Last Updated on June 26, 2023 by Packoi Team

Protecting and preserving the condition of these medical devices require safer and more secure packaging. Most of the medical equipment is expensive, and damage to any can lead to serious losses.

This article will serve as a guide to safe and secure medical device packaging, looking at its importance and the protective functions packaging plays in the medical industry.

Why Packaging is Important in Medical Devices

Ensuring Product Integrity and Sterility

Medical devices and vital equipment used in preventing, diagnosing, and treating human diseases and compromising their integrity or sterility may seriously threaten human life.

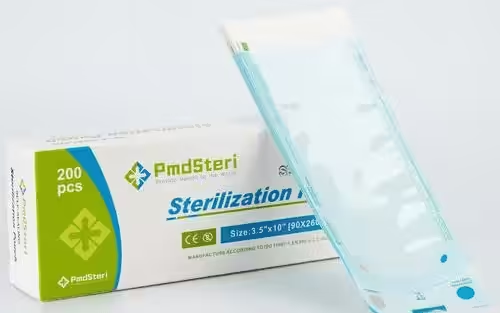

- Maintaining sterility in medical devices: The integrity of a medical device’s packaging must endure the shelf life of the equipment. Package integrity determines the sterility of a medical device. The medical device packaging must allow sterilization and maintain the medical equipment’s sterility until the use time. The packaging material must be strong enough to withstand shipping physical and environmental hazards throughout the supply chain.

- Preventing contamination and preserving the device’s integrity: Various forms of contamination may render the device unusable. The medical device packaging must be free from cracks, holes, tears, and other openings that may allow foreign substances like dust and other residues to contaminate the medical device. To determine whether the packaging can preserve the device’s integrity, package integrity testing is essential.

- Compliance with regulatory standards for sterile barrier systems: ISO 11607 is a standard used in medical packaging that specifies the requirements and testing methods for packaging products or sources, sterile barrier systems, and packaging processes that will ensure medical devices maintain their integrity and sterility until the point of use. Package integrity testing is important to ensure the sterile barrier system has no detectable punctures, channels, or paths that may allow microbes to enter the system. Also, the package must allow for aseptic presentation to prevent microbial contamination. The FDA regulations also require barrier systems to undergo package strength testing. Packaging and seal strength are the two main aspects being determined in this process. The packaging strength helps to show the package is strong enough to contain the medical device after distribution or aging. Seal strength also allows the packaging manufacturer to confirm the sealing process adheres to required standards and can be reproduced. When performed together, these testing can prove that the sterile barrier system is tough and suitable for maintaining the integrity of the medical device.

Protecting Against External Factors

- Identifying potential risks during storage and transportation: There are potential risks during the storage of medical devices. The main potential risks include contamination, fluctuating temperatures, breakages, and unfavorable shipping conditions. All these risks can lead to losing the integrity of the product packed. An effective packaging system should help to minimize the effect of external risk factors and protect medical devices against losing their integrity.

- Shielding devices from moisture, light, and physical damage: Moisture, light, and physical impact are some of the external factors compromising the performance requirements of medical devices. A medical device package must shield the packaged product from moisture and light, which may damage the entire equipment and render it unusable. Some degree of UV light can damage medical equipment. On the other hand, moisture can cause rusting of parts of the medical device. Also, since moisture content may have impurities, contamination is likely when in contact with medical instruments. Physical damage is more common during transportation, and robust packaging with the required seal strength and package strength will help reduce the risk of damaging medical devices in unfavorable shipping conditions.

- Maintaining the functionality of medical equipment: The functionality of a medical device is determined by its integrity. Medical equipment packaged with a packaging system that has passed the integrity and strength tests will have sustained integrity and functionality.

The Protective Functions of Medical Device Packaging

Packaging offers a number of protective functions to the medical devices packaged. The protective functions depend on features of the package design and packaging materials. Below are the main protective functions of medical device packaging:

Physical Protection

- Safeguard against impact, vibration, and mechanical stress: Medical equipment needs to be safeguarded against physical impact, vibration, and mechanical stress. These potential risks in the healthcare sector can cause serious losses through damaging equipment. Protective packaging comes with excellent package strength and functionality to safeguard devices from impactful damage, mechanical stress, and vibrations.

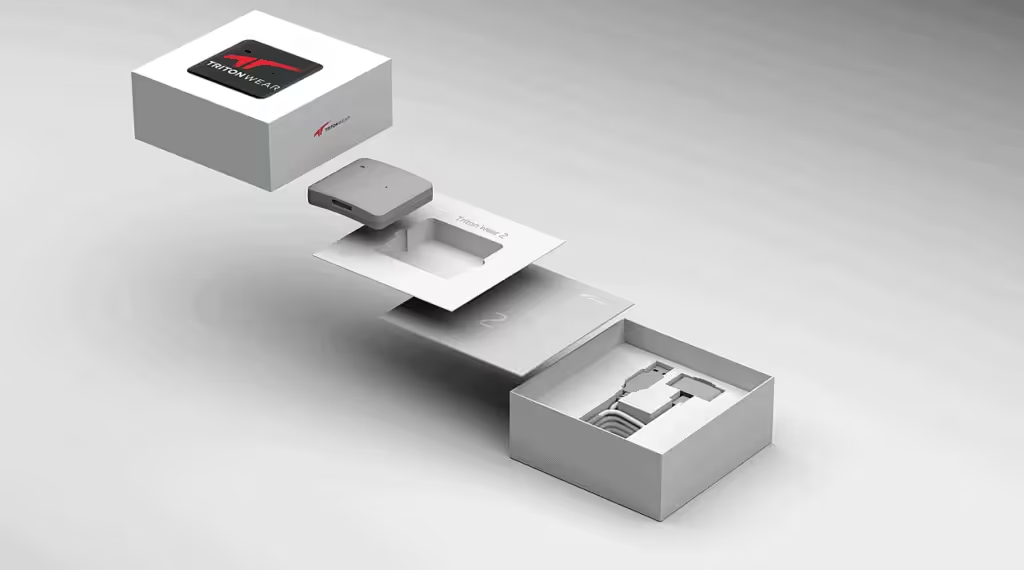

- Provide cushioning and shock absorption: To protect equipment from various shocks, the medical device packaging is made of special material that deforms and crushes to absorb shock and dampen vibrations rather than transmitting vibrations to the packaged device. This cushioning effect is effective and ensures end users receive the items undamaged.

Chemical Protection

- Selecting materials that prevent interaction with the device: Medical equipment packaging is important in ensuring devices are safe and secure. This also includes how the packaging material reacts to the packaged device. Most medical industry packaging solutions are made of materials that do not interact with the equipment. An improper packaging made of reactive materials will compromise the machine’s integrity.

- Proper consideration of the sterilization process: During the sterilization process, medical device packaging is a critical component to protect devices from chemicals. The sterilization method is an important process before devices are unpacked. Medical device packaging is designed to allow penetration of sterilizing agents while maintaining the device’s integrity for the intended shelf life.

- Compliance with requirements for chemical compatibility and leachability: The medical industry uses healthcare product packaging solutions that are chemically compatible with the device. The materials used in manufacturing the packaging are non-toxic, odorless, and non-leaching. This means the materials in the medical packaging industry are chemically inert to the equipment.

Biological Protection

- Understanding the risks of microbial contamination and infection associated: One of the main functions of medical device protective packaging is to protect the device from microbial or biological contamination. Microbial contamination can sacrifice the integrity and sterility of equipment. It is caused by microbes like bacteria, fungi, protozoa, yeast, and even virus, and they can cause a number of infections, including strep throat, pertussis, MRSA infection, tetanus, and more. Medical equipment packaging permit sterilization, preventing microbial contamination of the devices.

- Implementation of sterile packaging systems: To prevent biological contamination and harm, the adoption of sterile packaging systems is necessary. This will ensure the device is safeguarded from any biological threat throughout its usage in the hospital or shipment.

Environmental Protection

- Exploring sustainable packaging options: Environmental sustainability has been a major subject in almost every industry. The need for sustainable solutions cannot be ignored; the medical sector has a great stake in this. Over the years, plastic materials have dominated packaging solutions for medical products. Although some forms of plastic are recyclable, plastics have formed a major part of solid waste. Alternative materials that produce less environmental harm can be adopted for packaging solutions. Paper, cardboard, bioplastics, cornstarch material, etc., are sustainable options to substitute plastics like polyethylene and PVC.

- Integrating eco-friendly and recyclable materials in packaging design: Eco-friendly and recyclable materials offer many benefits. They are biodegradable and compostable while at the same time cost-effective in manufacturing healthcare packages. By integrating recyclable materials in package design, waste will significantly reduce, making our environment more friendly and sustainable.

Considerations in Medical Device Packaging

There are numerous considerations when looking for proper packaging for medical applications, like medicine during production. Below, we outline some of the most outstanding considerations that every business owner should follow. These considerations provide flexible packaging solutions and optimal protective layers for medical applications.

Adherence o International Standards for Medical Device Packaging

When considering medical device packaging, you must understand, acknowledge, and comply with international standards and regulations. The Food and Drug Administration (FDA) recognized regulations have three main pillars; forming and sealing of packaging consistently, robust packaging to withstand transport and environmental hazards, and packaging integrity. These regulations must be followed and adhered to for successful medical product packaging.

Collaboration with Packaging Manufacturers to meet Regulatory Requirements

The medical product packaging process can be complex. Doing it by yourself can be a big task and challenging. By collaborating with an expert manufacturer, you can get specialist advice on the type of packaging to use depending on your product value and details about its benefits and costs involved.

Identify the Most Appropriate Packaging Material for Specific Medical Devices

Various packaging materials are available, but each serves its purpose depending on the product in question. Also, choose a packaging material compatible with your products’ value and packaging requirements.

Conclusion

Medical items are more advanced and costly today, and the packaging is as crucial as the product. Packaging offers a number of benefits, but the most important are safety and security. The protective functions of packaging in handling medical items are immense, but the material used in manufacturing it must conform to environmental goals.

At Packoi, we are committed to helping businesses with custom packaging designs conforming to your business values and customer needs. To get design services, contact us or click the button below for more details regarding our services.