Last Updated on November 24, 2023 by Packoi Team

Shipping boxes are one of the staples of any business. It’s an important shipping boxes material that helps companies deliver products or receive supplies.

The question is, do you need to create your own boxes for shipping?

The truth is that some shipping companies, like UPS and FedEx, provide free shipping boxes. These are already included in the shipping costs.

But there are times when it’s more prudent to create your own. This is especially true if you do a lot of shipping.

If you think you need to have your own boxes for shipping, read on.

In this article, you’ll learn the basics of shipping box materials and how you can choose the right ones for your business.

4 Different Types of Shipping Boxes

It is beneficial to have your own shipping box. You can design your shipping boxes to your heart’s content and put your brand on them so they can double as free advertising.

You can also choose the right materials that won’t leave you with cheap shipping boxes. You get to pick high-quality materials that can protect your product throughout the delivery process.

But before we go deep into the materials that you can use, let’s understand the 4 common types of shipping boxes that businesses use nowadays.

1. Standard Corrugated

Most of the shipping boxes that you’ll see are single-wall corrugated boxes. Corrugated paper material is composed of 3 sheets (medium) and 2 liner boards. A medium is a paperboard that’s shaped in waves, and it’s glued in the middle of the liner boards.

Single-wall corrugated boxes have 2 liners and 1 medium. This is the standard for shipping boxes. It’s not too heavy but it’s still quite durable. The corrugated material gives it enough strength and sturdiness to withstand the rigors of shipments and deliveries. It’s strong enough to carry 40 lbs of items.

2. Double-Walled

This is the thicker version of the standard corrugated boxes. Think of it as having 2 mediums and 3 liner boards. This makes the corrugated cardboard box stronger and able to carry heavier items without breaking.

Admittedly, double wall boxes will cost you more than the standard shipping boxes. But if it can guarantee that your items will reach their destination in one piece, then it should be worth it.

There’s even a thicker version – the triple-walled box. It has 3 mediums and 4 liner boards. This is considered to be just as strong as wooden boxes – but lighter.

3. Multi-Depth

This is a type of corrugated box that can be adjusted in height. It starts tall but there are grooves that allow you to lower the box so it fits the contents better.

This will ensure that your cardboard boxes won’t take up a lot of space during shipping. The less space is occupied, the lower shipping costs will be incurred.

Choose this style if you always ship items in different quantities. The multi-depth allows you to order boxes in bulk.

4. Bulk Cargo

This is considered the biggest option for shipping boxes. These are ideal for sending wholesale orders – whether they involve multiple smaller boxes or extra-large contents.

These cardboard boxes use double-walled corrugated material. This is due to the quantity that this type of box carries. They need stronger material so the box won’t break under the weight of the contents.

With heavier loads, there may be times when a triple-walled corrugated material is needed.

6 Shipping Materials for Your Outer Packaging

The most crucial part of shipping boxes is the material of the outer packaging. Don’t settle for cheap shipping boxes that might compromise the items that you’re shipping out. Invest in good quality materials to ensure that it’s robust enough to withstand the rigors of a typical delivery journey.

Before you choose shipping supplies like the tape and fillers for the inner packaging, you have to choose the right outer packaging first. This will determine the durability and sturdiness of your box.

Here are the options that you can consider.

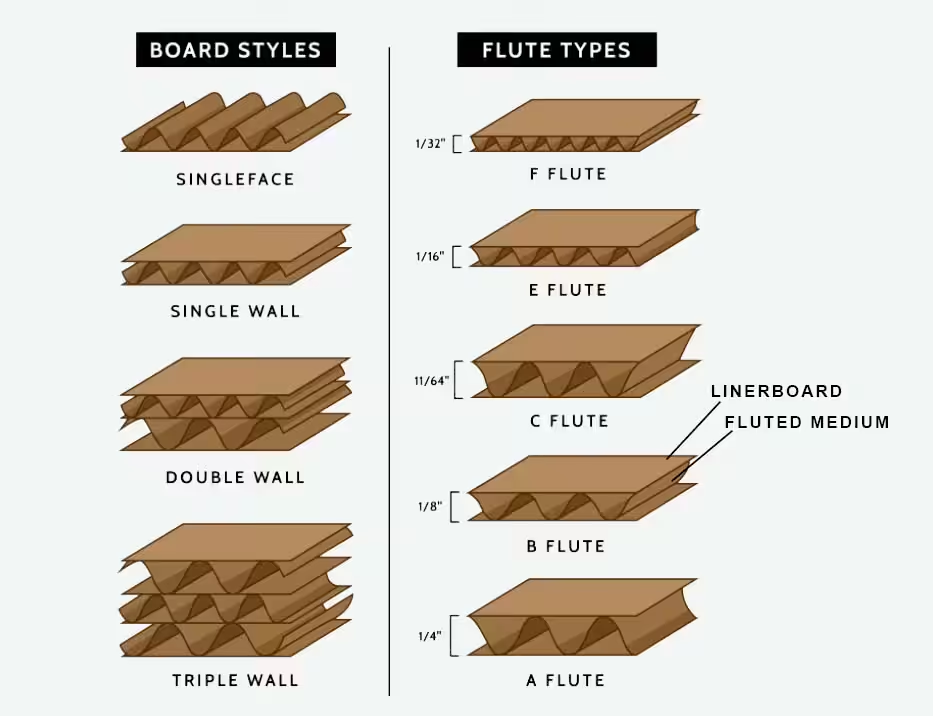

1. Corrugated Cardboard Fluted

This is the most common material used for shipping boxes. Corrugated cardboard has the fluted material for the medium. This gives the box thickness and durability.

If you want to use a corrugated box for your shipments, you need to choose the flute profile of the box. The greater the flute is, the higher the overall strength and stacking ability.

There are 5 types of flute profiles.

- Flute A – 1/4” high. This is the thickest of the flute options. It’s the best packaging material for packaging fragile items. Cardboard boxes with this type of flute profile have the greatest stacking, compression, and cushioning abilities.

- Flute B – 1/8” high. This is ideal for padding and has puncture-resistant features. The thickness of this cardboard is good for printing.

- Flute C – 11/64” high. This is ideal for shipping boxes meant to carry heavy items. It has superb resistance to compression and can withstand crushing weight. This is commonly used as the medium for corrugated boxes.

- Flute E – 1/16” high. This is the ideal profile for retail and display packaging – specifically for those that require printed designs.

- Flute F – 1/32” high. This is the thinnest of the flute profiles. It’s used for shoeboxes and similar packaging. Since the flute is thinner, the cardboard ends up being stiffer.

2. Corrugated Box Layers

This type of material measures the layers of mediums and liner boards used to complete the corrugated cardboard boxes.

To recap, the medium is the fluted cardboard material. The liner boards are flat boards that are glued to either side of the medium.

There are 4 types.

- Single-face board. This is composed of 1 medium and 1 liner board attached to one side. This is the thinnest of the box layers and is usually reserved as packaging filler.

- Single-wall board. This is composed of 1 medium that’s sandwiched between 2 liner boards.

- Double-wall board. This is composed of 1 single wall and 1 single-face board attached together.

- Triple-wall board. This is composed of a double wall and 1 single-face board attached together. As mentioned, this corrugated material is the strongest of the shipping boxes – even as strong as lumber.

3. Waxed Cardboard

There are corrugated shipping boxes that are coated with wax. This allows the cardboard boxes to be stored in refrigerated containers without damaging the paper-based material.

The wax effectively protects the material from the moisture that comes from melting ice.

This type of cardboard material is ideal for food and other perishable items like raw meat, seafood, or chicken.

4. Anti-Static Corrugated

This type of outer packaging helps manage the effects of static electricity that the box might go through. Products like electronic devices may be damaged if they’re not protected from this.

To avoid this, corrugated cardboard boxes are treated with an anti-static coating. There are two ways to do this.

One is to treat shipping boxes with anti-static chemicals and the other is through anti-static sheets. These are organic compounds so spraying them on untreated cardboard materials is safe.

5. Poly Boxes

These shipping boxes are made of polyethylene film. Compared to cardboard materials, these are more durable and reusable. These can also be customizable and cheap.

What’s great about poly boxes is they have a built-in resistance to water. They also have extra padding to keep the contents protected from damage.

5. Insulated Shipping Boxes

Insulated boxes are most suitable as food shipping boxes.

These are boxes that combine the features of cardboard and styrofoam materials. Insulated shipping boxes are specially designed containers used for transporting temperature-sensitive products. These boxes typically incorporate materials that provide thermal insulation, ensuring that the contents maintain a stable temperature during transit.

Insulated Shipping Boxes are designed to protect perishable items such as food, pharmaceuticals, and certain chemicals from temperature fluctuations that can occur during transit.Insulated shipping boxes are indispensable in the cold chain logistics industry, the insulation in these boxes can vary in type, ranging from foam inserts to reflective materials or specialized coolants like gel packs or dry ice.

Their ability to keep products at a consistent temperature, coupled with their robust structure and customizable options, makes them an essential choice for businesses and individuals looking to ensure the safe and effective delivery of temperature-sensitive goods.

6 Inner Packaging and Cushioning Materials

After finalizing the outer packaging of the shipping boxes, you can focus on the other packing materials that protect the items or products being delivered.

There are several shipping supplies that you can use to ensure that the items you’ll ship will reach their destination in one piece.

Here are some of your options for the inner packaging and cushioning material.

1. Paper

Paper is a cushioning material that adds aesthetic appeal to the inside of the box. Among your options include crumpled paper, tissue paper, or confetti.

Admittedly, it’s not the best at providing maximum cushion so it’s not advisable for fragile items.

But if you choose the right colors and paper material, it can create a positive unboxing experience for the recipient of the box.

2. Shredded Corrugated Cardboard

This is a great material to cushion items inside shipping boxes. These shipping materials are recycled corrugated cardboard boxes.

If you have old shipping boxes that are damaged or torn, get them through a shredder or cut them manually. It may be time-consuming but this is an option that’s both environment-friendly and cost-efficient.

3. Bubble Wrap

This is a plastic sheet filled with bubbles – or pockets filled with air. The air inside each bubble makes it an ideal cushioning material for shipping boxes.

Bubble wrap is lightweight and quite effective in shipping fragile items and keeping safe. Even if boxes are jostled and bumped into each other, the items inside are protected.

What’s great about bubble wrap is it can protect items with irregular shapes. It can easily wrap around items so every part won’t have scruffs and scratches.

If you’re concerned about being environmentally friendly, there are bubble wrap alternatives made of bio-plastic. These are more sustainable options that you can use.

4. Air Pillows

This is just like bubble wrap in the sense that they both use plastic and air to cushion items in shipping boxes. But the difference is air pillows look like small pillows. The pillows can be attached to each other or as individual pillows.

These are flexible enough to be put around the items to keep them from the sides of the box. It can also be positioned on top of the item so it won’t be damaged even if boxes are stacked on top of it.

Like bubble wrap, there are bio-based alternatives that are more eco-friendly than plastic air pillows.

5. Packing Peanuts

If you want every space in the shipping boxes to be filled with cushions, your best option is packing peanuts. These are usually made of styrofoam which is deemed a hazard to the environment.

Fortunately, there are eco-friendly alternatives that are made of starch. These packing peanuts can dissolve in water – so they can easily be disposed of without increasing packaging waste.

6. Foam Sheets Or Rolls

Shipping boxes can also use foam sheets or rolls to protect contents from breaking. These are lightweight and effective enough for fragile items.

Most of these sheets and rolls are made of styrofoam. While there’s no specific news about eco-friendly alternatives to these two, there is a biodegradable foam introduced in the market. It can be an option if you want to be sustainable with your shipping supplies.

7 Tips When Choosing the Shipping Box Materials

Now that you have an idea when it comes to the packaging supplies and materials for your shipping boxes, it’s time for you to make your choice.

But don’t be too quick to choose cheap packing materials. You’ll end up with low-quality and cheap shipping boxes that could leave you with damaged goods.

If you want to choose the right materials, here are tips that you can use.

1. Consider Your Products

Your packing materials for shipping should primarily keep your products safe. So if you’re deciding on the thickness, size, and cushioning materials, make sure it’s what your items need.

If you have a fragile item, don’t settle for tissue paper or shredded corrugated cardboard. You might need something that can protect it more – like bubble wrap or foam sheets. They’re more expensive but they can provide what your product needs.

2. Understand the Labels

There are standard labels that are required by shipping companies and regulating authorities. You want to ensure that your corrugated cardboard boxes comply with these labels.

This will guide you in terms of the strength and thickness of the materials that you’ll choose for your shipping boxes.

3. Check with Shipping Companies

If you need proper guidance, it’s always best to go straight to the shipping companies for information. Visit their websites and see their standards when it comes to shipping services and their boxes.

You should also look at their free shipping boxes. These companies even offer free shipping supplies. This is ideal for companies that don’t ship items often.

Of course, these free shipping boxes carry the brand of the shipping companies. If you want your own brand on the box, you might have to create custom boxes.

4. Think of the Journey

When choosing the right packaging materials, it’s also important to look at the journey that the shipping box will go through. If it will go through several logistics hubs, then you need to take that into account. Make sure the box is sturdy enough to survive the trip.

This will also give you an idea about the shipping costs that you have to shoulder. You can balance that with the cost of the materials that you’ll use to create your shipping box.

5. Don’t Forget about Storage

In most cases, corrugated cardboard boxes are ordered in bulk. What will you do with the boxes that you’re not using?

Think about how your storage can protect every shipping box that’s waiting to be used. Make sure the materials can be stored flat so as not to take up a lot of space.

6. Make It Sustainable

To create eco-friendly shipping boxes, you have to ensure that all your packing materials are eco-friendly. From the cardboard to the lamination, coating, cushioning materials, tapes, labels, and ink – all these have to be environmentally friendly.

Just one element that’s toxic will waste your efforts to be sustainable.

7. Get From the Right Sources

Order your boxes from the right sources. Don’t just get cheap shipping boxes from any company. Make sure they’re reputable packaging companies that source their raw materials responsibly.

Look for certifications and see the feedback that past customers have about them. This will give you hints if the company is worth partnering with.

Are You Looking for a Shipping Box Supplier? Packoi Printing Can Provide Sustainable Packaging for Shipments.

Shipping boxes are a vital part of any business. It may seem like a trivial thing to worry about. But it does deserve your attention if you want to protect the items and products that you’re shipping.

To ensure that your shipping boxes are made of high-quality materials, partner with the right packaging supplier.

Packoi Printing has years of experience in producing and delivering sustainable shipping boxes. We have samples and options for you to choose from.

Give us a call with your packaging requirements and we’ll get back to you with a fair quotation in no time.