Last Updated on March 3, 2025 by Packoi Team

Some individuals choose the project binding method based on the page count. Saddle stitch binding is used for projects with less than 48 pages, whereas perfect binding is used for publications with more than 96 pages.

However, there is much more to these binding methods than this simple concept. Furthermore, what happens if your project has multiple pages, like 48 and 96 pages? When you have something to get printed, binding is one of the most critical options you can make that will significantly impact the cost and appearance of your book or project.

Fortunately, most printers are pretty educated about this issue and can generally point you in the correct direction when selecting an acceptable binding method for your job.

Nonetheless, it’s always a good idea to know your options and grasp each strategy’s advantages and disadvantages. So please put on your thinking cap, and let’s speak about binding!

What Exactly Is Binding?

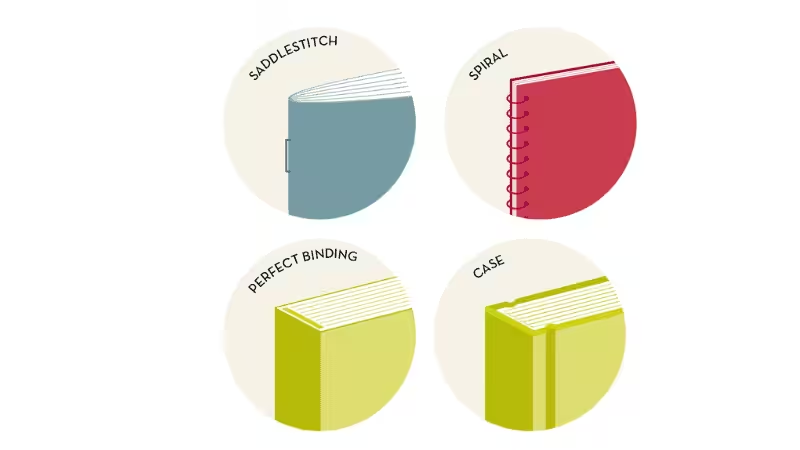

Binding, as the name implies, is the process of joining the page count of a print job together. There are other binding techniques too, but we’ll focus on two of the best bookbinding methods and the difference between saddle stitch and perfect binding.

Learn the best applications and distinctions between perfect binding and saddle stitch; the cost reductions associated with different bindery alternatives; bindery-related printing industry terminology; and how to calculate the spine thickness of your publication.

The thickness of the print materials, as well as the manufacturing procedure, have a considerable impact on the binding method used. Keeping this in mind, we’ll delve more into the specifics of these two binding possibilities. Once you have all the pertinent information, you can choose the best binding for your project.

What Is Perfect Binding?

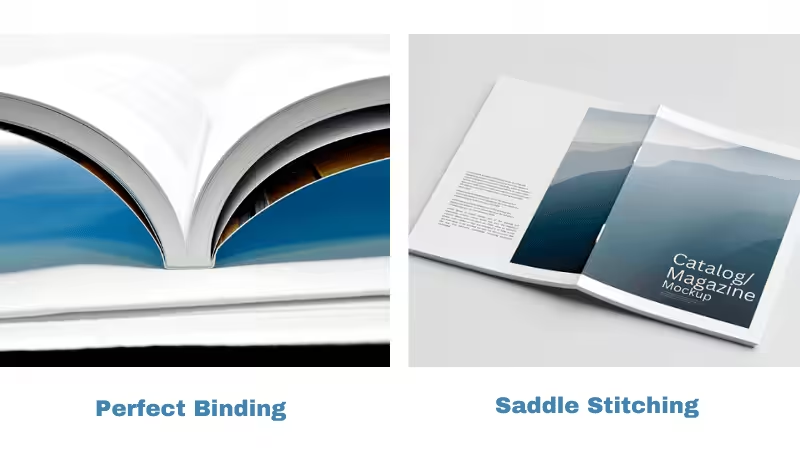

Perfect binding is a popular binding style used for most soft-cover books, like comic books, coffee table books, magazines, catalogs in bookstores, manuals, technical guides, catalogs, and any other book that has 64 pages where cost is an issue.

Perfect-bind books are made of sturdy stock and feature a flat spine to which the enclosing pages are attached. Perfectly bound books provide a cleaner, more professional appearance than saddle-stitched books. The pages are all the same length and are cut flush with the cover.

The disadvantage of the flawlessly bound binding technique is that it is challenging to lie completely flat and can be worn with frequent use.

When Should You Use Perfect-Bound?

A perfect-bound book typically has a higher page count. Perfect binding is binding a magazine using glue rather than staples. Perfect binding is recommended for every publication with more than 68 pages.

The spine of a perfect-bound booklet is flat. Including a copy on the spine of perfect-bound books is recommended to make your book stand out on a bookshelf and for easy identification. The saddle-stitch method cannot accommodate higher numbers of pages.

However, depending on the number of magazines, the quality of the paper, and other external factors, the cost difference between these two approaches can range from $500 to $10,000.

Advantages of Perfect-Bound Bookbinding

- Professional finish: Provide clean edges and square ridges, look professional, and make it easier to attract attention when displaying.

- Cost-effective: For medium to large print runs, it can be economically produced without sacrificing the quality of the finished product.

- Enhanced durability: Adhesives used in binding can create a strong bond, making the page stronger and more durable.

- Spine printing capability: Hardcover books have spines wide enough to support printing, allowing titles and graphics to be added to shelves for easy identification and enhanced visual appeal.

- Variable page count: not limited by the number of pages. It can handle a large number of pages, making it suitable for a wide variety of books, from thin manuals to thick novels.

- Customizable design: Provides flexibility in design and formatting to accommodate a variety of book sizes and allows for creative cover designs, including the use of different materials and finishes.

Limitations of Perfect Binding

- Minimum page count: The ideal page count for perfect binding is between 16 and 36 pages, with 24 pages being the standard. If the page count is too low, the book may not be thick enough to bind securely, and if the page count is too high, the book may become too thick and difficult to handle.

- Type of paper: Perfect binding is generally not suitable for use with thick, heavy paper stocks, such as cardstock or cover stock. The paper used for perfect binding should be fairly lightweight and pliable, and it should be able to bend easily without causing damage to the book.

- Size restrictions: Perfect binding is typically not suitable for books that are very large or very small. Books larger than 8.5 x 11 inches or smaller than 5.5 x 8.5 inches may not bind properly, leading to a poorly constructed book.

- Content restrictions: Perfect binding is generally not suitable for use with documents or books that will be subject to frequent use or handling. This is because the perfect binding is not as durable as other binding options, and it may not hold up well over time in high-use environments.

What Is Saddle Stitching?

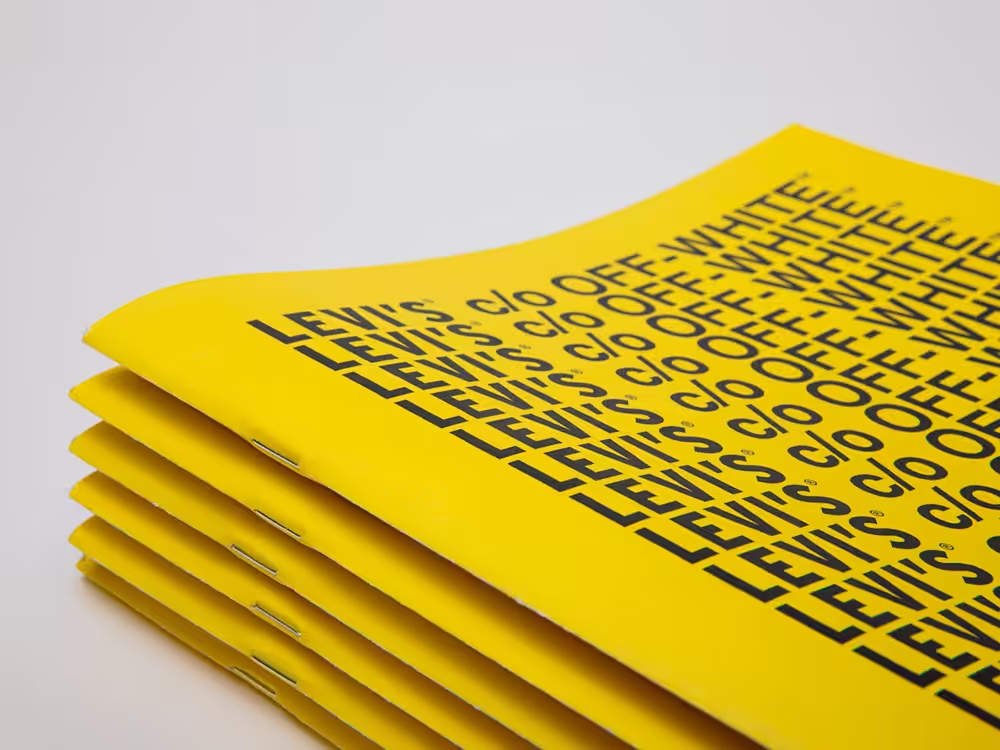

Undoubtedly, saddle stitch binding is one of the most popular binding options. Many pages are glued together with staples along the spine. This basic binding technique is only appropriate for print projects up to 48 pages.

Saddle stitch books are made in multiples of four pages, meaning that four distinct book pages are manufactured for every page folded in half. This does not include the front and back covers.

When saddle stitch binding is used, folded sheets are collected together with sheets nested inside one another from the center to the cover and wire staples are used to staple the inside pages through the fold line.

Saddle stitch is frequently used in magazines, periodicals, programs, and other books where cost is considered. Because the pages are nested, the material creates a “creep” in the pages.

After the book has been trimmed, the creeping of the nested sheets causes the pages to become smaller as you approach the center. Furthermore, the more pages there are, the more likely the staples will fail and the more difficult it will be to staple them.

For these reasons, saddle stitching a book or pamphlet with more than 64 pages is usually not brilliant.

When Should You Use Saddle-Stitch?

Multiple sheets are saddle-stitched together at the fold with two or three staples. The spine of a saddle-stitched magazine is sometimes known as the fold.

Saddle stitching is used to bind booklets with 8 or more pages. The booklet must be on page multiples of 4 for the saddle stitch binding option to work.

For publications with fewer than 68 pages, saddle stitching is recommended. It is also less expensive and ideal for regularly published publications.

The limitation on the number of pages that should be contained in a saddle-stitch booklet is related to a phenomenon known as page “creep,” which we have discussed above in more detail.

Advantages of Saddle Stitching

- Cost-effective: One of the most economical binding methods, it is an excellent choice for projects with smaller budgets and lower page counts.

- Fast production: The saddle splicing process is simple and quick, allowing for faster turnaround times in printing.

- Flat opening: The saddle seam material can lie relatively flat when opened, which is easy to read and handle and is ideal for making manuals, brochures, and catalogs.

- Lightweight: This binding method adds very little weight to the finished product, keeping the overall weight of magazines and brochures to a minimum.

- Versatile: Saddle-shaped nails can be used in a variety of materials, including thick paper covers and a variety of paper inside pages.

- Low page adjustment: This is ideal for documents with low page counts that do not require the thickness required for perfect binding.

- Convenience: The compact and bound nature of saddle-sewn books makes them easy to distribute and transport.

Limitations of Saddle Stitching

- Wire stitching is hard on the paper and is not advised for pieces that will be used frequently.

- There are only a few paper variants inside the book. For example, if you combine two 16-page forms to make a 32-page brochure and want pages 4 and 5 to be red paper, pages 1 through 8 and 23 through 32 will likewise be red paper.

- Lack of a printable spine

- Thickness restrictions. Documents denser than 125.25 inches may necessitate a different binding procedure.

- Creep may necessitate particular design adaptations, particularly in tiny sizes with more significant page counts.

Which Binding Is Best for You?

The binding styles have evolved significantly over time, with contemporary perfect bound procedures providing a durable, economical choice that looks fantastic. Saddle stitching has, over the years, become a popular choice for fewer pages due to its inexpensive cost, compact size, and durability.

Saddle stitch and perfect binding are currently the most popular alternatives for brochures.

Saddle stitching is typically less expensive and maybe a better option for tiny booklets or pamphlets. If you are planning a larger project, you should use perfect binding. It will appear more solid and expensive, making it a better choice if your magazine, brochure, booklet, or book needs to impress people.

Folded brochures for fewer pages and perfect bindings for longer books are two further alternatives to explore. If you require assistance selecting the best binding for your project, don’t hesitate to contact us.

Cost of Binding

Whatever binding option you choose, printers typically charge two fees for the binding process: the make-ready price (the cost of setting up the machine) and the cost per 1,000 copies.

For reference, the rates listed below are typical charges for perfect binding or saddle stitching in 64-page Plus Cover magazines. (Increasing the number of pages eventually raises both the make-ready and the per-thousand running costs.)

Conclusion

To conclude, selecting the appropriate one can ensure that your book, magazine, or pamphlet can withstand years of use and reading or that it will pack neatly for shipping. A binding finish is the ultimate touch to any printed object; it holds everything together with metal, glue, or wire.

For a bit of publication that isn’t designed to remain forever, saddle stitch will serve. Saddle-stitched binding is appropriate for pamphlets and brief periodicals. In contrast, a perfect binding is appropriate for a publication that will be reread. Perfect binding is appropriate for softcover books or bulkier magazines with variable paperweights.

Because information can be printed on the spine, perfect binding is also the most fantastic solution for a publication that will be stored on a bookshelf.

Packoi Printing Could Help You Choose the Matching Book Printing.

These alternatives may work for you in a small area but are limited to specific paper thicknesses. Packoi Printing will assist you in selecting the best binding approach for your printing needs.

Contact us with your requests, and our professionals will clear up any confusion. Our state-of-the-art printing and binding options result in a high-quality, completed product.

If you’re considering binding your next print project, keep the number of pages per unit and the breadth of the project in mind for distribution considerations. Packoi Printing’s finishing expertise can assist you in making an informed, effective option within your budget.