?

Blister packs and packaging aren’t just a packaging choice; they are strategic decisions that enhance product integrity. Let’s dive into which products benefit most from using blister packaging machines and packs:

1. Pharmaceuticals

Blister packs are most commonly used in pharmaceutical industries. They are ideal for pharmaceuticals because they offer precise dosage control and maintain the integrity of medications by protecting them from moisture, light, and contamination. This packaging material is also child-resistant and tamper-evident, critical for safety in pharmaceutical applications.

2. Consumer Electronics

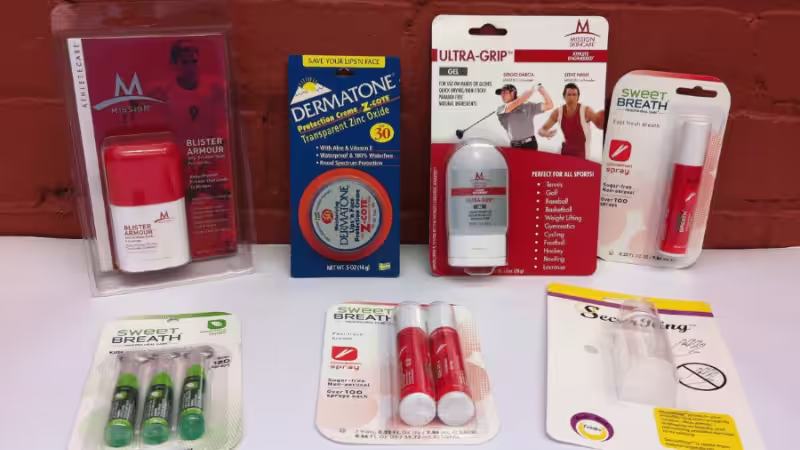

Blister packaging protects sensitive components from static and physical damage to consumer electronics while allowing clear visibility. This is crucial for consumer trust as buyers can verify the product’s condition and authenticity without opening the blister packaging machine.

3. Cosmetics and Personal Care Products

In cosmetics and other forms of personal care, blister packs help maintain the hygiene and quality of products such as makeup brushes, mascara wands, and small bottles. The secure packaging sealed blister packs prevent contamination and extend the product’s shelf life.

4. Tools and Hardware

Blister packaging is extensively used for tools and hardware because it securely encases sharp and heavy items, preventing movement and damage during transport. The clear plastic allows customers to see the product entirely, which is essential for items like drill bits, nails, and screws.

5. Toys and Games

For toys and games, blister packs are not only protective but also visually appealing. They provide a clear view of the product, which can enhance its display appeal and help catch the attention of younger audiences.

6. Food and Snacks

Blister packs in food and snacks are less common but are used for portion control and preservation of freshness. This type of packaging is often seen in the confectionery sector for items like chewing gum or mints.

7. Hardware and DIY Products

DIY enthusiasts appreciate blister packs as they make it easier to see what they are buying and verify the package contents without opening it. This same form of packaging is handy for assortments of small, easily lost items like washers, nuts, and bolts.

8. Pet Products

Blister packs are used in the pet industry primarily for small, packaged, consumable items such as treats and medications. The packaging ensures that these products remain fresh and free from contaminants.

Key Factors to Consider When Designing Blister Packaging

Designing blister packaging machines requires careful consideration to balance functionality with aesthetic appeal. Here are the key factors to remember to ensure your blister packaging machine meets consumer expectations and manufacturing requirements.

1. Product Compatibility

The material chosen for blister packaging must be compatible with the product to avoid chemical reactions or contamination. For instance, foods and pharmaceuticals often require barrier properties that protect against moisture and oxygen, making materials like high-barrier plastics essential for blister packing.

2. Visibility and Display

Blister packaging should enhance product visibility to attract customers. Clear, high-quality plastic allows consumers to view the product without opening the package, which is crucial for retail sales, where the first impression can significantly influence buying decisions.

3. Protection and Security

The primary purpose of blister packaging is to protect the contents from environmental factors and handling during shipping and retail display. Additionally, packaging should be tamper-proof and evident, providing visible proof that unauthorized access has occurred, which is especially important for pharmaceuticals and high-value consumer goods.

4. Sustainability

Environmental considerations are increasingly critical in packaging design. Opting for recyclable materials like PET or biodegradable options such as PLA can help reduce the ecological footprint of your packaging. Designing for sustainability also includes considering the product’s entire lifecycle to minimize waste.

5. Cost-Effectiveness

Cost-effective materials and production processes should align with the budget without compromising quality. Efficient design can reduce material use and streamline manufacturing processes, lowering production costs.

6. Consumer Convenience

Ease of use is a significant factor in consumer satisfaction. Blister packaging should be easy to open when intended but secure enough to protect its contents. Features like perforations or easy-peel corners can enhance user experience without sacrificing security.

7. Regulatory Compliance

Especially crucial in industries like pharmaceuticals and food, packaging must comply with relevant regulations and safety standards. This includes using FDA-approved materials and ensuring the packaging does not contaminate or degrade the product.

Frequently Asked Questions about Blister Packaging

Briefly introduce the purpose of the FAQ section, which is to address common questions and concerns about blister packaging.

1. What is the purpose of blister packaging?

Blister packaging protects products from external factors such as humidity, water vapor contamination, and UV rays for extended periods. This packaging method is beneficial for preserving the integrity and longevity of products by shielding them from environmental damage.

2. What is the future of blister packaging?

The future of blister packaging looks promising, with the global healthcare blister packaging equipment market projected to reach USD 32.46 billion by 2030, growing at a CAGR of 7.8% from 2024 to 2030.

3. What are the common problems with blister packaging?

Common issues with the blister packaging process include adhesive build-up, thermal expansion, and clean-up challenges.

4. What is the blister process in the pharmaceutical industry?

In the pharmaceutical industry, the blister and sealing process involves creating a sealed protective cavity from materials like aluminum foil or plastic to safeguard products against moisture, heat, oxygen, and contamination.

5. What medication cannot go in a blister pack?

Certain medications are unsuitable for blister packs and packaging, including inhalers, eye drops, and any medicine that requires on-demand use. These items need alternative packaging solutions to ensure proper handling and effectiveness.

Conclusion

Blister packaging safeguards your products and enhances their market appeal through superior visibility and protection. By selecting the ideal blister packaging for your items, you can boost consumer trust and compliance with industry standards, ensuring your products stand out in a competitive marketplace.

Selecting the proper blister packaging for your brand involves balancing functionality with aesthetic appeal to represent your brand’s values and meet consumer expectations.

Find Your Ideal Blister Packaging Solution with Packoi

If you’re looking for expert advice on blister packaging options, Packoi is here to assist. We offer tailor-made blister pack solutions that cater to specific needs, ensuring your products are secure and attractive.

Contact us today to discuss your blister packaging requirements. We’re ready to give you a detailed quote and help you make an informed decision that aligns with your business objectives.