Last Updated on September 30, 2025 by Packoi Team

Corrugated packaging is an essential component of many businesses. It’s a durable, lightweight, and versatile material used for shipping, storing, and displaying products. But what exactly is corrugated packaging? In this blog post, we’ll define the benefits of corrugated packaging, discuss its history, and explain why it’s important.

We’ll also cover the different types of corrugated containers, box styles, and sizes, analyze the production process and recycling of corrugated packaging and explore its many advantages. We’ll explain why many manufacturers choose corrugated packaging in terms of cost savings, durability, sustainability, safety, and more.

Finally, we’ll look at how modern technologies have improved corrugated packaging design and give tips on choosing the right type for your business needs.

What Is Corrugated Packaging?

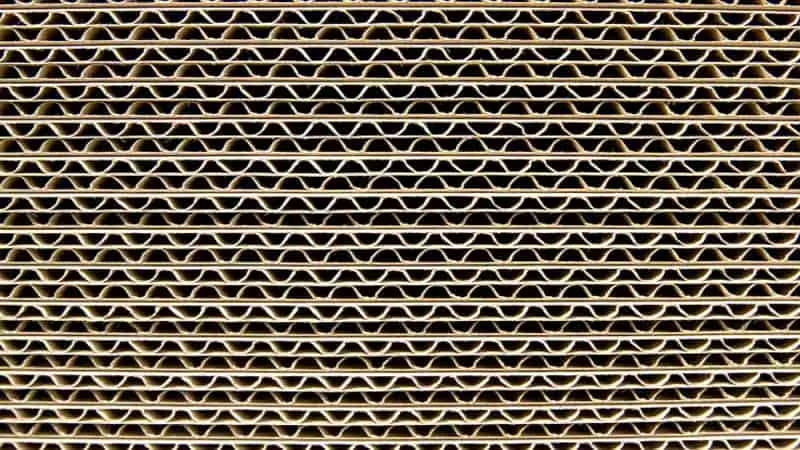

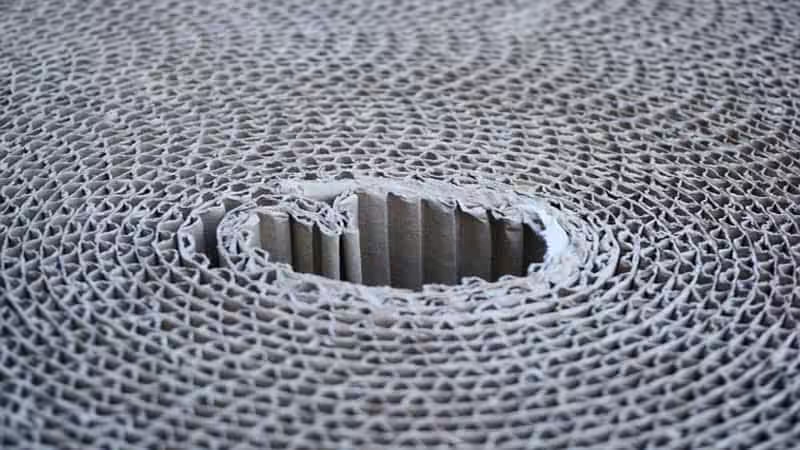

Corrugated packaging is a type of cardboard material made up of three layers: an inside liner, an outside liner, and a fluting corrugated medium sandwiched between the liner sheets between them. The fluting corrugated medium is usually made of kraft paper, which is stronger and more durable than regular paper.

The fluting medium gives corrugated packaging its unique structure and strength, making it ideal for shipping and storing products. Corrugated packaging is commonly used for shipping boxes, retail packaging, cereal boxes, storage boxes, and display stands.

Corrugated packaging has been around for over a century, and its popularity has grown. In the early days, corrugated sheets of packaging were used mainly for shipping heavy items like glass bottles and machinery.

But as technology improved and new materials were developed, the corrugated sheets of packaging became more versatile and customizable.

Today, corrugated packaging is used in various industries, including food and beverage, automotive, electronics, and more. It’s a cost-effective, eco-friendly option that provides excellent product protection during shipping and handling.

What Are the Different Types of Corrugated Cardboard Box Styles and Sizes?

Corrugated cardboard packaging comes in various styles and sizes, each designed for specific purposes. Here are some of the most common types of corrugated box styles and sizes:

1. Regular Slotted Container (RSC)

The RSC containerboard is the most common type of corrugated box, with rigid boxes with flaps that meet in the middle and can be taped or glued shut. This type of corrugated board box is ideal for shipping and storage.

2. Full Overlap Container (FOL)

The FOL has flaps extending over the entire box width, providing extra protection for the contents inside. This type of box is commonly used for heavy items like appliances and machinery.

3. Half-Slotted Container (HSC)

The HSC has no top flaps and is designed to be used with a separate lid. This type of box is ideal for products with specialized equipment that needs to be quickly accessed, like produce and electronics.

4. Five-Panel Folder (FPF)

The FPF has a single piece of corrugated material that’s scored and folded to create five panels of flat material. This corrugated board or box is commonly used for books, picture frames, and other flat items.

5. Telescoping Box

The telescoping box consists of two pieces that fit together to form a box of the same length and adjustable height. This type of box is commonly used for shipping irregularly shaped items.

Corrugated boxes come in various sizes and dimensions, ranging from small shipping boxes to large storage boxes. Choosing the right size and style of a cardboard box for your specific shipping needs is essential to ensure maximum protection and cost-effectiveness.

Analysis of the Production Process and Recycling of Corrugated Packaging

The production process of corrugated packaging begins with the creation of the fluting medium. The kraft paper is run through a corrugating machine, which creates the fluted medium pattern by pressing the paper between two sheets of corrugated rolls.

The fluting medium is then glued between three sheets of two liner boards and two sheets of thick paper stock, both of which are made of high-quality, smooth paper that provides a surface for printing and labeling.

Corrugated packaging is a highly sustainable material, with a recycling rate of over 90% in the United States. The recycling process begins with collecting used corrugated boxes, which are then transported to a recycling facility. The corrugated boxes are sorted, cleaned, and pulped to create new paper products, including new corrugated boxes.

Recycling corrugated packaging saves energy and resources, reduces landfill waste, and helps preserve natural habitats. Many businesses and consumers prioritize sustainability, and using corrugated packaging can be essential to their environmental efforts.

What Are the Advantages of Using Corrugated Packaging?

Corrugated packaging offers many advantages over other materials, including:

- Cost-Effectiveness: Corrugated packaging is an affordable option for shipping and storage, with lower material and shipping costs than other materials like plastic and metal.

- Durability: Corrugated packaging is solid and sturdy, providing excellent product protection during shipping and handling.

- Customizability: Corrugated packaging can be easily customized to fit the specific needs of a business, with options for printing, labeling, and sizing.

- Sustainability: Corrugated packaging is a highly sustainable material with a high recycling rate and minimal environmental impact.

- Safety: Corrugated packaging is a safe option for shipping and handling, with no sharp edges or dangerous materials.

The Benefits of Using Corrugated Packaging Over Other Materials

When it comes to choosing the right packaging material for businesses, it’s important to weigh the pros and cons of each option. Corrugated packaging is an excellent choice for many businesses, but how does it compare to other common packaging materials like plastic, metal, wood, and glass?

1. Plastic

Plastic is a popular packaging material due to its durability and flexibility. However, it’s important to note that plastic is not environmentally friendly. Plastic can take hundreds of years to decompose, harming wildlife and ecosystems.

In contrast, corrugated packaging is made from renewable materials like paper and is highly recyclable, with a recycling rate of over 90%.

2. Metal

Metal packaging is durable and can provide excellent product protection during shipping and handling. However, metal is heavier and more challenging to handle than corrugated packaging, leading to higher shipping and handling costs.

Corrugated packaging, on the other hand, is lightweight and easy to operate, making it a more cost-effective option for many businesses.

3. Wood

Wood is a popular packaging material for heavy or bulky items. However, wood can be expensive and difficult to handle, and its recycling rate is much lower than that of corrugated packaging. Additionally, corrugated packaging is more customizable than wood, allowing businesses to create packaging that fits their specific needs.

4. Glass

Glass is an excellent packaging material for shipping products and materials that require high levels of protection, such as liquids and fragile items. However, glass is heavy and can be expensive to ship. Corrugated packaging is a more cost-effective option for many businesses and provides better product protection during shipping and handling.

While there are advantages to using other packaging materials, corrugated packaging offers unique benefits, making it an excellent choice for businesses.

Corrugated packaging is cost-effective, sustainable, and customizable, providing excellent product protection during shipping and handling.

Compared to other materials like plastic, metal, some wood fibers, and glass, corrugated packaging is a highly versatile and functional option for businesses.

Why do Many Manufacturers Choose Corrugated Packaging?

The cost-effectiveness, durability, sustainability, safety, and customizability of corrugated packaging make it a popular choice among manufacturers. One of the primary reasons businesses choose a corrugated material for packaging is its cost-effectiveness.

Compared to other packaging materials like metal or wood, corrugated packaging is much lighter and cheaper to ship. This means that businesses can save on shipping and handling costs, making it a more affordable option for businesses of all sizes.

Additionally, corrugated fiberboard packaging is highly durable, making it ideal for protecting products during shipping and handling. The multiple layers of paperboard provide excellent cushioning and protection, preventing product damage during transport.

This durability also makes the corrugated fiberboard material packaging a safer option for shipping hazardous or fragile materials.

Sustainability is another critical factor driving the popularity of corrugated packaging, and it’s worth mentioning that sustainable packaging can help your business stay competitive.

Corrugated packaging is highly recyclable and made from renewable materials like recycled paper. The recycling rate for corrugated packaging is over 90%, making it an excellent option for businesses looking to reduce their environmental impact.

Furthermore, corrugated packaging is customizable, allowing businesses to create packaging that meets their specific needs. With printing, labeling, and sizing options, businesses can create unique packaging that enhances their brand and protects their products.

Corrugated packaging can also be easily designed to fit specific products, reducing the need for additional packaging materials and minimizing waste.

Overall, the cost-effectiveness, durability, sustainability, safety, and customizability of corrugated packaging make it a popular choice among manufacturers. Its lightweight nature and easy recyclability make it an eco-friendly option, while its customizability allows businesses to create packaging that fits their unique needs.

How Have Modern Technologies Improved Corrugated Packaging Design?

Corrugated packaging has come a long way since its early days, and modern technologies have significantly enhanced its design and functionality. The advancements in printing technology have profoundly impacted how businesses use their corrugated box packaging for branding and marketing purposes.

With the ability to print high-quality graphics and images directly onto corrugated cardboard boxes, businesses can now leverage this valuable space to showcase their brand and product information in a visually compelling way.

Digital printing has further revolutionized the way businesses approach corrugated packaging design. It allows for customizations in small quantities, making it more accessible and cost-effective for small businesses.

Moreover, digital printing has enabled businesses to print variable data, such as barcodes and QR codes, making tracking inventory easier and improving supply chain efficiency.

UV and water-based inks have also been a significant development in corrugated packaging technology. These inks offer higher durability, better resistance to moisture and humidity, and improved eco-friendliness.

They are also safer for the workers who handle them, making them a better option for businesses that prioritize the safety and well-being of their employees.

In addition to printing technology, modern technologies have also contributed to the structural design of corrugated packaging. Creating new and various box designs, construction styles, and features has dramatically improved the functionality of corrugated packaging, making it more versatile and adaptable to different products and use cases.

For example, tear strips have been introduced in some corrugated cardboard boxes, allowing easy opening without the need for cutting tools. This makes it more convenient for the end-users and reduces the risk of damage to the product during the opening process.

Modern technologies have significantly improved the design and functionality of corrugated fiberboard packaging. The corrugated packaging industry has come a long way, from high-quality printing and customizations to new structural support features and designs.

At Packoi, we stay ahead of the curve by leveraging the latest technologies to provide our clients with cutting-edge corrugated packaging solutions that meet their unique needs.

Other modern innovations in corrugated packaging design include:

- Moisture-resistant coatings that protect products from moisture damage during shipping and storage.

- Advanced adhesives that provide stronger bonds and improved box construction and integrity.

- Computer-aided design (CAD) software that allows for precise and efficient box design and production.

- Automated box-making machines that can produce high volumes of corrugated boxes quickly and efficiently.

How to Choose the Right Type of Corrugated Packaging for Your Business Needs

Choosing the right type of corrugated packaging for your business needs involves several factors, including product type, shipping requirements, storage needs, and budget. Here are some tips for selecting the right type of corrugated packages:

1. Consider the Product Packaging Type

Different products have different packaging requirements. For example, fragile items may require extra cushioning, while heavy items may require a more substantial box.

With fragile items, you can choose solid fiberboard sheet stock. Making fiberboard shipping boxes is the best solution to protect your products during shipping. If items are less fragile, you can choose cardboard box designs for your shipping needs.

2. Evaluate Your Shipping Material Requirements

If you’re shipping products long distances or through harsh conditions, you’ll need packaging that provides adequate protection. Corrugated boxes are the best when it comes to shipping products. Whether the items are fragile or not, a corrugated box will give you the right solution for your packaging needs.

If you make corrugated cartons, your items will always be safe no matter the distance you are shipping.

3. Assess Your Storage Needs

If you store products in corrugated boxes for extended periods, you’ll need containers that can withstand the elements and maintain their structural integrity well. Continually evaluate the specific storage need before settling for any corrugated box design.

It is important to have corrugated boxes that meet your specific requirements. Storage corrugated cartons should be solid and durable for proper results.

4. Consider Your Budget

Corrugated packaging comes in various styles and materials, with varying costs. Choosing packaging that meets your needs while staying within your budget is essential.

Exploring New Trends in Corrugated Packaging for Businesses

As technology and consumer demands continue to evolve, new trends in corrugated packaging are emerging. Here are some of the latest trends in corrugated packaging for businesses:

1. E-Commerce Packaging

With the rise of e-commerce, businesses are looking for ways to create product packaging that’s both functional and visually appealing. New packaging designs are emerging with colorful feature graphics, easy-open features, and protective cushioning.

2. Sustainable Packaging

Businesses are increasingly looking for ways to reduce their environmental impact and are turning to sustainable packaging solutions. This includes the use of biodegradable and compostable materials, as well as implementing recycling programs for corrugated packaging.

3. Smart Packaging

With the increasing use of technology, smart packaging is becoming more popular. This includes packaging incorporating sensors, RFID tags, and QR codes to give consumers real-time information about the product and its origin.

4. On-Demand Packaging

As businesses look for ways to reduce waste and cut costs, on-demand packaging emerges as a viable solution. This involves using machines to create custom packaging on-site, reducing the need for excess inventory and reducing transportation costs.

Exploring these new trends in corrugated packaging can help businesses stay ahead of the curve and provide their customers with innovative and sustainable packaging solutions.

FAQs

Q1: What are the main types of corrugated boxes?

Common types include Regular Slotted Container (RSC), Full Overlap (FOL), Half-Slotted (HSC), Five-Panel Folder (FPF), and Telescoping Boxes.

Q2: Can corrugated packaging be recycled?

Yes, corrugated packaging has a recycling rate of over 90% and is one of the most sustainable packaging options.

Q3: What industries use corrugated packaging?

It’s widely used in food and beverage, e-commerce, electronics, automotive, and retail industries.

Q4: How does corrugated packaging compare to plastic or metal?

It’s lighter, more cost-effective, and more sustainable than plastic or metal packaging.

Q5: What modern technologies are used in corrugated packaging?

Technologies like digital printing, UV inks, CAD design, and moisture-resistant coatings have enhanced corrugated packaging.

Conclusion

In conclusion, various industries have widely adopted corrugated packaging due to its versatility, durability, and sustainability. Corrugated packaging is an excellent choice for shipping, storing, and displaying products, providing a cost-effective and environmentally friendly packaging option for businesses of all sizes.

The different types of corrugated box styles and sizes, along with modern technologies that have improved corrugated packaging design, make it easier for businesses to choose the right type and benefits of corrugated packaging that suits their needs.

Overall, corrugated packaging continues to be a popular and reliable packaging option for businesses looking for efficient and eco-friendly ways to package their products.

At Packoi, we offer various corrugated packaging solutions for various industries. Whether you need custom-designed boxes, die-cut boxes, or standard boxes, we have you covered. Contact us today to learn more about our packaging solutions and how we can help your business grow.