When ordering custom boxes, getting your dimensions right is the single most important step. A mistake of just half an inch can be the difference between a perfect fit and a box that is unusable, leading to damaged products or wasted money. But how do you read those strings of numbers?

This guide will walk you through the industry standard for reading box dimensions (L x W x H), teach you how to measure correctly, and explain the critical difference between internal and external measurements.

Internal vs. External Dimensions

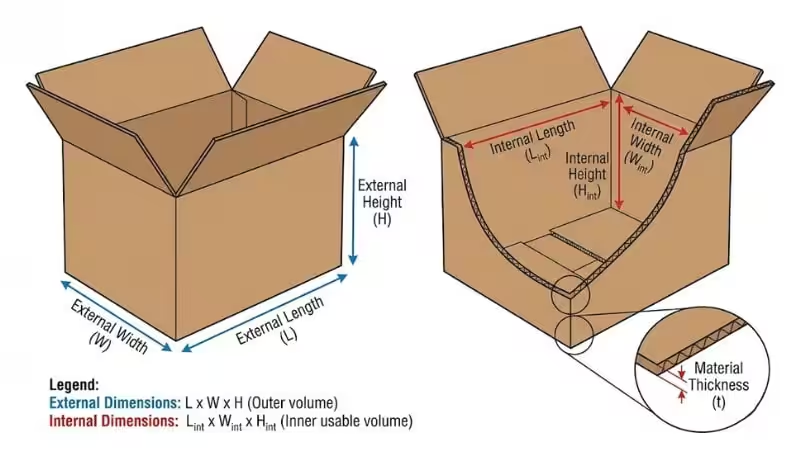

Before you pick up a tape measure, you must understand why you are measuring. In the packaging industry, there are two distinct sets of dimensions, and confusing them is the most common mistake beginners make.

1. Internal Dimensions (ID)

These are the measurements of the inside of the box. The purpose of it is to ensure your product fits.

When you are ordering custom boxes from a manufacturer like Packoi, you will almost always provide the Internal Dimensions. This guarantees that the usable space inside the box is sufficient for your product.

2. External Dimensions (OD)

These are the measurements of the outside of the box, including the thickness of the cardboard material. This is for shipping and logistics.

External Dimensions are critical because Corrugated cardboard has thickness (flute). A standard shipping box might have walls that are 1/8″ to 1/4″ thick. If you order a box based on external dimensions, the internal space will be smaller by that amount, and your product might not fit!

Your shipping carrier (like UPS, FedEx, or DHL) and your warehouse will use these dimensions to calculate shipping costs and plan pallet stacking.

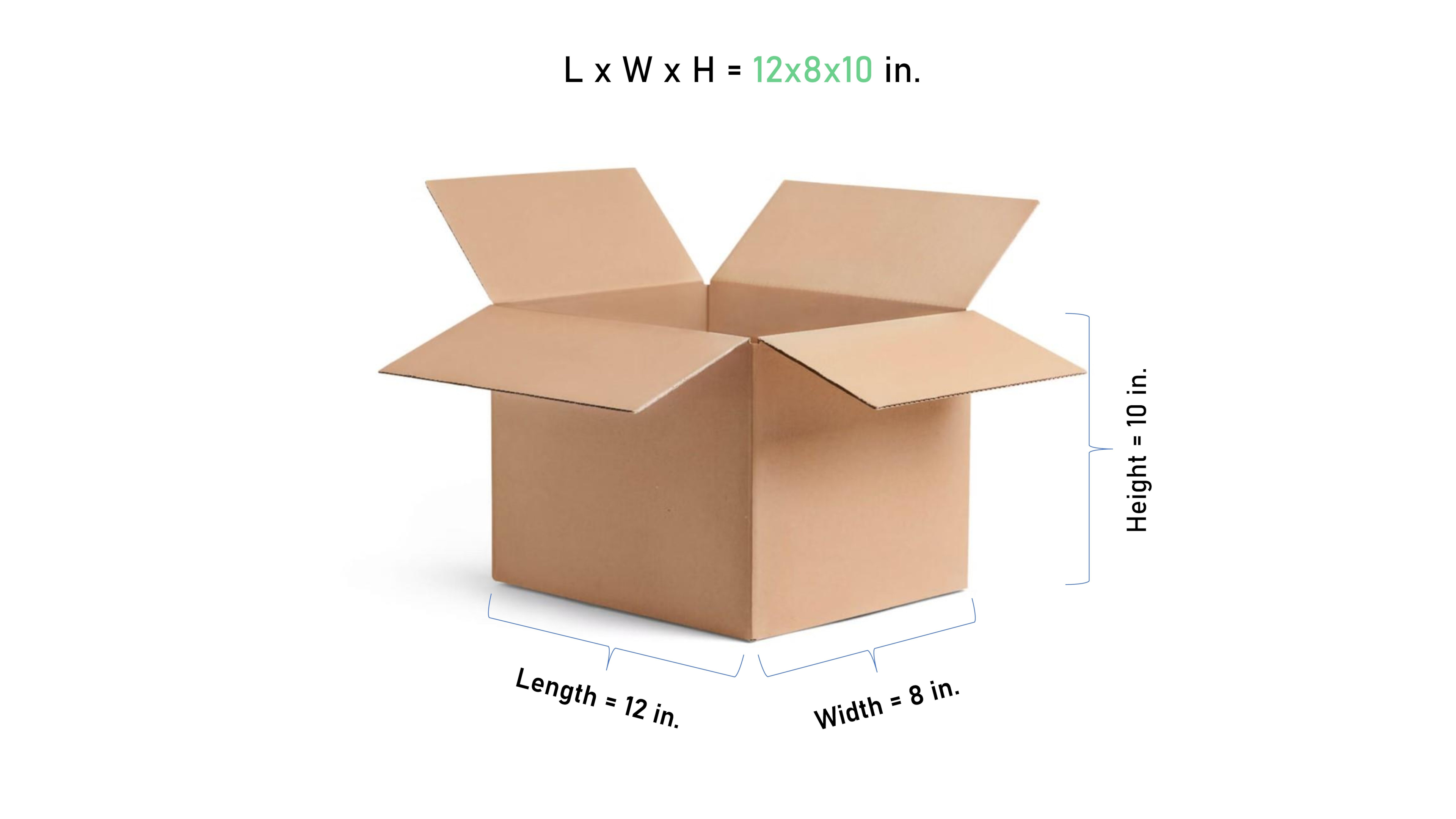

What Does L x W x H Stand For?

All box dimensions are stated in the universal, industry-standard order: Length (L) x Width (W) x Height (H). Understanding these three terms is key to communicating effectively with your packaging supplier.

- Length (L): The longest dimension of the box’s opening.

- Width (W): The shortest dimension of the box’s opening.

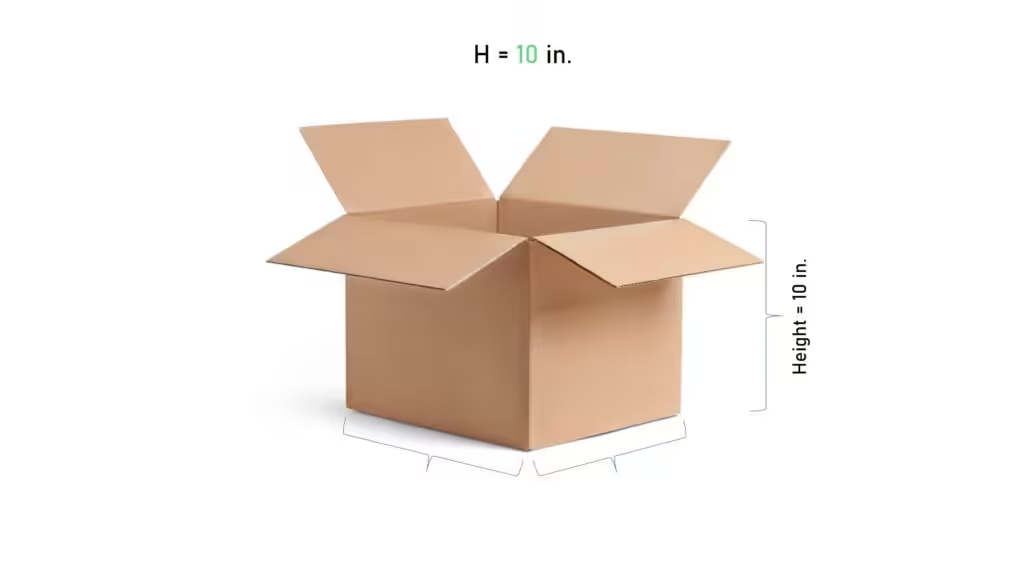

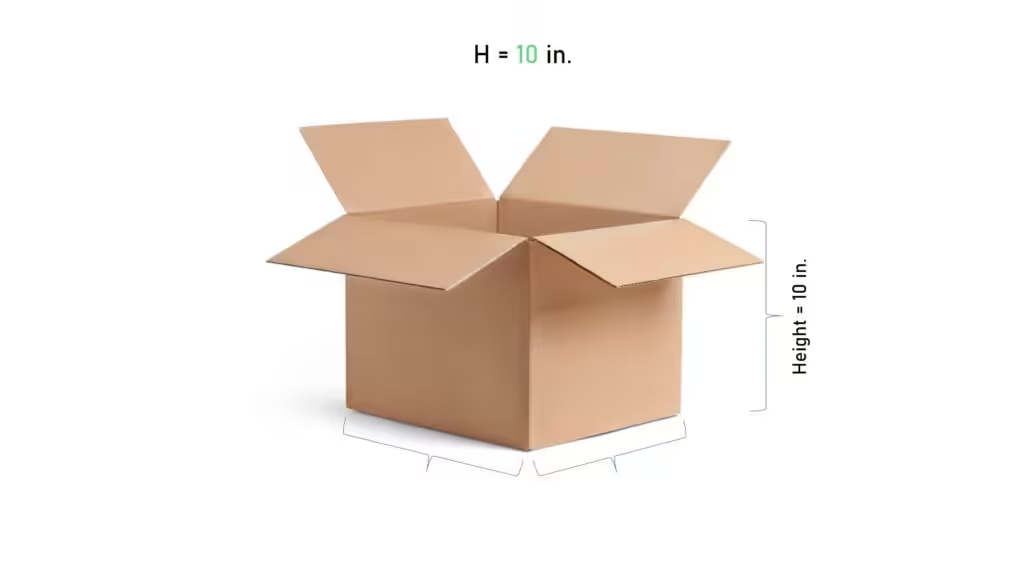

- Height (H): The vertical dimension. This is the distance from the bottom of the box to the top (sometimes referred to as “Depth”).

When you see three numbers listed on a specification sheet, like 12″ x 8″ x 10″, it always translates to:

- Length: 12 inches

- Width: 8 inches

- Height: 10 inches

You can identify the box height by looking at the opening of the lid. The other dimensions will then be the length and width. Now you can determine the length as the larger number; the last remaining horizontal dimension will be the width.

Occasionally, you will see the “H” replaced with a “D” for depth measurement. This is primarily a personal choice by the seller to convey the shape of a product better. In practice, both height and depth refer to the same vertical dimension.

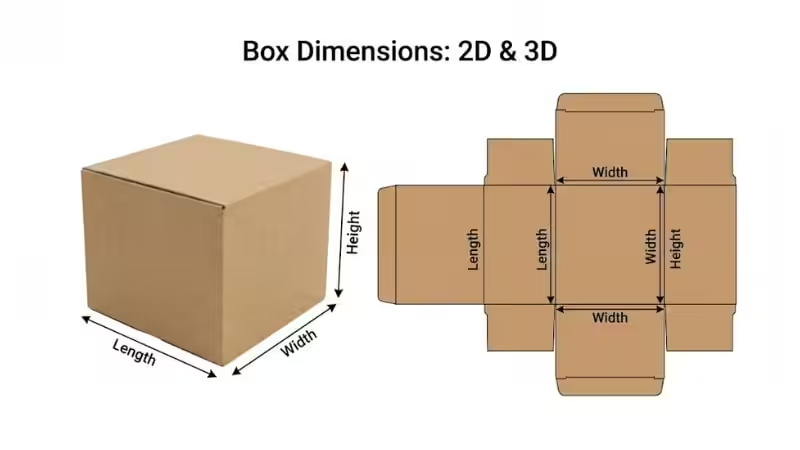

How to Read the Dimensions of a Box: 2D & 3D

In the application of the dimensions above the box packaging, the application and difference between 2D and 3D are used to interpret the dimensions encountered in the process of box packaging, and correctly read the size.

2D Custom Packaging Design

2D box packaging refers to boxes designed using a flat, two-dimensional approach. In contrast to 3D box packaging, which uses a combination of 2D elements and 3D design elements to create a more dynamic and eye-catching packaging solution, 2D box packaging is focused primarily on utilizing two-dimensional surface areas to convey information and branding elements.

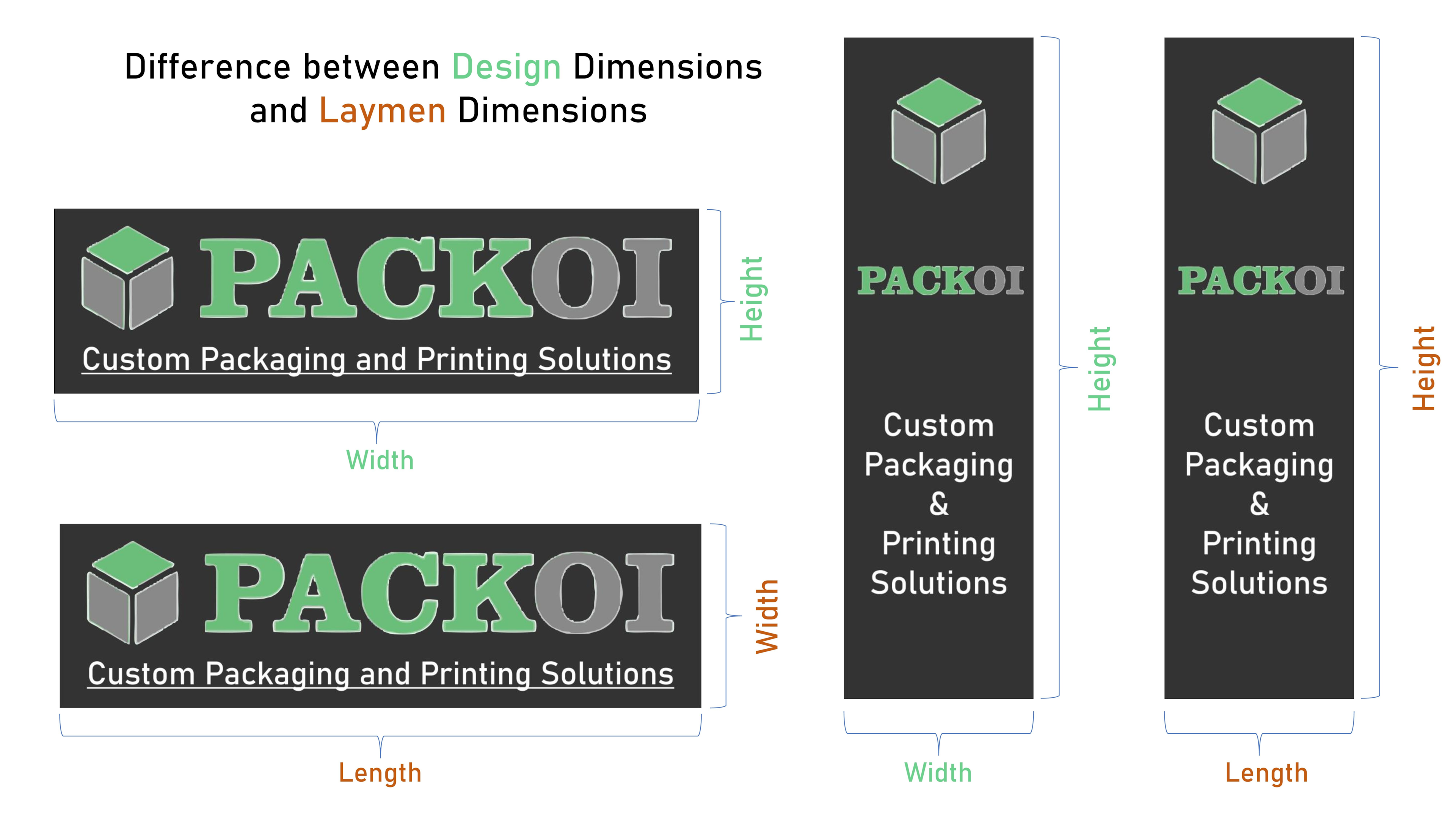

For flat 2D packaging designs, there are only two dimensions: width and height. The term length is less commonly used for flat design in professional environments. However, laymen often use length x width instead of width x height.

Here are some examples of 2D applications in box packaging:

Example 1: Design and Illustration

- Branding – 2D box packaging can utilize large, two-dimensional surfaces to prominently display brand logos, product names, and other messaging.

- Graphics and art – 2D box packaging can incorporate graphics, illustrations, and other 2D elements to create a visually engaging and attractive packaging solution.

- Labels and information – 2D box packaging can include labels, information, and other 2D elements to convey important information about the product, how to use it, and other relevant details.

All design and illustration work uses the standard WxH order for design and prints. The order originates from matrix dimensions in mathematics, but is also standard in digital screen resolutions. Designers use the metric system for their dimensions to avoid relying on fractions.

A vertical A4 design will be written as WxH 210 x 297 mm (8.27 x 11.69 inches). But if you change the orientation to horizontal, the design box dimensions are inverted to 297 x 210 mm, but are still written in the WxH order.

Example 2: Laymen’s Dimensions

Occasionally, manufacturers and printers use LxW (length-width) or LxH (length-height) terms to describe their products. Here, length will always be used to describe the horizontal dimensions relative to the branding and lettering on the packaging.

This order is meant to reduce confusion among buyers unfamiliar with the design industry standards. Generally speaking, people find this method the easiest to understand, but it creates a conflict with industry standards.

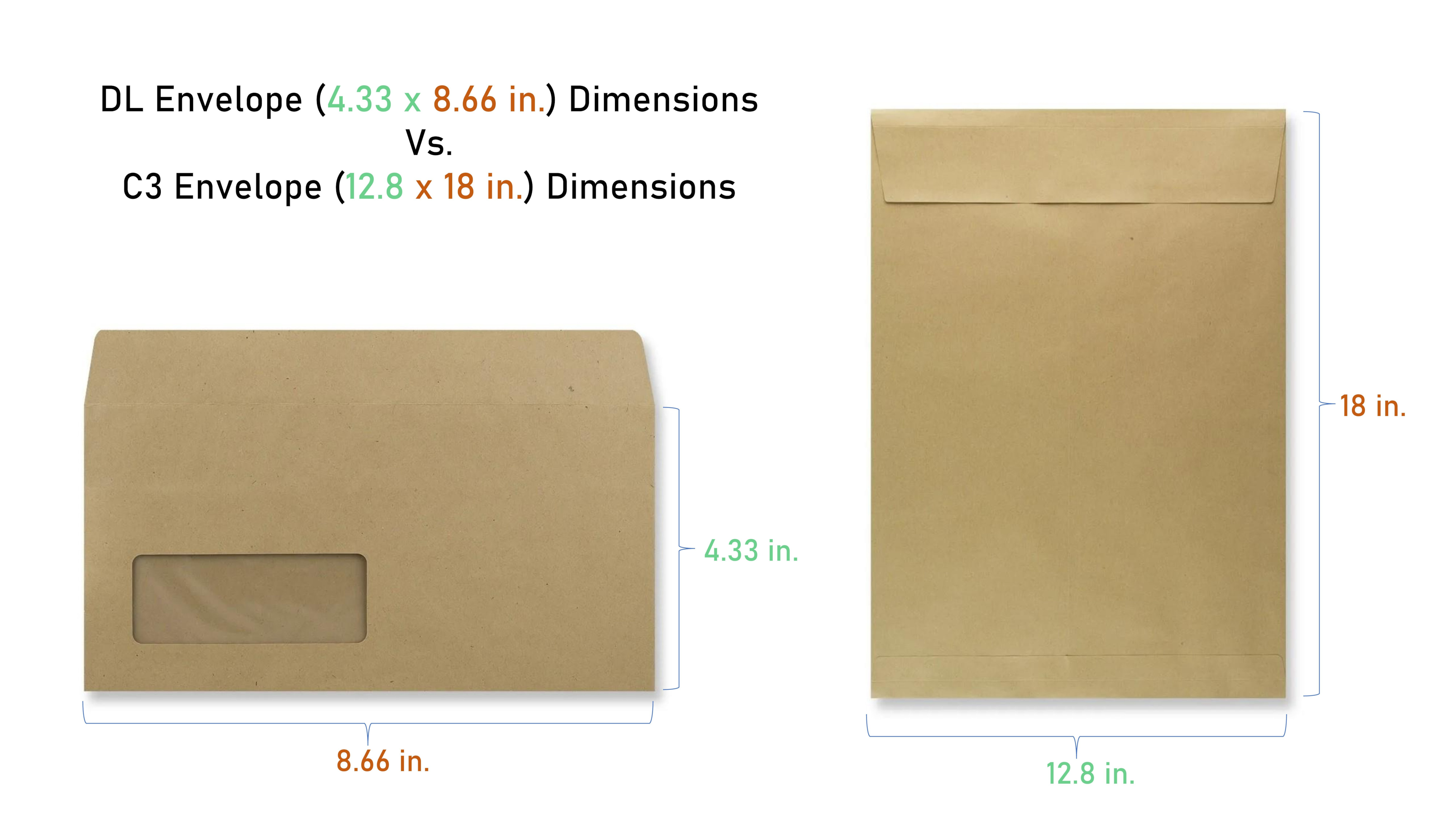

Example 3: Envelope Dimensions

The humble envelope is a key outlier in 2D dimensions. To maintain accurate measurements across several countries, envelope designs have adhered to a non-standard dimension order. All envelopes’ dimensions will have the smaller dimension listed first, irrespective of the orientation.

A regular motivational envelope will be 3.5 x 6 inches, and a vertical open-end envelope will be 9 x 12 inches. There is no standard labeling. You can refer to envelope dimensions as WxH, HxW, or LxW.

Overall, 2D box packaging offers a range of design options and can be tailored to the specific needs and preferences of the product being packaged. By focusing on two-dimensional design elements, 2D box packaging can provide a sustainable and visually engaging packaging solution that effectively protects the product and conveys important information about the brand.

3D Packaging: Step-by-step Guide

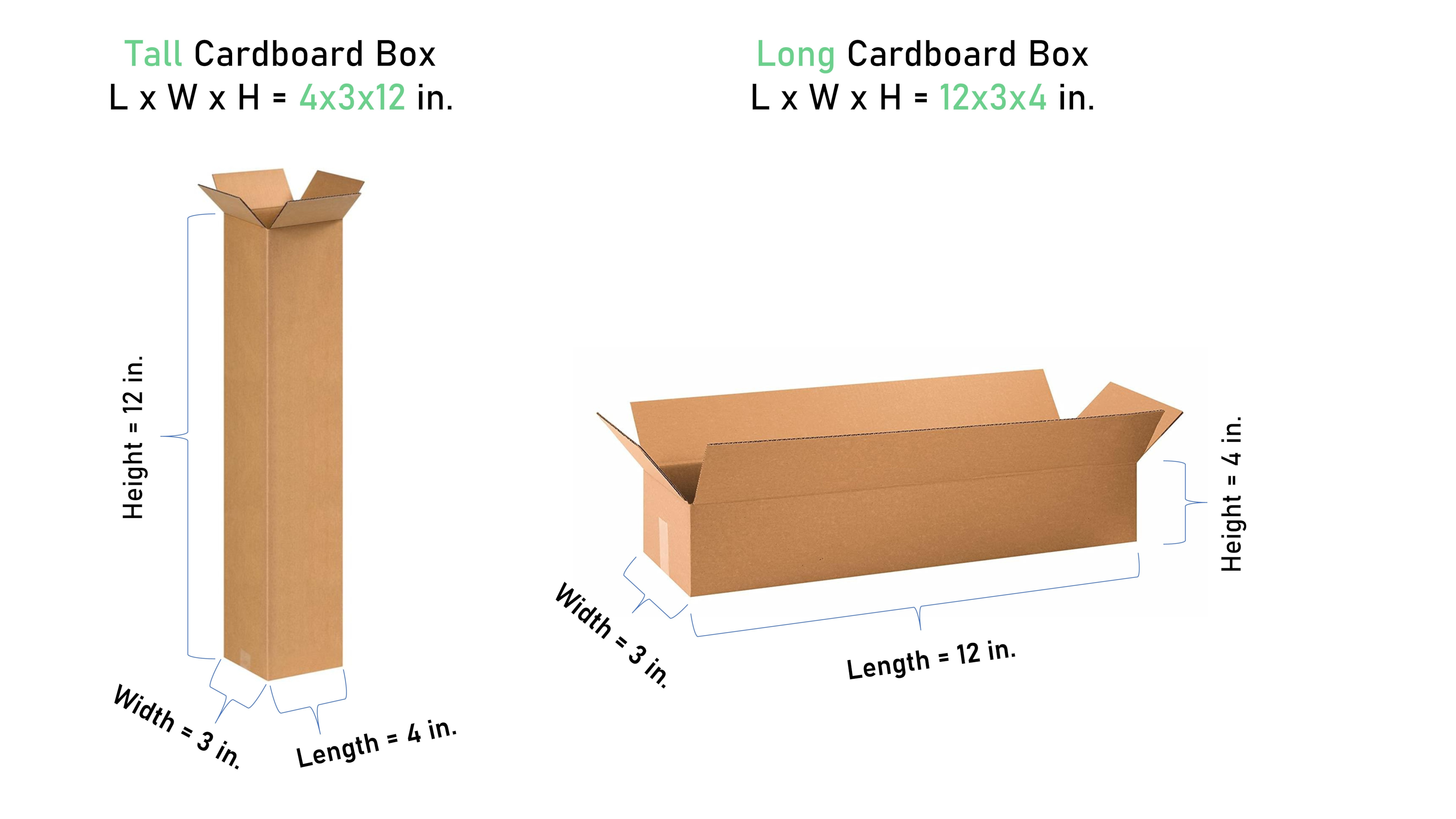

How to measure a box? Standard packaging practice dictates that the order of box dimensions should be listed as length-width-height. All professional box packaging designers and printers follow this order for 3D objects to avoid confusion.

If you see three numbers listed as a product’s size or dimensions, the first number will represent the length, the second the width, and the last the height. That’s 3D. Now, it is also possible to use some 3D tools for 3D design and custom packaging, like Adobe’s 3D packaging design.

Measuring the 3D box and deciphering the box’s dimensions are all step-by-step.

Step 1: Get Your Box Ready

The dimensions for a standard 3D box are written as three numbers separated by the multiplication symbol “x“. These are your length x width x height measurements, in that order. Use a tape measure, if needed, to measure the LxWxH of your box. Let’s assume your box measurements are 12, 8 & 10 inches.

Step 2: Find the Height (H)

Take a look at your box orientation. If your box has a lid, then that side is the top. Your height will be the distance from the top lid to the base of the box. The height of the box is 10 inches, and the remaining length-width is 12 & 8 inches.

Step 3: Find the Length (L)

Now you are left with length-width dimensions. The remaining longest measurement is the length of your box. Now we know the height of the box is 10 inches and the length is 12 inches.

Note: If the box is a perfect square, the Length and Width are the same.

Step 4: Find the Width (W)

Now that we know the height and length of the box, the other dimension must be the width. And now we have associated the three measurements (12-8-10) with the three dimensions (length x width x height).

That’s it! You now have your L x W x H dimensions. Remember to mark the unit of measurement for your size before sending it to your manufacturer to avoid misunderstandings.

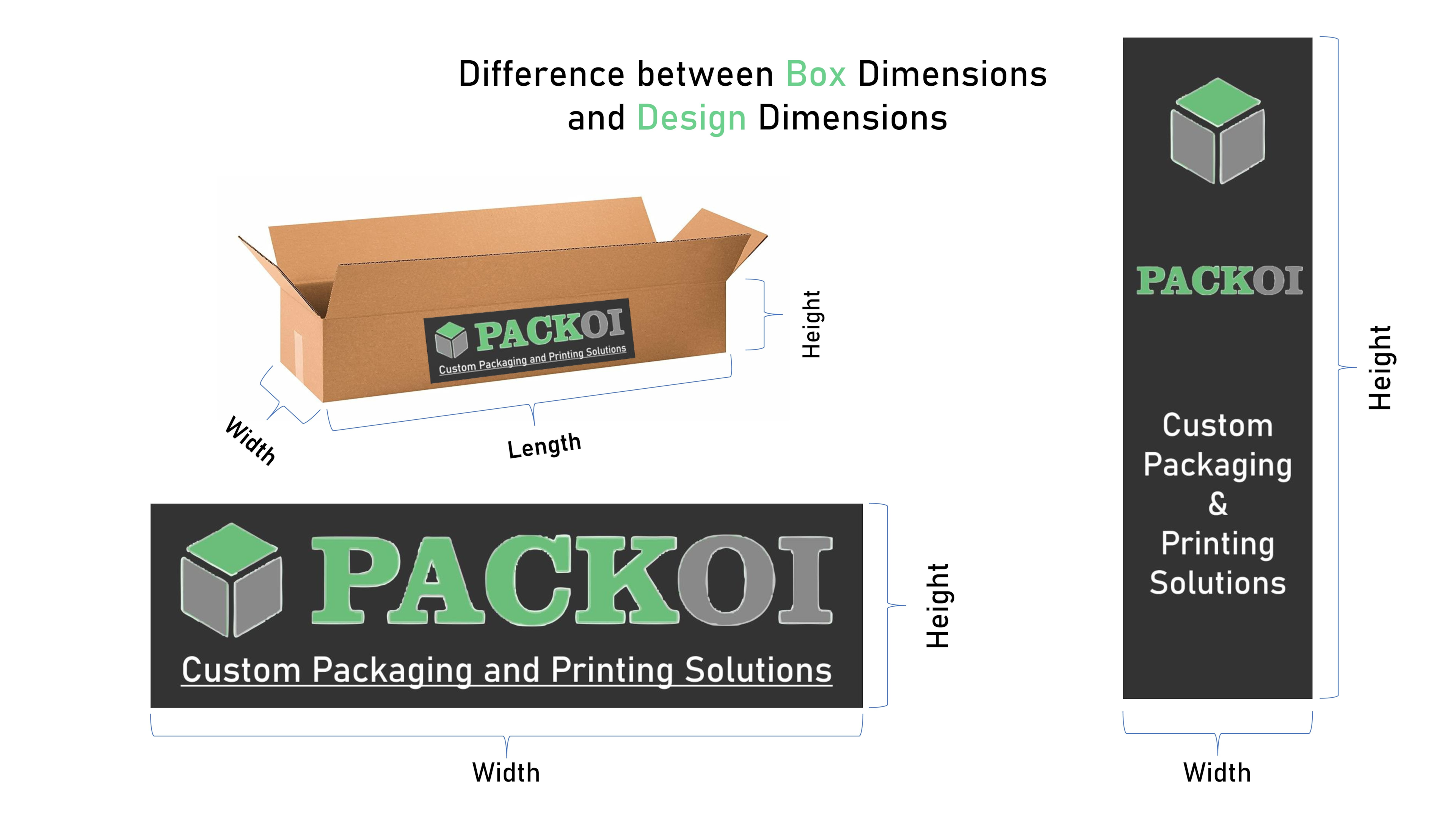

Step 5: Determine Your Orientation

Once you have the physical measurements (L x W x H), you need to decide how the box will be displayed. This determines where your branding goes.

Even though the box dimensions are fixed, your design orientation might change based on how you want the unboxing experience to look.

- Identify the Front: Which panel will face the customer?

- Identify the Top: If it’s a mailer box, the top is usually the lid.

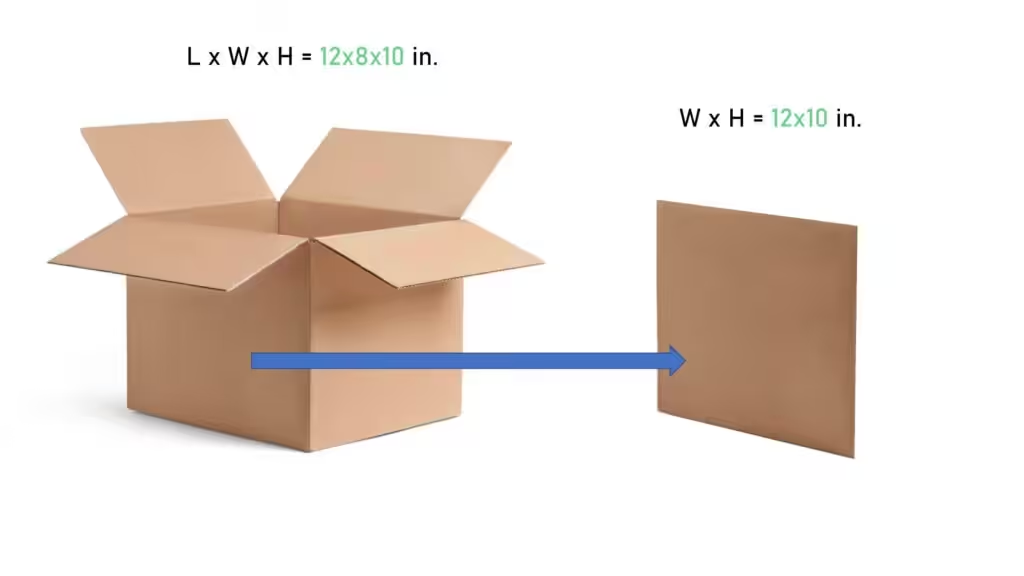

Step 6: Convert to 2D for Design (Print Area)

When you hand these dimensions to a graphic designer, they stop thinking in 3D (L x W x H) and start thinking in 2D (W x H).

In the design software (like Adobe Illustrator), “Length” usually becomes “Width” on the screen. This is why designers ask for “Width x Height”—they are asking for the flat dimensions of the specific print area, not the volume of the box.

If you are designing the Front Panel, you only need the Length and the Height of that specific panel.

FAQs

Q1: How do I measure a box for shipping (e.g., for UPS or FedEx)?

Shipping carriers charge based on volume and weight. They need the External Dimensions (OD). Close and seal your box, then measure the L x W x H of the outside, rounding up to the nearest inch or centimeter to ensure accurate pricing.

Q2: What does “Depth” mean? Is it different from “Height”?

No. In the packaging industry, “Height” and “Depth” are often used interchangeably. They both refer to the same vertical measurement (the “H” in L x W x H). You might see “Depth” used more often with shallow boxes (like pizza boxes), but it is essentially the Height.

Q3: What if I mix up the Length and Width?

For a standard box, mixing up Length and Width usually isn’t a disaster, as the box will just be rotated 90 degrees. However, it does matter for boxes with special print designs or specific opening orientations. It’s always safest to follow the rule: Length is the longest side of the opening.

Q4: Should I leave extra room for packaging materials?

Yes! If you are measuring your product to find the right box size, add a “clearance” buffer to your dimensions. We typically recommend adding at least 0.125″ to 0.25″ to each side of your product’s dimensions to allow for easy insertion and, if needed, protective bubble wrap or tissue paper.

Conclusion

Reading the dimensions for any given product or box will seem daunting at first glance to most people. But the process becomes much simpler once you understand the logic and pattern behind writing dimensions. Try to stick to standard industry practices and avoid relying on laymen and modified box measurements.

Get Your Dimensions Right Every Time with Packoi

Packoi provides state-of-the-art packaging solutions for all industries. We have low MOQs and offer affordable, fully customized boxes and bags. The quality of your packaging indicates the quality of the products inside it. You need to rely on established companies like Packoi to support you in building a successful business.

Contact us today for a free quote, and let’s get your packaging dimensions right the first time.