Last Updated on January 16, 2025 by Packoi Team

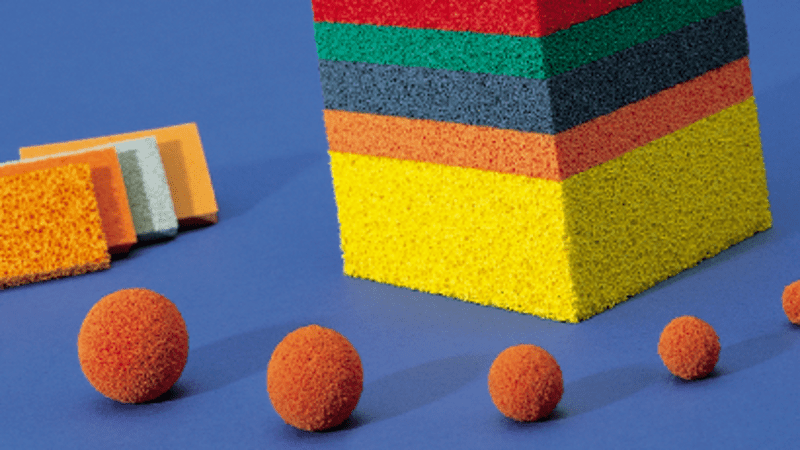

Since there are several insert materials (including sponge rubber, foam rubber, shredded paper, Eva foam, etc.), it is necessary to look at different ways of choosing the best option to meet your packaging and unboxing expectations.

Gift boxes are necessary packages usually customized to give an aesthetic presentation to customers. Similarly, insert options need to embrace the beautiful presentation of the gift boxes to present the product(s) more attractively.

Selecting the best insert option or material will secure your product in a gift box and give your customer a fantastic unboxing experience. So, to choose the best insert option, we will look at guiding tips to ensure you choose the suitable gift box insert to meet your needs.

What Is Eva Foam?

Eva foam is a soft, rubber-like, and durable ethylene-vinyl acetate polymer. It is a popular insert material in the market today thanks to its exceptional qualities and usability.

EVA foam has a lower density than foam and sponge rubber, which are known to be heavier, denser, and more durable. This makes it more suitable for use when there is a risk of physical damage in packaging.

Materials of EVA foam take a closed-cell form structure. EVA is an ethylene copolymer, and vinyl acetate is created through hot molding and blowing. The vinyl acetate percentage ranges from 10 to 40, with the remaining percentage being ethylene plastic. The amount of vinyl acetate determines the character of Eva produced.

A suitable cushioning and effective EVA will usually have a higher quality of vinyl acetate than a brittle, hard, and cardboard-like EVA. EVA pellets are added to a mold, and a blowing agent is added while mixing.

As the mold is heated, the agent breaks down into a gas. This gas is trapped in the liquid polymers (molten EVA pellets), expanding and forming tiny bubbles. That is how we ended up with Eva foam insert materials.

Common Applications of Eva Foam

EVA foam has more applications and uses than one can imagine. It has several uses as the most common cushioning material against physical impact. These include, but are not limited to, the following:

- Because of its soft and lightweight make, it is a key material in the extensive production of goods like backpacks, hats, shoe soles, shoes, ergonomic seats, and sandals, among other products.

- EVA foam is also waterproof, lightweight, and UV resistant. This makes it suitable for making floatation belts, swimming kickboards, and toys.

- It is biocompatible and resistant to chemical damage, making it a suitable material for use in the medical sector.

- Puzzle mats made of EVA foam are popular in home flooring, home gyms, and studios.

- Also, EVA foam is a versatile material in packaging, commonly used as an insert material to cushion products against physical damage.

What Is Foam Rubber?

Perhaps the term “foam rubber” confuses many since foam and rubber are two different things. You can create foam rubber from natural rubber, synthetic rubber, or chloroprene with chemical or gaseous blowing agents to create small bubbles in a liquid mixture of water, polyols, polyisocyanates, colorants, and fillers.

It is a cellular rubber that has been treated with a blowing agent in a foaming process to form a firm, spongy foam material.

Common Applications of Foam Rubber

Some of the common uses of foam rubber include:

- Foam rubber makes shock absorbers thanks to its soft, spongy, and printhead-closed surface structure.

- Another common application of foam rubber is manufacturing vibration isolators and sound insulation materials in studios.

- Due to its spongy foam and flexibility, foam rubber is a good material for making seats, mattresses, and carpet stoppers.

- Because it has bubbles enclosed in its structure, foam rubber is suitable for protection against damage. Therefore, it is a good fill material for packaging to secure products against damage.

What Is Sponge Rubber?

Sponge rubber manufacturing is similar to foam rubber, except that sponge rubber is made into two different densities: open and closed.

In closed-cell sponge rubber, the surface is closed, and holes within the material are not interconnected. The closed-cell sponge rubber has balloon-like cells holding nitrogen gas from chemical powder added during heating and compression, forming dense closed-cell materials.

With open-cell sponge rubber, the surface has many open holes since sodium bicarbonate is added to the heated mold, the uncured sponge rises, and baking soda creates open, interconnected cells. This enhances air circulation within the material. This makes it a lightweight material with more air.

Common Applications of Sponge Rubber

- Closed-cell sponge rubber is fabricated to offer shock absorption, especially in cars. Unlike rigid foam rubbers, flexible foams are softer and compress-resistant, making them suitable for shock absorption in car seats.

- Open-cell sponge rubber has elastomeric components that allow water and gases to pass. This makes it a suitable material for making medical sponges, medical filters, and sterilization bags, among others.

The Differences between Eva, Foam, and Sponge

- EVA is formed from ethylene plastic and vinyl acetate, while foam and sponge rubber is formed from natural rubber, synthetic rubber, or chloroprene.

- EVA and foam rubber come in only one form of closed cell density, but sponge rubber comes in two different densities of open and closed cells.

- EVA form is less dense than foam and sponge rubber.

How to Choose the Right Insert Option for Gift Box?

Packaging fills, or inserts are important in product packaging and shipping. There are several insert options you can choose for packaging supplies. But how do you choose the right insert material or option for your gift box? Well, here are some guiding tips:

- Size and Weight of gift box: For weighty products and larger gift boxes, ensure you use insert materials that will hinder your product from moving side to side, cushioning it against the box’s walls. Tough, compressible, and flexible fill material will serve its purpose.

- The fragility of the products: Fragile items must be handled with great care. Otherwise, your supplies might not reach the customer. In handling highly fragile items, you need to insert materials that cushion items from shock and physical impact while at the same time holding the items securely within the box. This will protect the items against shocks in unfavorable shipping environments.

- The required shock absorption level: It is related to the kind of product and its fragility. Ensure you choose a fill material depending on the protection you need for your items against various shocks.

To test the effectiveness of the chosen insert options, you can do the following:

- Perform drop tests: After you package and fill the void spaces with your chosen fill material, you can perform drop tests to ascertain if the option is effective and if items will remain intact without damage.

- Inertness tests: Ensure the insert materials you choose are chemically inert and do not produce anything that may harm your items.

Conclusion

Packaging inserts are great for filling the void spaces around your items in a package. The inserts help to secure your product’s contents and protect them against shocks or physical damage. However, we have seen several insert options: EVA, sponge rubber materials, and form rubber.

Therefore, for you to get the best insert for your supplies, we have compiled some guiding tips to help you succeed in your packaging and product shipping. You can also learn more about different product packaging inserts from our website.

Get Perfect Packaging Solutions for Your Business with Packoi

Packoi is a leading company in packaging solutions. They help businesses with customized packaging materials, including gift boxes. We are a click away from aesthetically presentable, quality gift box designs with sturdy materials. Visit us Packoi or contact us here for more details.