Last Updated on November 11, 2025 by Packoi Team

Box sleeve packaging offers a smart and stylish way to upgrade your product presentation without a full redesign. From simple belly bands to custom die-cut sleeves, there is a sleeve design for every product.

In this article, we’ll explore popular box sleeve styles, highlight their benefits, and share design tips to make your packaging stand out.

What is a Box Sleeve?

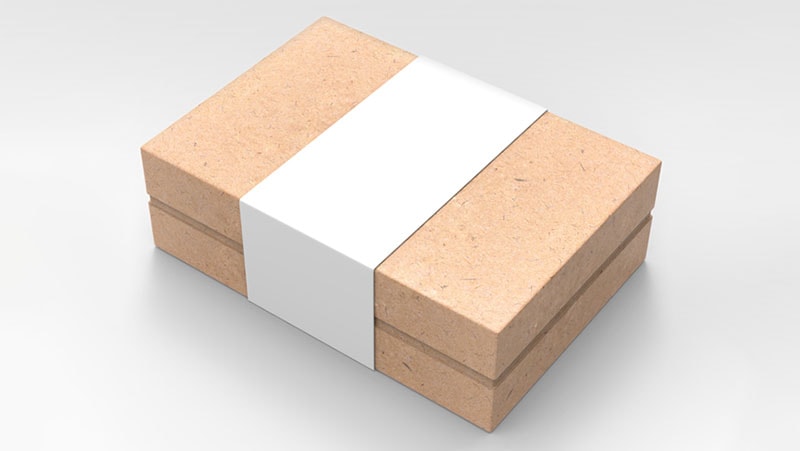

A box sleeve or sliding box is a packaging cover that wraps around your existing packaging box. It’s a cost-effective and unique way to customize your packaging design without breaking the bank.

Sleeves that cover the entire packaging are called sleeve boxes. Because they have the appearance of an outer box. Partially covering sleeves are called belly bands, as they only cover the midsection of the product packaging.

Its biggest benefit is the ability to customize a generic packaging design. Take a standard brown cardboard box and add a custom design box sleeve on top. Some sleeve boxes are used as a protective layer, keeping luxury packaging safe during shipping.

Most packaging sleeves are made from a thin cardboard sheet that is glued into a square tube-like design. However, you can also find packaging sleeves made of paper, plastic sheets, hard cardboard, and even fabric.

8 Types of Box Packaging Sleeves

Standard box sleeves are only one small part of the greater packaging sleeve design. Sleeves are a flexible way to add branding to an otherwise bland product design. Here is a table of the most popular packaging sleeves.

| Sleeve Type | Cost | Application | Key Benefit | Drawback |

|---|---|---|---|---|

| Plain Sleeve Boxes | Low to Medium | Standard Boxes Packaging | Affordable, Easy to Print & Good Customization | Limited Protection |

| Half Sleeve Boxes | Very Low | Promotional or Budget Packaging | Cost-Efficient, Minimal Material Use & Versatile | Less Branding Space |

| Die-Cut Sleeve Boxes | Medium to High | Unique Product Packaging | Stand Out Design Compatible with Irregular Items | Higher Production Cost |

| Tray & Sleeve Boxes | High | Premium Product Packaging | Strong Box Structure with Elegant Unboxing | Expensive and Long Lead Times |

| Window Cut-Sleeves | Medium | Product Display Packaging | Product Visibility & Stylish Design | Higher Assembly Cost |

| Flexible Sleeves | Low | Food Containers & Irregular Boxes | Fits Various Shapes and is Tamper-Evident | Less Durable |

| Adhesive Sleeves | Very Low | Packaging Bottles & Cans | Easy Branding, Fits Various Shapes, and is Tamper-Evident | Non-Removable |

| Peel & Seal Sleeves | Low | Flexible Wraps for Irregular Containers | Convenient Packaging & Sealing | Limited Applications |

Now, let’s dive into the types of box packaging sleeves to decide which one fits your product

1. Plain Printed Sleeve Boxes

Box sleeves are made from thin cardstock with custom designs printed on the outside. This is your standard box sleeve design. These sleeves are printed as flat rectangles and later joined at the edges to form a square tube.

The rectangular sleeve design is easier to print and cut than complex, full-printed boxes. All of these result in a significantly lower price per unit. Box sleeves are the most effective way to add branding, company logos, artwork, and colors to your packaging.

You can customize box sleeves to your heart’s content. Popular finishes include matte textured paper, gloss printed cardboard, and embossed text. Many brands produce limited edition packaging sleeves for electronics with unique artwork and colors.

2. Half Sleeve Boxes (Belly Bands)

Half box sleeves are smaller bands that generally cover the center (belly) of the packaging box. Hence, they are commonly called belly bands. This packaging design further increases the cost-efficiency of box sleeves. Now you require less material to cover your boxes.

Regular sleeve boxes have one goal: to fully cover the base packaging with an attractive cover. However, half sleeves serve several functions.

- Works as a cost-effective packaging sleeve.

- It can be used as a tamper-evident seal on a box.

- Useful for promoting discounts & bundles.

- Sleeves for containers with irregular shapes and sizes.

When used correctly, the belly band can elevate normal-looking packaging to a premium status.

3. Die Cut Packaging Sleeves

Some packaging sleeves use a non-rectangular design. These packaging sleeves have irregular edge designs, and some have cutouts in the middle to facilitate the base packaging. Naturally, these changes make die-cut packaging sleeves more expensive.

Die-cut sleeves have custom dimensions that require specialized cutting tools. These are used for covering non-standard packaging, like jars, bottles, trays, and bundled items. Some brands also use it to differentiate themselves from the competition.

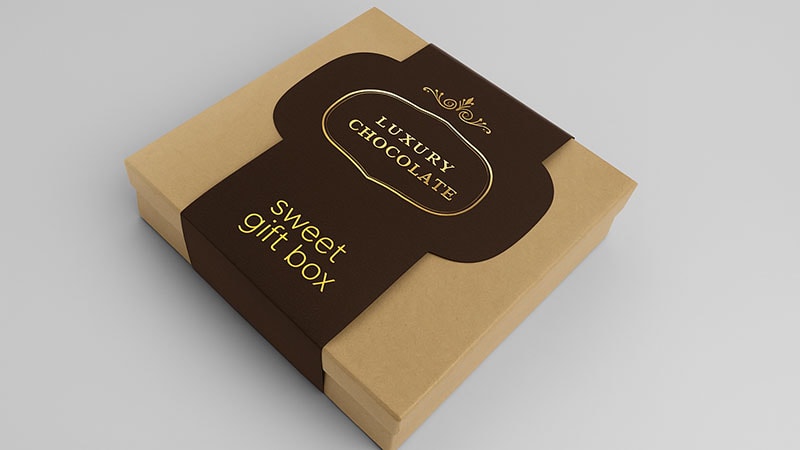

4. Tray and Sleeve Boxes

Tray and sleeve boxes combine the base packaging with a box sleeve design for a drawer-like packaging design. An open cardboard box acts as the container for your products, and the sleeve acts like a cover.

The most common example of a tray and sleeve box design is the humble slide-out matchbox. However, many brands employ tray and sleeve boxes to ensure a premium unboxing experience for the customer. Usually, a cloth tab is added to the tray to make the design more ergonomic.

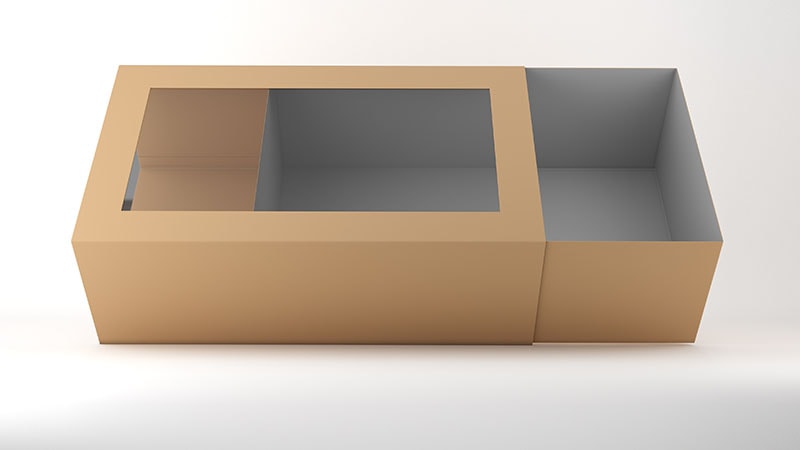

5. Window Cut-Out Sleeve Boxes

Window cut-out sleeves are a combination of die-cut and tray sleeves. It uses a tray base and a sleeve with a die-cut hole in the middle that acts as a window. Optionally, you can use a clear plastic layer for better protection.

If belly bands are the most versatile sleeve option, windowed sleeves come in a close second. They give customers a preview of the packaging content without the need to unbox.

Windowed packaging boxes are a popular option for food items like chocolates and pastries. The garment industry also creatively uses window sleeves for product previews. This custom packaging is often used for bundles of ties, underwear, scarves, etc. So, customers can check the fabric material before making a purchase.

As far as custom sleeve boxes are concerned, you can never go wrong with a window design.

6. Flexible Packaging Sleeves

Regular sleeve boxes are made from cardstock, which has a rigid structure. They will only fit square boxes of a certain size. However, you can also get sleeves made from plastic or paper, which are more flexible.

These sleeves are generally used for clear food containers like salad boxes. Salad boxes come in varying sizes, and the bottom is usually smaller than the top, which has a lid. So, a flexible sleeve enables easy custom packaging and creates a tamper-evident security seal.

7. Adhesive Sleeves

As the name suggests, these flexible sleeves are attached to the product packaging using adhesives (glue). The most common example of adhesive packaging sleeve design is the water and soda bottles.

Printing on clear PET bottles is expensive and hinders their recycling. So a thin, flexible style sleeve showcasing brand image and product nutritional details is the easiest way to customize the packaging.

Unlike other packaging sleeve designs, this is a non-removable sleeve. While you can use adhesive sleeves to make custom boxes, their best application is branding bottles.

8. Peel and Seal Sleeves

Peel and seal refers to a specific type of packaging mechanism that uses an adhesive strip design. A narrow or wide double-sided tape is applied to the opening, with the other side left untouched.

When the company packages its product, it can remove the protective film from the tape and seal the package shut. Peel and seal sleeves aren’t glued to the package. The double-sided tape connects the overlaps where the two sides of the packaging paper meet.

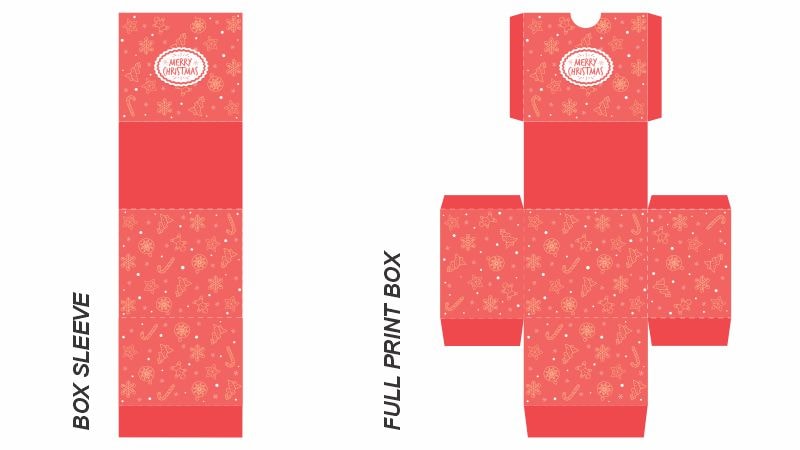

Box Sleeves vs. Full Printed Boxes: Comparison

The traditional way to customize a product packaging is by getting a fully printed box. Although this is an effective marketing and branding method, it can be costly.

- Inefficient Printing: Custom-printed box designs require more print area. Additionally, the asymmetric box designs result in a lot of material waste.

- Durability requirements: Packaging boxes are made from thick or corrugated cardboard. Printing on thicker materials is more expensive.

On the other hand, sleeve packaging boxes are way more practical. They use a flat rectangular design, making them incredibly print-efficient. Since packaging sleeves are a secondary packaging element, they can be as thin as you desire.

Here is a comparison table that highlights the main differences between packaging sleeves and custom printed boxes.

| Features | Custom Sleeve Boxes | Full Print Boxes |

|---|---|---|

| Design | Wraps around the container box | Box container for products |

| Branding Impact | Conveys Simplicity | Conveys Luxury |

| Production Time | Short | Long |

| Customization | Limited | Extensive |

| Requirements | Needs a Base Packaging | None |

| Material Use | Minimal | High |

| Storage Size | Compact | Bulky |

| Eco-Friendliness | High | Moderate |

| Best Application | Seasonal & Promotional Packaging | New Products & Luxury Goods |

| Cost | Low | High |

Both solutions have their unique advantages and thus serve very different applications. Let’s dive into it to understand which packaging option delivers the best value for your business and marketing objectives.

Packaging Sleeves

Packaging sleeves are best suited for low-volume promotional or seasonal packaging. Small businesses can take advantage of sleeve boxes and get professional printing for a lower price.

Applications:

- Promotional/Seasonal Packaging

- Budget Branding Option

- Creative Packaging Ideas

- Flexible Packaging for Containers

Custom Printed Boxes

Custom-printed boxes are great for large quantity orders. You can get custom dimensions, materials, thickness, and varnish finish. It’s a great way to establish your brand identity and gain customer attention.

Applications:

- Large Volume Packaging

- Luxury Packaging

- Product Segmentation

- New Product Launch

It should be noted that low-cost full box designs often skimp on materials and protective coatings to hit a low price point. So in many cases, a well-designed packaging sleeve can feel more premium than a poorly planned custom packaging.

3 Reasons to Choose Box Sleeves over Custom Packaging

Box sleeves are an incredibly efficient branding and packaging tool. Here are three reasons why box sleeves are a better option for your business.

1. Versatile Packaging

Boxes are limited. Not all products are suited to a traditional box shape. Heavy products need thicker cardboard, liquids need leakproof glass/plastic, and budget items need something more cost-effective.

Packaging sleeves accomplish all this and more. You can adapt a sleeve design to almost every type of product.

2. Flexible Procurement Options

Complex packaging designs have a minimum order quantity (MOQ). Meaning you have to order tens of thousands of packages to make the order profitable for the manufacturer. While this is not a problem for big corporations, small businesses can’t meet such strict criteria.

It also prevents businesses from trying out new packaging ideas. Sleeves lower the barrier for effective and impactful packaging, giving business owners more control over their brand.

3. Cost Effectiveness

Box designs are expensive. The cost of materials, printing, and assembly is much higher than that of simple packaging sleeves. Packaging mistakes are also harder to resolve when dealing with full print boxes.

A good branding practice is to use generic boxes for durability and sleeves for customization. After your business grows and sales increase, you can switch to fully custom-printed packaging.

5 Packaging Sleeve Design Tips for Impactful Branding

Branding is important for every business, and packaging sleeves can help you boost your brand identity.

Here are five important tips to help you design your custom boxes and packaging sleeves.

1. Product Requirements

Always choose packaging sleeves that match your product design. Here are some examples:

- Luxury products: premium packaging sleeves

- Fresh products: see-through packaging sleeves

- Eco-friendly products: paper-based packaging sleeves

2. Colors & Visibility

Create sleeve designs that balance colors with visibility and readability. Your product name, company logos, descriptive text, and artwork details should stand out from the background.

Use the color wheel to determine the best combination of colors for your graphics and artwork. You can also explore and download templates from online resources and start from there.

Several custom packaging manufacturers offer free design support and assist in realizing your branding vision.

3. Minimal or Bold Design

Don’t overdo the designs. Luxury packaging sleeves focus on materials and quality over colors and designs. Sometimes, the minimalist packaging sleeves leave a bigger impact on the customers.

For health-focused products, you want to maximize your print real estate. Detailed information on nutrition, calories, and sugar quantity is a mark of reliability in the health industry.

4. Advertise Your Services

Use that packaging sleeve space to advertise your brand and service. Let consumers know about your other products, doorstep delivery options, free coupons, sustainability initiatives, and more.

A product’s sleeves need to be a complete package. It needs to have style, colors, logos, important information, and contact details.

5. File Formats

Before proceeding with the print, make sure your file formats match industry standards. Images (PNG, JPG) and PDFs are universal, but they reduce the design details.

Design formats like PSD, TIFF, EPS, and AI retain the original design details and result in sharper and more vibrant packaging sleeves. Confirm the recommended file format and correct size from the printing company before you upload your design.

FAQs

Q1: What is the standard size of a box sleeve?

There is no standard box sleeve size. Sleeve size depends on your packaging box size.

Q2: Are box sleeves eco-friendly?

Yes, box sleeves are incredibly eco-friendly. They use less material and ink than full box prints.

Q3: Can I print custom designs on both sides of a box sleeve?

Yes, but there is no benefit to printing on the inside as it isn’t seen by the customer.

Q4: What’s the difference between a sleeve and a belly band?

A sleeve covers the entire packaging box, whereas a belly band covers a small area in the middle.

Q5: How much do custom box sleeves cost compared to full boxes?

Price varies based on print quality and finish. Box sleeves generally cost less than half the price of a full box.

Conclusion

Selecting the right box sleeve for your product is no easy task. The right combination of primary packaging and sleeve design can make or break a brand. We recommend that small businesses start with sleeves and slowly move up to full custom boxes. Remember, an effective packaging strategy is more valuable than premium materials.

Get Custom Boxes & Sleeves from Packoi!

Packoi is a leading manufacturer and supplier of custom packaging and print materials. We specialize in high-quality product boxes, gift bags, and packaging sleeves. All our products are 100% customizable with flexible MOQ options.

We also offer in-house packaging design services and technical support. For quotes and queries, contact us now!